Low-carbon waterborne coating and preparation method thereof

A carbon water-based coating technology, applied in fire-resistant coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of long drying time, high production cost, complicated process, etc., and achieve short drying time, low cost, flexibility Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

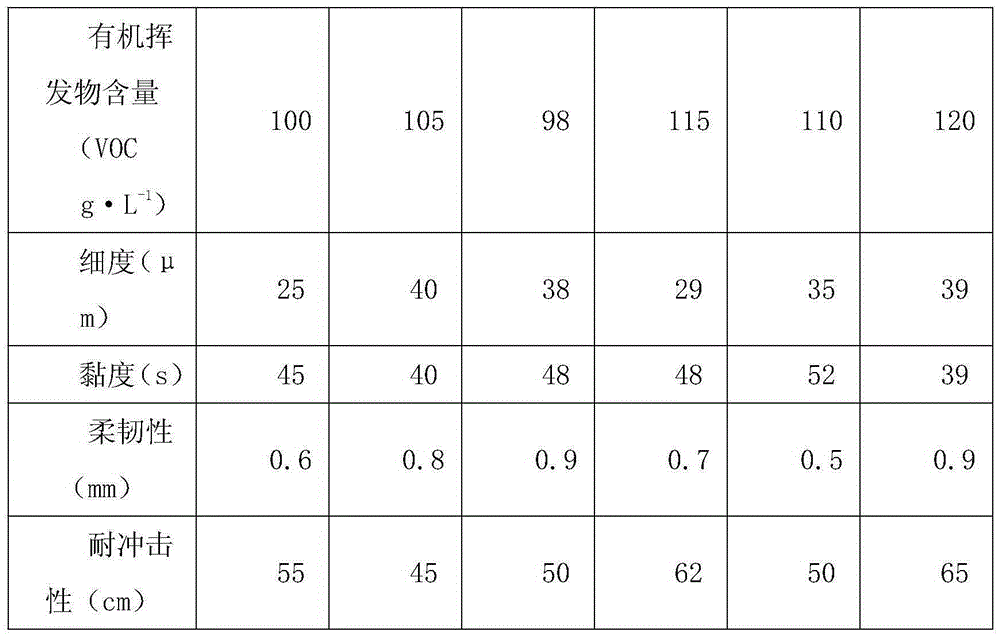

Embodiment 1

[0026] Recipe: The low-carbon water-based paint is composed of the following components by weight: 50 parts of polyurethane, 22 parts of polyaniline and aluminum paste mixture, 12 parts of talcum powder, 0.3 part of rheological agent, 0.2 part of polyvinyl alcohol, substrate moistening 0.2 parts of wet agent, 0.3 parts of anti-settling agent, 0.4 parts of defoamer, 0.3 parts of thickener, 0.2 parts of leveling agent, 2 parts of composite flame retardant of organic phosphorus-nitrogen flame retardant and organic silicon flame retardant , 6 parts of isocyanates, 60 parts of deionized water; the pigment-base ratio of the coating is 0.44.

[0027] The preparation method of described low-carbon water-based coating comprises the steps:

[0028] (1) Add the deionized water, 30% polyurethane, polyaniline and aluminum paste mixture, talcum powder, rheological agent, polyvinyl alcohol, and substrate wetting agent into the batching tank in order, and the stirring speed Stir at 1200 rpm ...

Embodiment 2

[0031] Recipe: The low-carbon water-based paint is composed of the following components by weight: 60 parts of acrylic resin, 24 parts of polyaniline, a mixture of aluminum silver paste and metal powder, 12 parts of barium sulfate, 0.5 parts of rheological agent, polyvinyl pyrrolidine 0.3 parts of ketones, 0.3 parts of substrate wetting agents, 0.5 parts of anti-settling agents, 0.4 parts of defoamers, 0.3 parts of thickeners, 0.4 parts of leveling agents, organic phosphorus-nitrogen flame retardants and silicone flame retardants 4 parts of composite flame retardants, 18 parts of isocyanates, and 50 parts of deionized water; the pigment-base ratio of the coating is 0.6.

[0032] The preparation method of described low-carbon water-based coating comprises the steps:

[0033] (1) Wet the deionized water, 40% acrylic resin, polyaniline, aluminum silver paste and metal powder, barium sulfate, rheological agent, polyvinylpyrrolidone, and base material in order. Add the agent into ...

Embodiment 3

[0036] Formula: low-carbon water-based paint is composed of the following components by weight: 55 parts of acrylic modified polyurethane emulsion PUA, 26 parts of polyaniline and aluminum-silver paste mixture, 16 parts of mica powder, 0.5 parts of rheological agent, and 0.4 parts of polyacrylamide , 0.4 parts of substrate wetting agent, 0.3 parts of anti-settling agent, 0.4 parts of defoaming agent, 0.5 parts of thickener, 0.5 parts of leveling agent, organic phosphorus-nitrogen flame retardant and silicone flame retardant 4 parts of fuel, 18 parts of alcohol ether solvent, 75 parts of deionized water; the pigment-base ratio of the coating is 0.47.

[0037] The preparation method of described low-carbon water-based coating comprises the steps:

[0038](1) Add deionized water, 30% acrylic modified polyurethane emulsion PUA, polyaniline and aluminum-silver paste mixture, mica powder, rheological agent, polypropylene phthaloamide, and substrate wetting agent in order in order I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com