Double-shell epoxy resin microcapsule self-repair material and preparation method thereof

A technology of self-healing materials and epoxy resin, which is applied in the direction of microcapsule preparation and microsphere preparation, can solve the problems of adverse effects on stability, poor acid and alkali resistance, poor compatibility, etc., and achieve good chemical stability and Thermal stability, compact structure, and excellent coating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

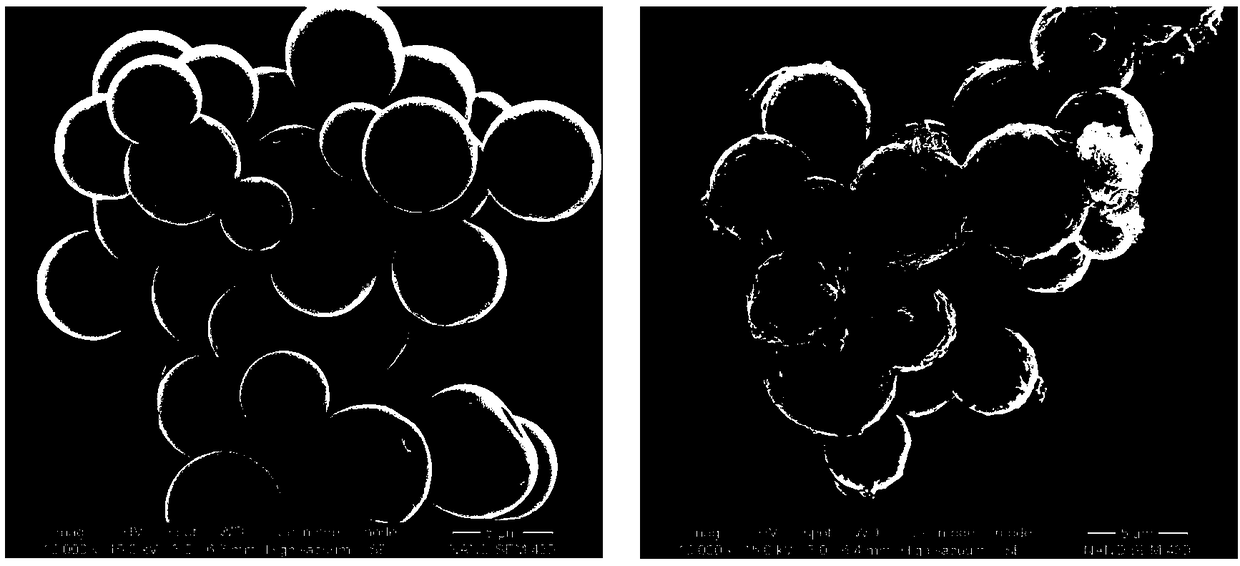

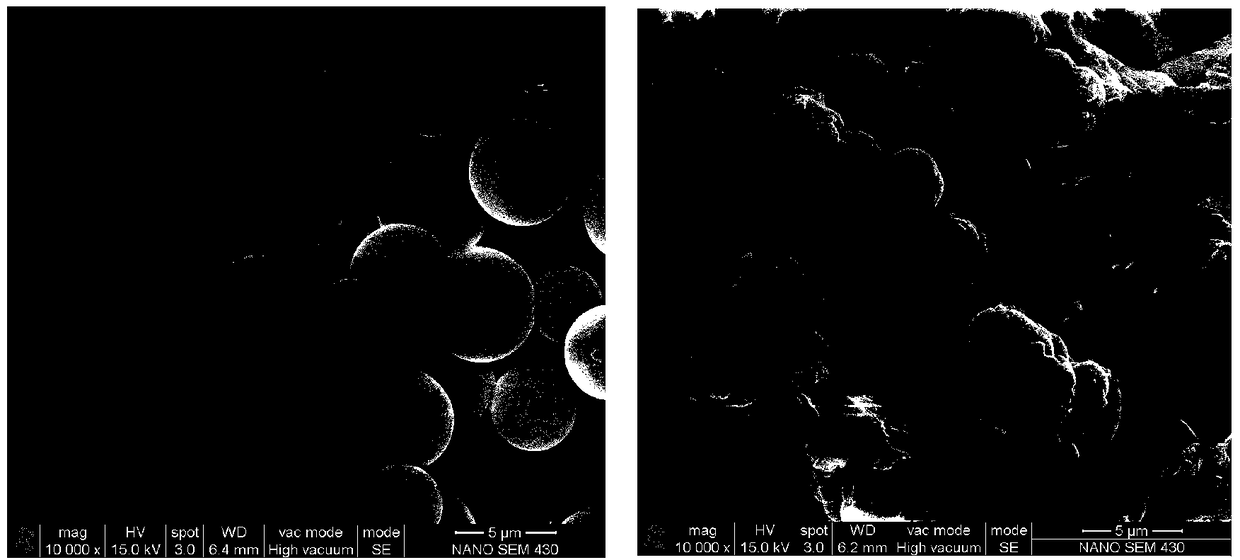

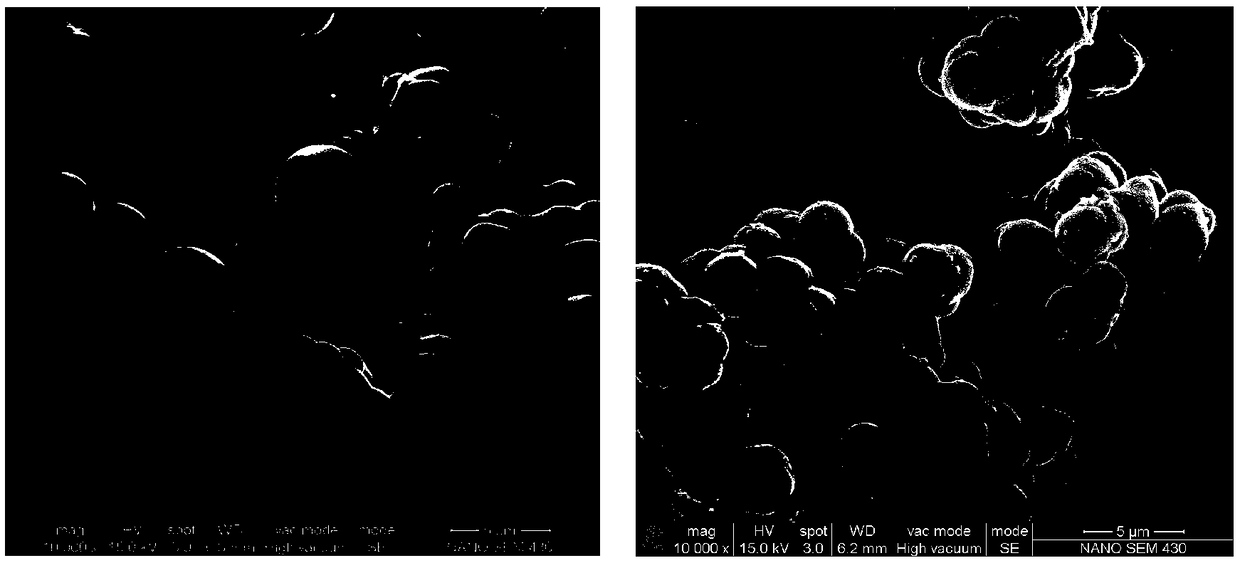

Image

Examples

Embodiment 1

[0032] A double-shell epoxy resin microcapsule self-repairing material and a preparation method thereof, comprising the following steps:

[0033] (1) 30g of bisphenol A type epoxy resin (E51), 4.5g of butyl glycidyl ether and 15ml of graphene oxide aqueous dispersion, under 80 ℃ of water bath temperature, with 3000r / min emulsification shear stirring 30min, in In this process, drop 60ml of deionized water to form an epoxy resin emulsion, and adjust the pH value of the emulsion to 3-4 with citric acid solution of 10% mass concentration;

[0034] (2) After mixing 4g melamine, 8g urea, and 27g formaldehyde solution, stir magnetically at a water bath temperature of 70°C, adjust the pH value of the mixed solution system to 9-10 with 10% mass concentration of sodium hydroxide solution, and add 30ml deionized water , stirring for 1 h to obtain a viscous transparent urea-formaldehyde prepolymer to generate a low molecular weight water-soluble prepolymer solution;

[0035] (3) Preparat...

Embodiment 2

[0038] A double-shell epoxy resin microcapsule self-repairing material and a preparation method thereof, comprising the following steps:

