Patents

Literature

38 results about "Sodium ricinoleate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium ricinoleate is the sodium salt of ricinoleic acid, the principal fatty acid derived from castor oil. It is used in making soap, where its molecular structure causes it to lather more easily than comparable sodium soaps derived from fatty acids. It is a bactericide. It exhibits several polymorphic structural phases.

Sodium ricinoleate organic modified sodium-based montmorillonite and application thereof in hard polyurethane

InactiveCN102604161AGood dispersionImprove thermal stabilityPigment treatment with non-polymer organic compoundsSodium ricinoleateMontmorillonite

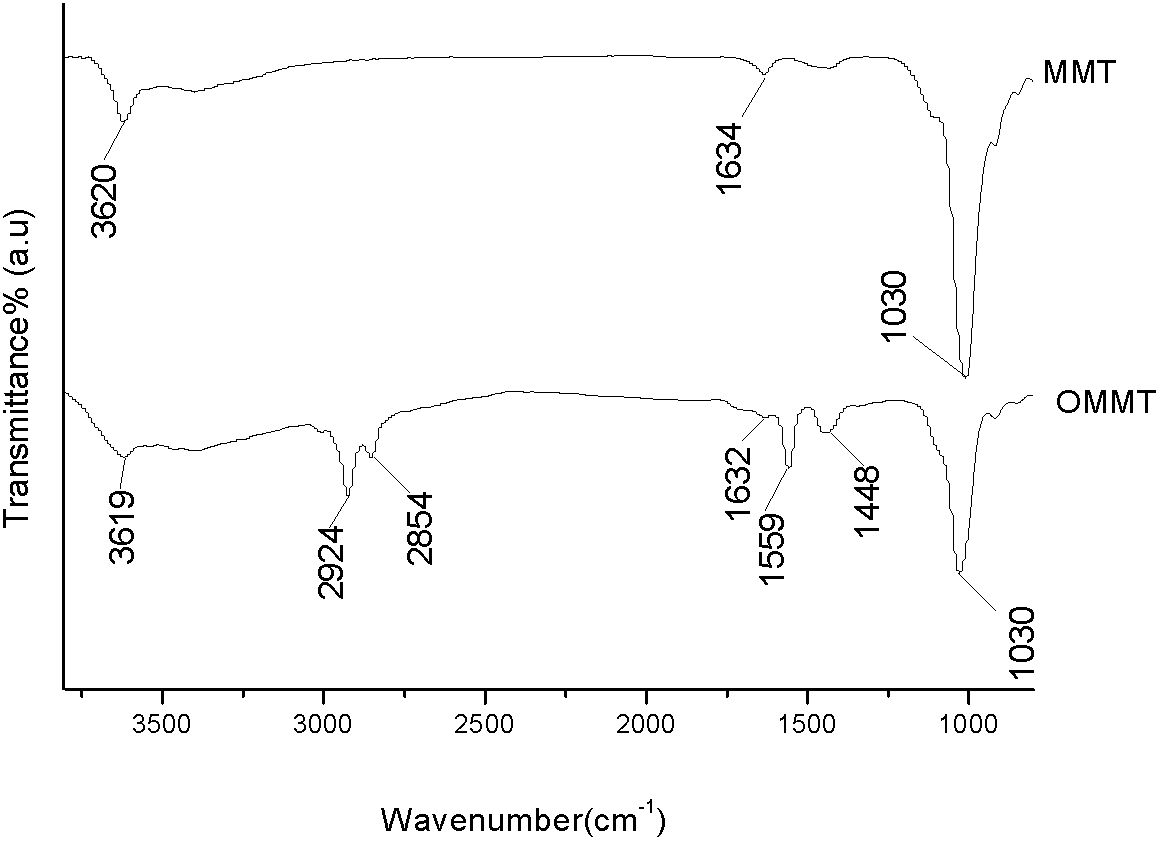

The invention discloses sodium ricinoleate organic modified sodium-based montmorillonite and an application thereof in hard polyurethane. The layer spacings of the sodium ricinoleate organic modified sodium-based montmorillonite are 4-5nm, and the sodium ricinoleate organic modified sodium-based montmorillonite structure contains an active hydroxy. According to the invention, sodium-based montmorillonite is modified with a common method by using sodium ricinoleate, such that the sodium ricinoleate organic modified sodium-based montmorillonite is obtained. According to the invention, a 3-8 wt% solution is prepared by using sodium-based montmorillonite; a pH value of the reaction liquid is regulated to 5.5-13; the reaction liquid is heated to a temperature for 50-80 DEG C, and is emulsified for 3-4h; 0.5-3CEC of obtained sodium ricinoleate is added to the reaction liquid, and the mixture is subject to a reaction for 3-4h, such that the sodium ricinoleate organic modified sodium-based montmorillonite is prepared. Polyurethane foamed plastic prepared with the sodium ricinoleate organic modified sodium-based montmorillonite has higher thermal stability, higher fire retardance, and higher mechanical properties.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

