Comfort spandex fiber and preparation method thereof

A spandex fiber, comfortable technology, applied in the field of functional chemical fiber and its manufacturing, to achieve the effect of saving oil removal process, low modulus, and sufficient separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

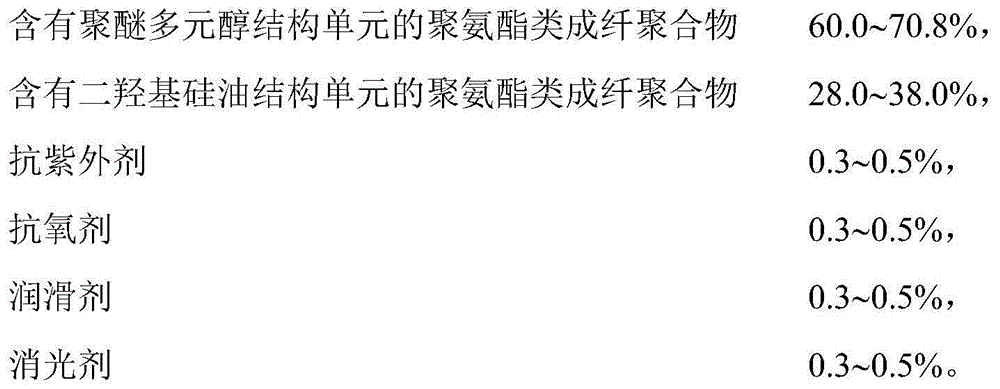

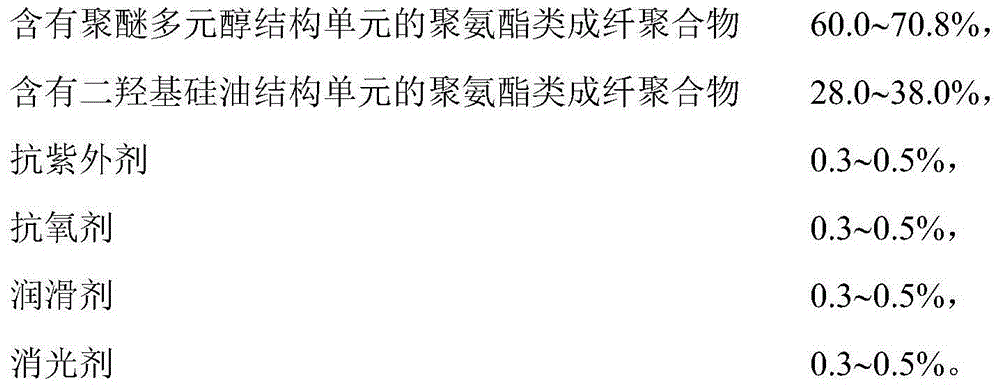

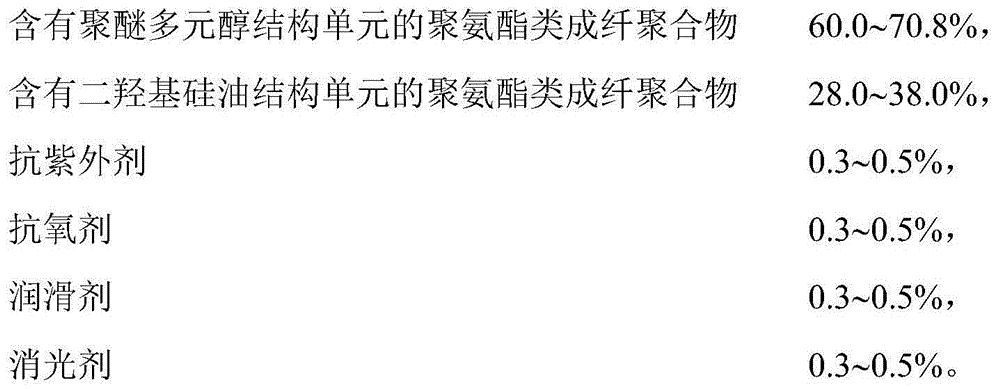

Method used

Image

Examples

Embodiment 1

[0023] Step 1: Prepare mixed prepolymer solution

[0024] 1) Prepare a prepolymer solution containing polyether polyol structural units: prepolymerize at 90° C. for 90 minutes with the molar ratio of diisocyanate and polytetrahydrofuran diol at 1.7, and add N to the prepolymer after the prepolymerization is completed, N-dimethylacetamide solvent is made into the prepolymer solution that mass percent concentration is 50%;

[0025] 2) Prepare a prepolymer solution containing dihydroxysilicone oil structural units: prepolymerize at 95°C for 100 min with the molar ratio of diisocyanate to dihydroxysilicone oil at 1.7, and add N,N- The dimethylacetamide solvent is prepared into a prepolymer solution with a concentration of 50% by mass; wherein the relative molecular weight of the dihydroxy silicone oil is 2500.

[0026] 3) Prepare a mixed prepolymer solution: blend the prepolymer solution of step 1) and step 2) at 40° C. for 35 minutes to prepare a mixed prepolymer solution;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| resilience | aaaaa | aaaaa |

| resilience | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com