Cement polyphenyl granule concrete lattice composite wall shuttering, its manufacturing method, lattice composite wall and its manufacturing method

A technology of polystyrene particles and composite walls, which is applied to building structures, walls, building components, etc., can solve the problems of complicated operation procedures and flammable insulation materials, and achieve cost reduction, improved dispersion, and increased tensile strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

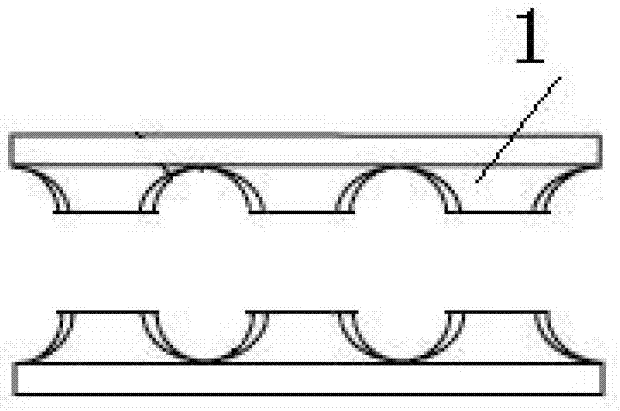

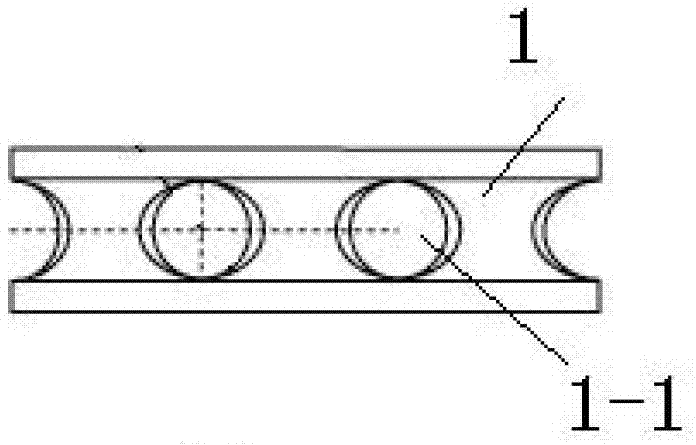

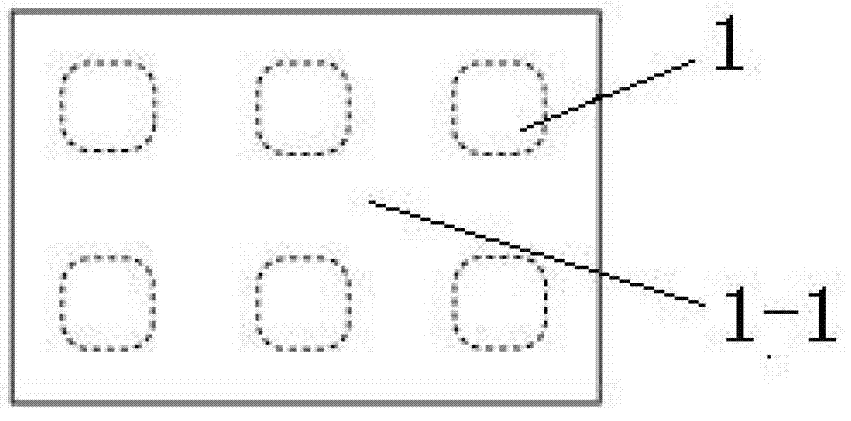

[0012] Specific implementation mode one: the following combination figure 1 This embodiment will be specifically described. In this embodiment, the cement polyphenylene particle concrete lattice type composite wall formwork includes the following components under the unit total volume: polyphenylene particle: 12-18Kg, cement: 260-320Kg, fly ash or slag 0~ 70Kg, mold shell interface agent: 0.50~0.65Kg, water; 120~150Kg.

[0013] The manufacturing method of cement polystyrene particle concrete lattice type composite wall formwork, it is finished by the following steps: a, polyphenylene particle: 12~18Kg, cement: 260~320Kg, fly ash: 0~70Kg, mix and stir Make cement polystyrene granular mixture; b. After diluting 0.50~0.65Kg of mold shell interface agent with 120~150Kg water, add in the above cement polystyrene granular mixture and stir to make cement polyphenyl granular concrete; c. The finished cement polyphenylene particle concrete is poured in the mold and pressed into a hal...

specific Embodiment approach 2

[0016] Specific embodiment two: the cement polyphenylene particle concrete lattice type composite wall formwork of the present embodiment comprises the following components: polyphenylene particle: 15Kg, cement: 320Kg, fly ash 35Kg, formwork interface agent: 0.575Kg, Water: 135Kg.

specific Embodiment approach 3

[0017] Specific embodiment three: the cement-polyphenylene particle concrete lattice composite wall formwork of this embodiment includes the following components: polystyrene particle: 13Kg, cement: 261Kg, fly ash: 1Kg, formwork interface agent: 0.51Kg , Water: 121Kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com