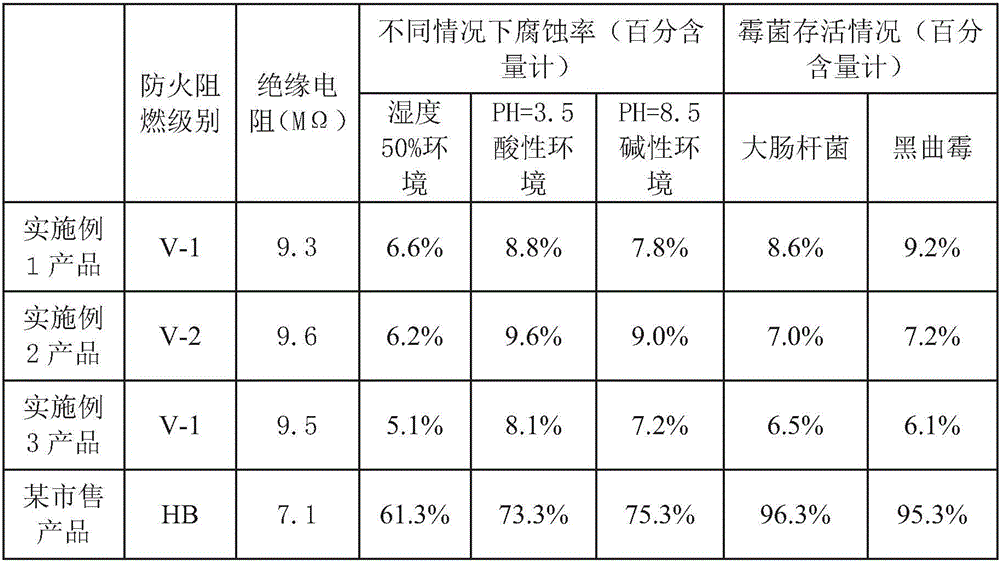

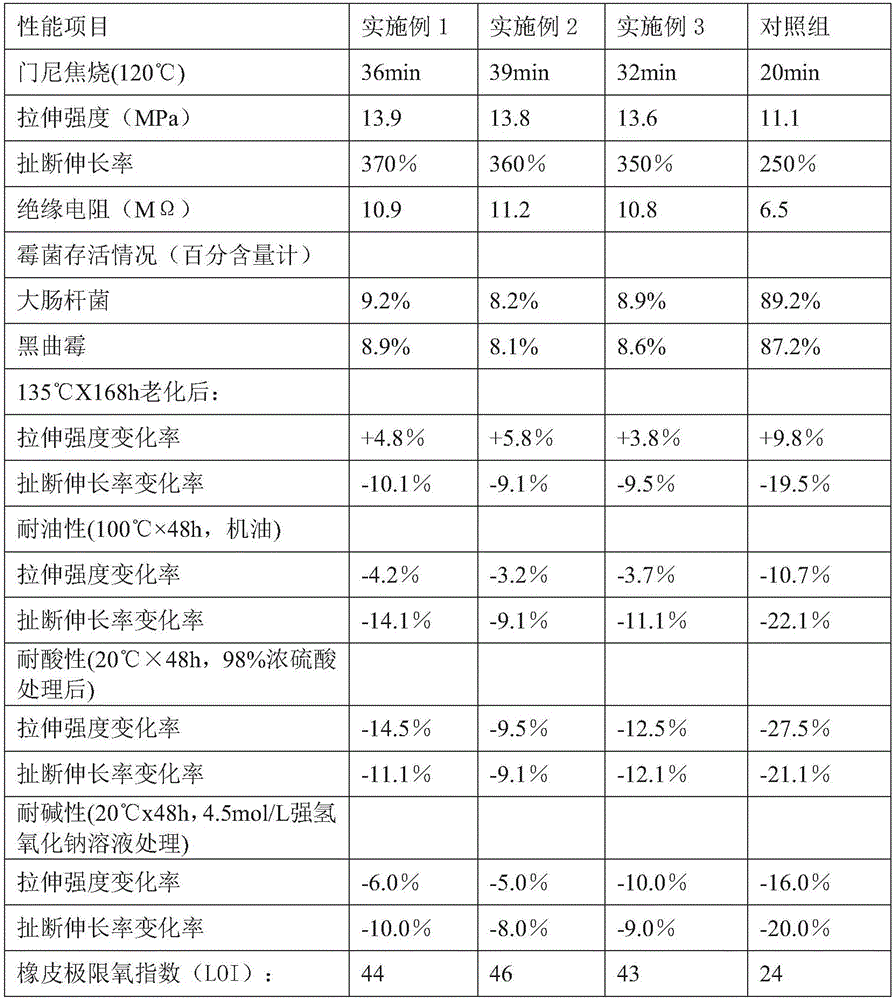

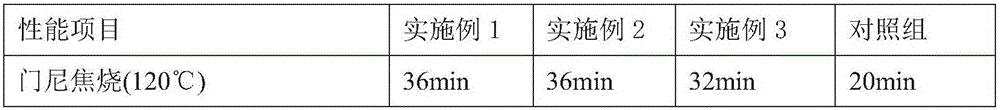

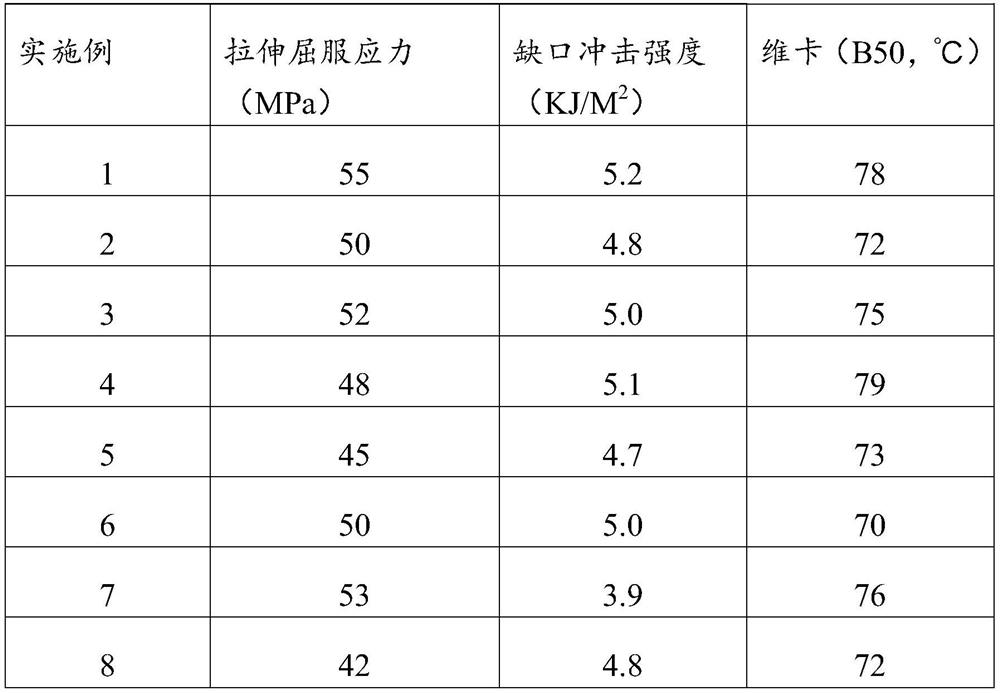

Flame-retarding, acid-alkali-resisting wear-resisting fire hose material

InactiveCN106349721AExcellent flame retardantExcellent flame retardant acid and alkali resistanceDecabromobiphenyl etherDecabromodiphenyl ether

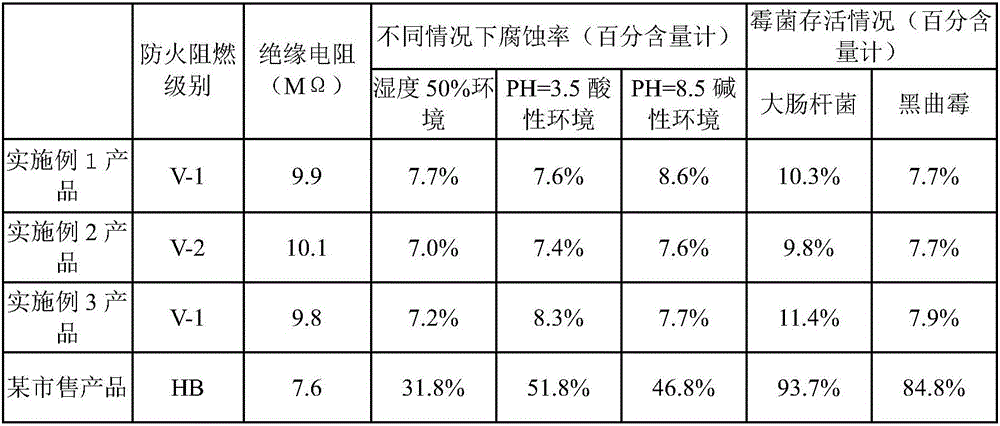

The invention relates to a flame-retarding, acid-alkali-resisting wear-resisting fire hose material. The flame-retarding, acid-alkali-resisting wear-resisting fire hose material is prepared from rosin resin, p-tert-octyl phenolformaldehyde resin, amino resin, polyethylene wax emulsion, tall oil fatty acid, butyl acetate, isoamyl propionate, diethylene glycol dimethyl ether, dimethyl fumarate, sodium perborate, imidazoline, ammonium fluosilicate, guanidine phosphate powder, phenyl triethoxy silane, sodium pyrophosphate, chromium oxide, chromium chloride, menthol, barium chromate powder, ferrous orthophosphate, ethylenedioxydiethyl bis, tricresol phosphate ester, decabromodiphenyl ether, nanometer magnesium hydroxide, lignin, morpholine, polyoxyethylene polyoxy propyl alcohol amine ether, alkyl polyglucoside, propylamine, sodium ricinoleic acid. The product has excellent flame retardance, acid-base resistance, anti-mildew and anti-microbial performances, and the product performance is improved.

Owner:袁华

Fireproof oil paint

InactiveCN104927647AImprove insulation performanceImprove adhesionFireproof paintsXylyleneColloidal silica

The invention discloses fireproof oil paint. The fireproof oil paint is prepared from, by weight, 12-26 parts of organic silicone resin, 2-4 parts of asbestos, 4-6 parts of acrylic resin, 1-3 parts of fluorinated ethylene propylene copolymer, 1-2 parts of leveling agent, 3-4 parts of sodium silicate, 2-6 parts of borax, 3-4.5 parts of sodium ricinoleate, 4-6 parts of colloidal silica, 5-10 parts of butyl stearate, 6-12 parts of fireproof materials, 7-14 parts of dehydrated castor oil, 2-5 parts of chlorinated paraffin, 3-6 parts of methyl ether, 12-16 parts of xylene and 4-6 parts of lavenders. The fireproof oil paint has the advantages of excellent electric insulativity, high adhesive force, effectiveness in prevention of cracking and shedding, extremely excellent fireproof effects and accordance with market demands.

