A kind of conductive paste for back electrode of silicon solar cell and preparation method thereof

A technology for silicon solar cells and back electrodes, which is used in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc. Problems such as reducing the conductivity of the back electrode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Add 15 grams of ethyl cellulose and 5 grams of phenolic resin to a mixed solution of 10 grams of terpineol, 55 grams of diethylene glycol butyl ether, and 10 grams of tributyl citrate, and heat it at 50 ° C to 80 ° C Disperse and mix evenly to form a clear and transparent organic carrier for later use; take 20 grams of the above organic carrier, add 75 grams of silver powder, 15 grams of aluminum powder, 4 grams of silver-gold-germanium alloy powder with a melting point of 450 ° C, and 1 gram of gallium, and mix well , and then use a three-roll grinder to grind 3 times to make a conductive paste for the front electrode of a crystalline silicon solar cell.

Embodiment 2

[0032] Add 15 grams of ethyl cellulose and 5 grams of phenolic resin to a mixed solution of 10 grams of terpineol, 55 grams of diethylene glycol butyl ether, and 10 grams of tributyl citrate, and heat it at 50 ° C to 80 ° C Disperse and mix evenly to form a clear and transparent organic carrier for later use; take 15 grams of the above organic carrier, add 40 grams of silver powder, 10 grams of silver-coated copper powder with a silver weight content of 25%, 15 grams of aluminum powder, and 5 grams of silver with a melting point of 450 ° C. - gold-germanium alloy powder, 1 gram of gallium, fully mixed evenly, and then ground three times with a three-roll mill to make a conductive paste for the front electrode of a crystalline silicon solar cell.

Embodiment 3

[0034] Add 20 grams of ethyl cellulose to a mixed solution of 10 grams of terpineol, 60 grams of diethylene glycol butyl ether, and 10 grams of tributyl citrate, and disperse and mix evenly at 50 ° C ~ 80 ° C to form a clear The transparent organic carrier is ready for use; take 20 grams of the above organic carrier, add 50 grams of silver powder, 20 grams of aluminum powder, 5 grams of silver-gold-germanium alloy powder with a melting point of 450 ° C, 2 grams of simple boron, mix well, and then use three rollers to The grinder grinds 3 times to make the conductive paste for the front electrode of the crystalline silicon solar cell.

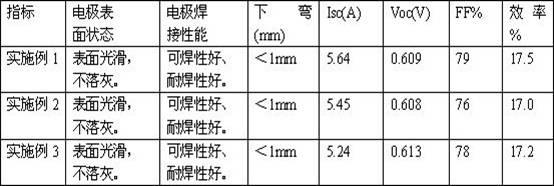

[0035] The prepared conductive paste for the front electrode of the crystalline silicon solar cell is screen-printed, dried and co-sintered on the crystalline silicon solar cell production line to form a crystalline silicon solar cell, and the surface state of the crystalline silicon solar cell is observed and measured. Solderability, solder res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com