Preparation method of lithium ion battery anode material FeV2O4

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, chemical instruments and methods, etc., can solve problems such as poor performance, and achieve the effects of capacity decay, increased tap density, and good cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

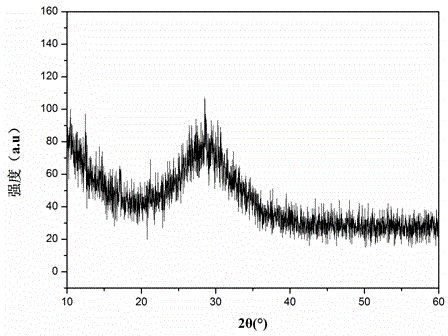

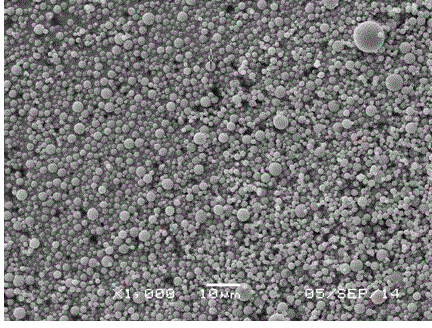

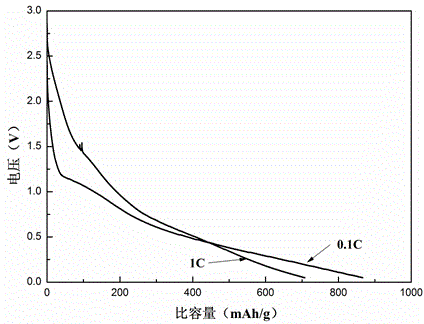

Image

Examples

Embodiment 1

[0026] (1) Dissolve 0.01mol ferrous oxalate in 100mL of deionized water to make a solution with a concentration of 0.1mol / L; dissolve 0.02mol of ammonium metavanadate in 100mL of deionized water to make a solution with a concentration of 0.2mol / L solution; then at the same time, the prepared ferrous oxalate solution and ammonium metavanadate solution were added to the stirred reactor at a rate of 400mL / h under an atmosphere of high-purity nitrogen (concentration ≥ 99.99%), and the stirring speed was controlled to 300rpm. After the addition, adjust the pH to 5 with ammonia water, and continue the reaction for 2 hours to obtain a dark blue suspension; (2) Add 4 mL of ethanol to the suspension obtained in step (1), and then spray dry it at a feed rate of 800 mL / h, the drying air inlet temperature is 220°C, and the air outlet temperature is 120°C to obtain the precursor material; (3) the precursor material obtained in step (2) is under the protection of high-purity nitrogen (conce...

Embodiment 2

[0030] (1) Dissolve 0.01mol ferrous oxalate in 100mL of deionized water to make a solution with a concentration of 0.1mol / L; dissolve 0.02mol of ammonium metavanadate in 100mL of deionized water to make a solution with a concentration of 0.2mol / L solution; then at the same time, add ferrous oxalate solution and ammonium metavanadate solution to the stirred reactor at a speed of 200mL / h under the atmosphere of high-purity argon (concentration ≥ 99.99%), and control the stirring speed to 200rpm , adjust the pH to 2 with ammonia water after the addition, and continue the reaction for 1 hour to obtain a dark blue suspension; (2) Add 2 mL of ethanol to the suspension obtained in step (1), and then spray dry it at a feed rate of 400 mL / h, the drying inlet air temperature is 150°C, and the outlet air temperature is 80°C to obtain the precursor material; (3) the precursor material obtained in step (2) is protected by high-purity argon (concentration ≥ 99.99%) Heat treatment at 200°C f...

Embodiment 3

[0033] (1) Dissolve 0.01mol ferrous oxalate in 100mL of deionized water to make a solution with a concentration of 0.1mol / L; dissolve 0.02mol of ammonium metavanadate in 100mL of deionized water to make a solution with a concentration of 0.2mol / L solution; then at the same time, add ferrous oxalate solution and ammonium metavanadate solution to the stirred reactor at a speed of 600mL / h under the atmosphere of high-purity argon (concentration ≥ 99.99%), and control the stirring speed to 400rpm , after the addition, adjust the pH to 6 with ammonia water, and continue the reaction for 4 hours to obtain a dark blue suspension; (2) Add 6 mL of ethanol to the suspension obtained in step (1), and then spray dry it at a feed rate of 1200 mL / h, the drying inlet air temperature is 250°C, and the outlet air temperature is 150°C to obtain the precursor material; (3) the precursor material obtained in step (2) is protected by high-purity argon (concentration ≥ 99.99%) Heat treatment at 400...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com