Owner:QINGDAO ENGAO MOTION CONTROL TECH

Foaming injection material for automobile steering wheels and preparation method thereof

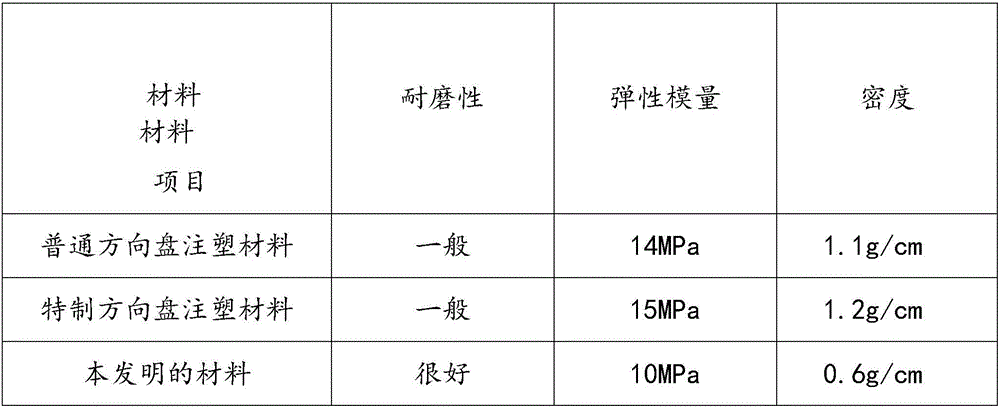

The invention discloses a foaming injection material for automobile steering wheels. The foaming injection material for automobile steering wheels is prepared from the materials in parts by weight: 55-62 parts of polyurethane, 19-24 parts of ethylene-vinyl acetate copolymer, 8-16 parts of polypropylene, 22-25 parts of aromatic polycarbonate, 16-20 parts of sodium carbonate, 35-40 parts of difluorodifluoromethane, 6-8 parts of lauryl sodium sulfate, 11-14 parts of isocyanate, 23-25 parts of sodium ricinoleate, 17-20 parts of polyether glycol, 8-10 parts of sorbitol, 7-11 parts of mica powder, 23-24 parts of sodium pyrophosphate, 6-9 parts of ammonium polyphosphate, 11-14 parts of stearic acid, 13-16 parts of polyethylene polyamine, 2-4 parts of butadiene and 8-10 parts of silicon dioxide. The foaming injection material for automobile steering wheels has the advantages of favorable elasticity, light weight and favorable wear-resistant effect.

Owner:芜湖天鸿汽车零部件有限公司

Artistically-designed package film material

InactiveCN105837999AThe preparation process is simpleExcellent flame retardantPolymer sciencePolyvinyl chloride

The invention relates to an artistic design packaging film material, which is composed of the following components: barium petroleum sulfonate, zinc ethyl phenyl dithiocarbamate, vermiculite powder, phenyl dichlorophosphate, zeolite powder, ethoxyquin Phenoline, Sodium Metabisulfite, Disodium Octaborate Tetrahydrate, Diacylglycerol, Magnesium Oxide, Polyvinyl Chloride Resin, Polydimethylsiloxane, Tricresyl Phosphate, Diatomaceous Earth, Carbendazim, Phosphite, Polyurethane Rubber powder, Phytectin, Polycarbonate, Sodium Ricinoleate, Ethylene Glycol Salicylate, Styrene Acrylic Emulsion, Imperata. The art design packaging film material has a simple preparation process, and the prepared product has relatively superior flame retardancy, acid and alkali resistance, anti-mildew and antibacterial properties, and improves product performance.

Owner:孟根森

Finishing agent for textiles

InactiveCN104878600AGood hydrophilic functionImprove washabilityFibre treatmentPolymer scienceDiethylenetriamine

A finishing agent for textiles is prepared from the following raw materials in parts by weight: 12-22 parts of sulfonate starch, 5-7 parts of ethyl valerate, 10-14 parts of sodium ricinoleate, 2-3.5 parts of oxidized polyethlene wax, 1.5-2.6 parts of imidazoline N-hexadecyltrimethylammonium chloride, 1.2-2.3 parts of lavender essence, 2-3 parts of diethylenetriamine, 8-12 parts of amino silicon oil, 5-8 parts of isophorone diisocyanate, 7-14 parts of polyoxyethylene, 6-9 parts of sodium cetanol sulfate, 3-7 parts of ammonium lauryl sulfate and 2-4 parts of water-soluble lanolin. The finishing agent has the following benefits: the finishing agent for textiles can ensure that the textiles are good in hydrophilic function, have better wash fastness and anti-static property, and enables fabric to be hygroscopic and sweat releasing.

