Multi-functional blocking remover and preparation method thereof

A plug-removing agent and multi-functional technology, applied in the field of multi-functional plug-removing agent and its preparation, can solve the problems of high transportation cost, easy volatilization, strong corrosion, etc., and achieve simple construction process, wide application temperature and low corrosion rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

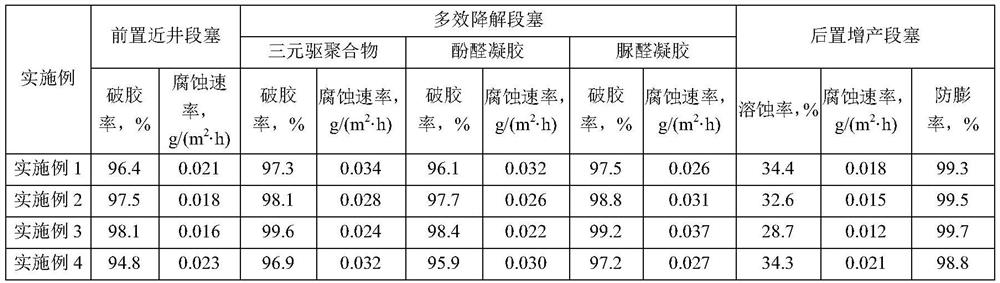

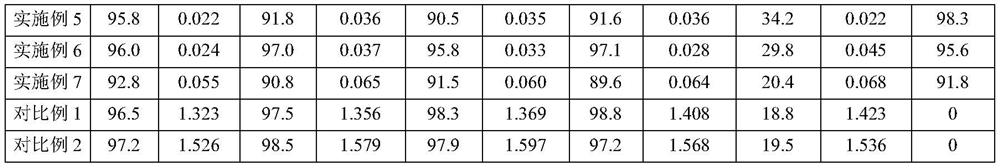

Examples

preparation example Construction

[0049] According to a typical embodiment of the present invention, a method for preparing a multifunctional plugging remover is provided, including the step of preparing a pre-near-well plugging-removing agent, and the preparation of a pre-near-well plugging-removing agent includes: Accurately weigh each component, add osmotic dispersant and stir until completely dissolved in oilfield produced water, then add instant solvent and stir until completely dissolved.

[0050] Preferably, the preparation method also includes the step of preparing a multi-effect degradation slug release agent. The preparation of the multi-effect degradation slug release agent includes: accurately weighing each component according to the weight percentage, and using After the oilfield produced water is dissolved and stirred to dissolve, add chelating agent, activator, double coupling agent and biological agent in sequence and stir to dissolve evenly;

[0051] Preferably, the preparation method also inc...

Embodiment 1

[0056] This embodiment provides a multifunctional plugging remover. The multifunctional plugging removal agent step by step includes a front-end near-well plugging removal agent, a multi-effect degradation plugging removal agent, and a post-production stimulation plugging removal agent.

[0057] Wherein the pre-near wellbore plugging remover consists of the following components in weight percentage:

[0058] Osmotic dispersant, 1%;

[0059] Fast solvent, 0.2%;

[0060] Oilfield produced water, balance.

[0061] The osmotic dispersant is a mixture of octanamidopropyl dimethyl amine oxide, nonylphenol polyoxyethylene ether maleate ethyltrimethylammonium chloride and sodium ricinoleate. Taking the penetration dispersant as 100%, the mass percentage of octanamidopropyl dimethyl amine oxide is 20%, and the mass percentage of nonylphenol polyoxyethylene ether maleate ethyl trimethyl ammonium chloride is 10%, and the mass percentage of sodium coricinoleate is 70%.

[0062] The fa...

Embodiment 2

[0089] This embodiment provides a multifunctional plugging remover. The multifunctional plugging removal agent step by step includes a front-end near-well plugging removal agent, a multi-effect degradation plugging removal agent, and a post-production stimulation plugging removal agent.

[0090] Wherein the pre-near wellbore plugging remover consists of the following components in weight percentage:

[0091] Osmotic dispersant, 1.5%;

[0092] Fast solvent, 0.3%;

[0093] Oilfield produced water, balance.

[0094] The osmotic dispersant is a mixture of octanamidopropyl dimethyl amine oxide, nonylphenol polyoxyethylene ether maleate ethyl trimethyl ammonium chloride and sodium ricinoleate. Taking the penetration dispersant as 100%, the mass percentage of octanamidopropyl dimethyl amine oxide is 30%, and the mass percentage of nonylphenol polyoxyethylene ether maleate ethyl trimethyl ammonium chloride is 20%, the mass percentage of sodium coricinoleate is 50%.

[0095] The fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com