[0039] (1) 20g of bisphenol A type epoxy resin epoxy resin ((E44), 2.4g of butyl glycidyl ether and 15ml of graphene oxide aqueous dispersion are emulsified and sheared at 2000r / min at a water bath temperature of 85°C Stir for 30 minutes, drop 60ml of deionized water in the process to form an epoxy resin emulsion, adjust the pH of the emulsion to 3-4 with 10% mass concentration of hydrochloric acid;

[0040] (2) After mixing 3 g of melamine, 9 g of urea, and 27 g of formaldehyde solution, stir magnetically at a water bath temperature of 70 ° C, adjust the pH value of the mixed solution system to 9-10 with 10% triethanolamine solution, add 30 ml of deionized water, and stir for 1 h Obtain a viscous transparent urea-formaldehyde prepolymer to generate a low molecular weight water-soluble prepolymer solution;

[0041] (3) Preparation of epoxy...

Embodiment 3

[0044] A double-shell epoxy resin microcapsule self-repairing material and a preparation method thereof, comprising the following steps:

[0045] (1) 10g of bisphenol A type epoxy resin epoxy resin ((E51), 1.5g of butyl glycidyl ether and 15ml of graphene oxide aqueous dispersion are emulsified and sheared at 4000r / min at a water bath temperature of 75°C Stir for 30 minutes, drop 60ml of deionized water in the process to form an epoxy resin emulsion, and adjust the pH of the emulsion to 3-4 with 10% citric acid solution;

[0046] (2) After mixing 2 g of melamine, 10 g of urea, and 27 g of formaldehyde solution, stir magnetically at a water bath temperature of 70 ° C, adjust the pH value of the mixed solution system to 9-10 with 10% sodium carbonate solution, add 30 ml of deionized water, and stir for 1 h Obtain a viscous transparent urea-formaldehyde prepolymer to generate a low molecular weight water-soluble prepolymer solution;

[0047] (3) Preparation of epoxy resin microc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com