Owner:QINGDAO DONGCHANGRUI TEXTILE

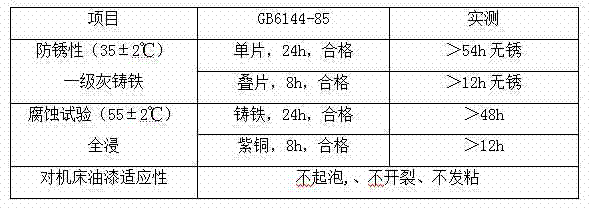

Water-based metal wire drawing liquid with good lubricating effect and preparation method thereof

InactiveCN104263486AMeet brightness requirementsMeet the dimensional accuracy requirementsLubricant compositionWater basedCoconut diethanolamide

The invention discloses a water-based metal wire drawing liquid with a good lubricating effect. The water-based metal wire drawing liquid is characterized in that the water-based metal wire drawing liquid is prepared from the following raw materials in parts by weight: 3-4 parts of sodium ricinoleate soap, 1-2 parts of coconut diethanolamide, 1.5-2 parts of polyepoxysuccinic acid, 5-7 parts of sulfurized lard oil, 3-4 parts of polyethylene glycol, 3-4.5 parts of sodium hydrogen carbonate, 3-5 parts of chlorinated paraffin, 3-4 parts of spindle oil, 2-4 parts of sodium carboxymethyl cellulose, 0.8-1.5 parts of sodium benzoate, 5-7 parts of additives and 900-950 parts of deionized water. The water-based metal wire drawing liquid disclosed by the invention has excellent lubricating performance and can meet the requirements of customers on brightness and dimensional precision at relatively low concentration; by adding the additives, the water-based metal wire drawing liquid has good wear resistance, dispersion, lubrication and film-forming property, is mutually matched with a surfactant, and can form a protective film on the surface of a metal to realize a corrosion inhibition effect. The water-based metal wire drawing liquid adopts a water-based formula, is good in cooling property and cleaning property, is easy to be moved after processing, and further ensures the cleanliness of a wire drawing operation environment.

Owner:ANHUI WANGDA COPPER DEV

Surface treatment method of nano-sized titanium dioxide

InactiveCN107118593AGood dispersionImprove stabilityNanotechnologyPigment physical treatmentSodium ricinoleateWeather resistance

The invention discloses a surface treatment method of nano-sized titanium dioxide. The surface treatment method comprises the following steps: conveying nano-sized titanium dioxide into a surface treatment tank, then adding a barium stearate dispersant and water, controlling the temperature to be 60-80 DEG C, and stirring for 20-30 min at the rotating speed of 100-300 r / min to obtain a nano-sized titanium dioxide dispersion; adding the nano-sized titanium dioxide dispersion into an ultrasonic generator, then adding a sodium ricinoleate sulfate and sodium tripolyphosphate compound modifier, and performing ultrasonic treatment for 20-40 min at the temperature of 60-80 DEG C and the frequency of 60-80 Hz to obtain a modified nano-sized titanium dioxide solution; and filtering, drying, crushing and sieving the modified nano-sized titanium dioxide solution to complete modification of nano-sized titanium dioxide. Nano-sized titanium dioxide obtained after surface treatment by the surface treatment method is not only high in dispersion, high in stability and high in compatibility with an organic matter, but also can improve the light resistance and the weather resistance of titanium dioxide.

Owner:LIUZHOU BOZE SCI & TECH

Formula of low-toxicity polystyrene adhesive

InactiveCN104263286ARaw materials are easy to getLow priceNon-macromolecular adhesive additivesMacromolecular adhesive additivesCyclohexanonePolyvinyl alcohol

The invention relates to a formula of a low-toxicity polystyrene adhesive. The low-toxicity polystyrene adhesive comprises the following components: 70 parts of polystyrene, sodium dodecyl benzene sulfonate, 2 parts of sodium water glass, 5 parts of methylbenzene, 7 parts of sulfonated sodium ricinoleate, 5 parts of polyacrylate, 7 parts of sodium hydroxide, 7 parts of ethylene-vinyl acetate copolymers, 5 parts of ethyl acetate, 5 parts of cyclohexanone, 7 parts of polyvinyl alcohol and 7 parts of dimethyl carbonate. The environment-friendly polystyrene adhesive provided by the invention is available in raw material, low in price, simple in preparation process and capable of reducing pollution, and has the advantages of low price, favorable adhesive force, acid and alkali resistance and no environment pollution.

Owner:QINGDAO HI TECH PATENT TECH TRANSFER PLATFORM

Water-based cutting fluid stable in quality and uniform to disperse and preparation method of water-based cutting fluid

The invention discloses a water-based cutting fluid stable in quality and uniform to disperse. The water-based cutting fluid is characterized by being prepared from the following raw materials in parts by weight: 1-2 parts of sodium molybdate, 2-3 parts of triethanolamine, 1.5-2.5 parts of carboxylic acid, 3.5-5 parts of polysorbate-80, 2-4 parts of castor oil, 4-5 parts of sodium ricinoleate, 2-3 parts of tartaric acid, 6-8 parts of nanosilicon dioxide, 2-3 parts of octadecylamine N-oleoyl sarcosinate, 5-7 parts of an auxiliary and 200 parts of deionized water. According to the water-based cutting fluid, a grinding material nanosilicon dioxide and a surfactant are mixed, so that not only is the wear resistance enhanced, but also the grinding material is uniform to disperse, thereby promoting the quality of the cutting fluid. Matched with the auxiliary, the wear resistance, dispersibility, lubricity and film-forming property of the cutting fluid are enhanced. The cutting fluid disclosed by the invention has excellent lubricating and wear resisting performance, cleaning cooling performance and anti-rust corrosion resisting performance, can avoid generation of built-up edges and effectively protects cutters and improves the processing quality. The cutting fluid is simple to operate and low in cost.

Owner:XUZHOU SANHE AUTOMATIC CONTROL EQUIP

Power cable for solar photovoltaic power distribution cabinet

InactiveCN106046713ASoft textureExcellent flame retardantInsulated cablesInsulated conductorsPhosphateWear resistant

The invention relates to a power cable for a solar photovoltaic power distribution cabinet. The power cable comprises a plurality of copper alloy conductive wires and a plurality of protective sleeves, wherein the copper alloy conductive wires are arranged in parallel; each copper alloy conductive wire is enwrapped by the protective sleeve, and the protective sleeve comprises the following components: polybutylene terephthalate, ethylene propylene rubber, isoprene rubber, ethylenediamine tetramethylenephosphonic acid, dimethyl formamide, cottonseed oil, phosphate, eucalyptus oil, bronopol, garlic oil, tea polyphenol, ceramic powder, zeolite powder, lead oxide powder, sodium carbonate, calcium phosphate powder, vermiculite powder, dolomite powder, honey, polyethylene wax, triethylene glycol bis(2-ethylhexanoate), p-cresol, polyacrylonitrile fiber, polyoxyethylene oleate, vinyl benzene, cobalt isooctoate, sodium ricinate, a sulfenamide accelerator, p-toluenesulfonic acid and lauryl methacrylate. The power cable is soft in texture, wear-resistant, high temperature-resistant, safe and reliable, and has relatively excellent flame-retardant, acid-resistant, alkali-resistant, mildew-proof and antibacterial performance.

Owner:李斌

Adhesive for semiconductor diode assembling

InactiveCN106118547AImprove anti-aging propertiesImprove temperature adaptation rangeNon-macromolecular adhesive additivesPolyether adhesivesSodium phosphatesPolyvinyl alcohol

The invention relates to an adhesive for semiconductor diode assembly, which is composed of the following components: sodium alkylbenzene sulfonate azobisisobutylcyanide, sodium antimonate, montmorillonite, polycarbonate, dibutyl phthalate Ester, chlorosulfonated polyethylene, trioctyl trimellitate, triethanolamine borate, nano calcium carbonate, hexamethylenetetramine, zirconia powder, dibasic lead stearate, polyethylene terephthalate Diethyl formate, wollastonite powder, pearl powder, methyl silicone resin, sodium melamine phosphate, polypropylene, talc, polyethylene glycol, fatty alcohol polyoxyethylene ether, polyvinyl alcohol, sodium ricinoleate, copper oxalate , lead dibasic phthalate, polyamideimide, phosphite, polyvinyl chloride resin. The raw materials used in the present invention have a synergistic effect, which greatly improves the anti-aging performance of the binder and improves the temperature adaptability range of the binder, and the temperature adaptability range is -80-250°C.

Owner:王璐

Automatic control cabinet used for large ship

InactiveCN104774574AReasonable structureImprove work performanceNon-macromolecular adhesive additivesMetal layered productsSodium ricinoleateBenzoic acid

The invention discloses an automatic control cabinet used for a large ship. A cabinet body is formed by multiple adjacent metal plates in an adhering mode. Adhesive is composed of 2-hydroxy-2-butanone, benzoic acid, sodium ricinoleate, saccharin and fumed silica. The automatic control cabinet is reasonable in structure, good in seal performance and good in working effect, and the adjacent plates are firm.

Owner:NANTONG CHANGHANG SHIP FITTINGS

Multifunctional cable for municipal ecological garden construction

InactiveCN106084642ASoft textureExcellent flame retardantInsulated cablesInsulated conductorsPolychlorinated biphenylSodium phosphates

The invention relates to a multifunctional cable for municipal ecological garden construction. The multifunctional cable comprises a plurality of copper alloy wires and protecting covers, the copper alloy wires are arranged in parallel, and the outer layers of all the copper alloy wires are covered with the protecting covers. The protecting covers are prepared from p-tert-octyl phenolformaldehyde resin, fluorosilicon resin, fluororubber, pure acrylic emulsion, butyl acetate, lauryl alcohol phosphate acid ester, spindle oil, dipropylene glycol methyl ether, sodium monofluorophosphate, ethyl p-hydroxybenzoate, didecyl dimethyl ammonium chloride, dibromomethane, corn starch, sodium phosphate, calcium sulphate dehydrate, glass fiber powder, aluminium nitride powder, sodium tetraborate decahydrate, quartz powder, magnesium sulfate, polyethylene wax, trioctyl phosphate, polychlorinated biphenyl, ammonium polyphosphate, sodium ricinoleate, butyraldehyde, polyethylene polyamine, nickel dibutyldithiocarbamate, chlorothalonil and lead sulfate tribasic. By means of the multifunctional cable for municipal ecological garden construction, the using performance of the product is improved.

Owner:王志英

Multifunctional waterborne additive with wetting and thickening functions, and manufacturing method thereof

The invention discloses a multifunctional waterborne additive with wetting and thickening functions, and a manufacturing method thereof. The multifunctional waterborne additive comprises, by mass, 5-20 parts of a nonionic wetting agent which is a propylene oxide-ethylene oxide copolymer F38, 1-10 parts of an anionic surfactant and a long-chain terminator which are sodium ricinoleate, 5-20 parts ofhydroxy organosilicon, 0-50 parts of an alcohol ether solvent PMA, 10-40 parts of a polyol, 5-30 parts of diisocyanates HDI and IPDI, 1-20 parts of a chain extender diol BDO, 2-20 parts of a carboxylglycol and 1-15 parts of amine. The additive can integrate two separate functions by chemical bonds in order to avoid performance interference and improve the stability, so multiple functions are realized by one additive, so the batching process is reduced, and the use cost is reduced.

Owner:清远市美佳乐环保新材股份有限公司

Leather sofa detergent added with sapindus saponin

InactiveCN105296246AEfficient removalLess corrosiveSurface-active non-soap compounds and soap mixture detergentsLeather surface finishingSulfonateSodium ricinoleate

The invention discloses a leather sofa detergent added with sapindus saponin. The leather sofa detergent is prepared from, by weight, 12-18 parts of fatty methyl ester sulfonates, 10-15 parts of sapindus saponin, 4-7 parts of sodium ricinoleate soap, 5-8 parts of rhamnolipid, 4-6 parts of sodium carbonate, 5-10 parts of sodium tripolyphosphate, 8-12 parts of tall oil, 14-22 parts of cocoamido propyl hydroxy sulfobetaine, 4-6 parts of 1,3-dimethyl-2-imidazolone, 5-10 parts of dodecyl dimethyl benzyl ammonium chloride, 7-11 parts of secondary alkyl sodium sulfonate, 10-15 parts of N-polyoxyethylated-N-tallow-alkylamine and 70-80 parts of water. The leather sofa detergent can effectively remove dirt, further has the bactericidal, antibacterial, environmentally friendly, pollution-free, small-leather-corrosivity advantages and meanwhile can improve the softness of leather sofa.

Owner:MINGGUANG LIANGYU FURNITURE CO LTD

Novel fabric deodorant and preparation method thereof

PendingCN112359596ACause fadingCause discoloration damageBiochemical treatment with enzymes/microorganismsXylyleneSodium ricinoleate

The invention discloses a novel fabric deodorant and a preparation method thereof, and relates to the technical field of deodorants. The novel fabric deodorant is prepared from the following raw materials in parts by weight: 0.8-1.2 parts of a surfactant, 0.3-0.5 part of sodium xylene sulfonate, 0.5-0.7 part of sodium citrate, 0.08-0.12 part of sodium hydroxide, 0.08-0.12 part of citric acid, 0.04-0.06 part of a preservative, 0.08-0.12 part of a penetrating agent, 0.08-0.12 part of a complexing agent, 1.8-2.2 parts of ethanol, 0.7-0.9 part of castor oil, 0.008-0.012 part of sodium ricinoleate,0.8-1.2 parts of bio-enzyme and 92.84-94.84 parts of deionized water. The invention relates to the technical field of deodorants, in particular to an environment-friendly deodorant. According to thenovel fabric deodorant and the preparation method thereof, by adding the sodium xylene sulfonate, the sodium citrate, the sodium hydroxide, the preservative, the complexing agent, the ethanol, the castor oil, the sodium ricinoleate and the bio-enzyme, fading and discoloring damage to fabric are avoided, rapid permeation and rapid reaction can be achieved by adding the penetrating agent, an obviousdeodorant effect on various fabric peculiar smells is achieved, and the preparation process is simple and easy to operate.

Owner:合肥艾尔纳新材料科技有限公司

Safety protection cover material of smart phone

The invention relates to a smart phone safety protective cover material, which is composed of the following components: perchlorethylene resin, a-olefin elastomer, acrylic ester resin, trichloroethyl phosphate, polybenzimidazole imide, decabromodi Ethylene phenylene, trioctyl phosphate, dibenzofuran, calcium propionate, sodium monofluorophosphate, methylisothiazolinone, polyhexamethyleneguanidine, disodium hydrogen phosphate, barium sulfate powder, lead oxide powder, Barite powder, molybdenum disulfide powder, soda ash, lead iodate powder, fly ash, calcium phosphate powder, praseodymium oxide powder, polyether modified silicone oil, methyl isobutyl ketone, trimethyl borate, sodium ricinoleate , hydroxyethyl acrylate, butyraldehyde, p-toluenesulfonic acid, alkyl polyglucoside. The product of the invention has relatively superior flame retardancy, acid and alkali resistance, anti-mildew and antibacterial properties, and improves product performance.

Owner:王根夫

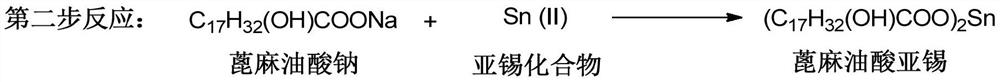

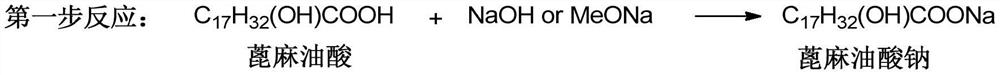

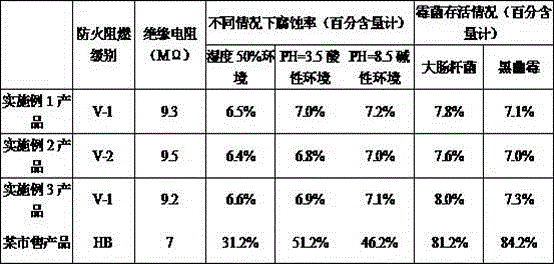

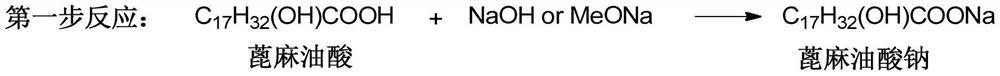

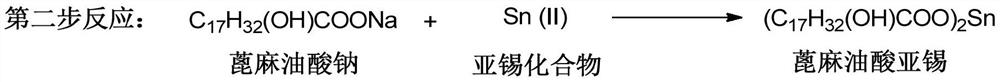

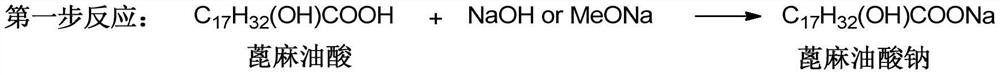

Synthetic method of stannous ricinoleate

ActiveCN112574025ALow costSimple and fast operationOrganic compound preparationCarboxylic acid salt preparationSodium methoxideHydration reaction

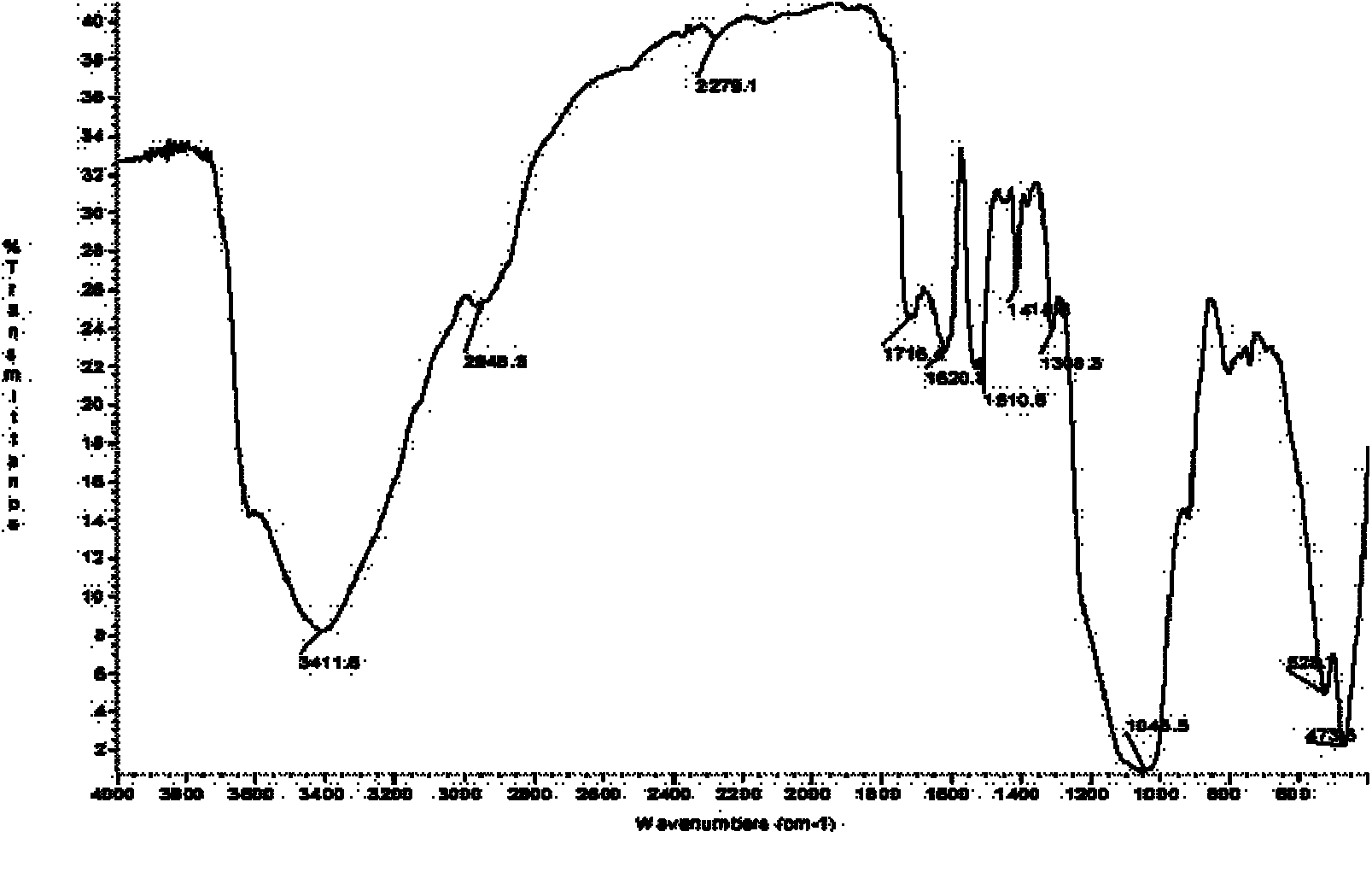

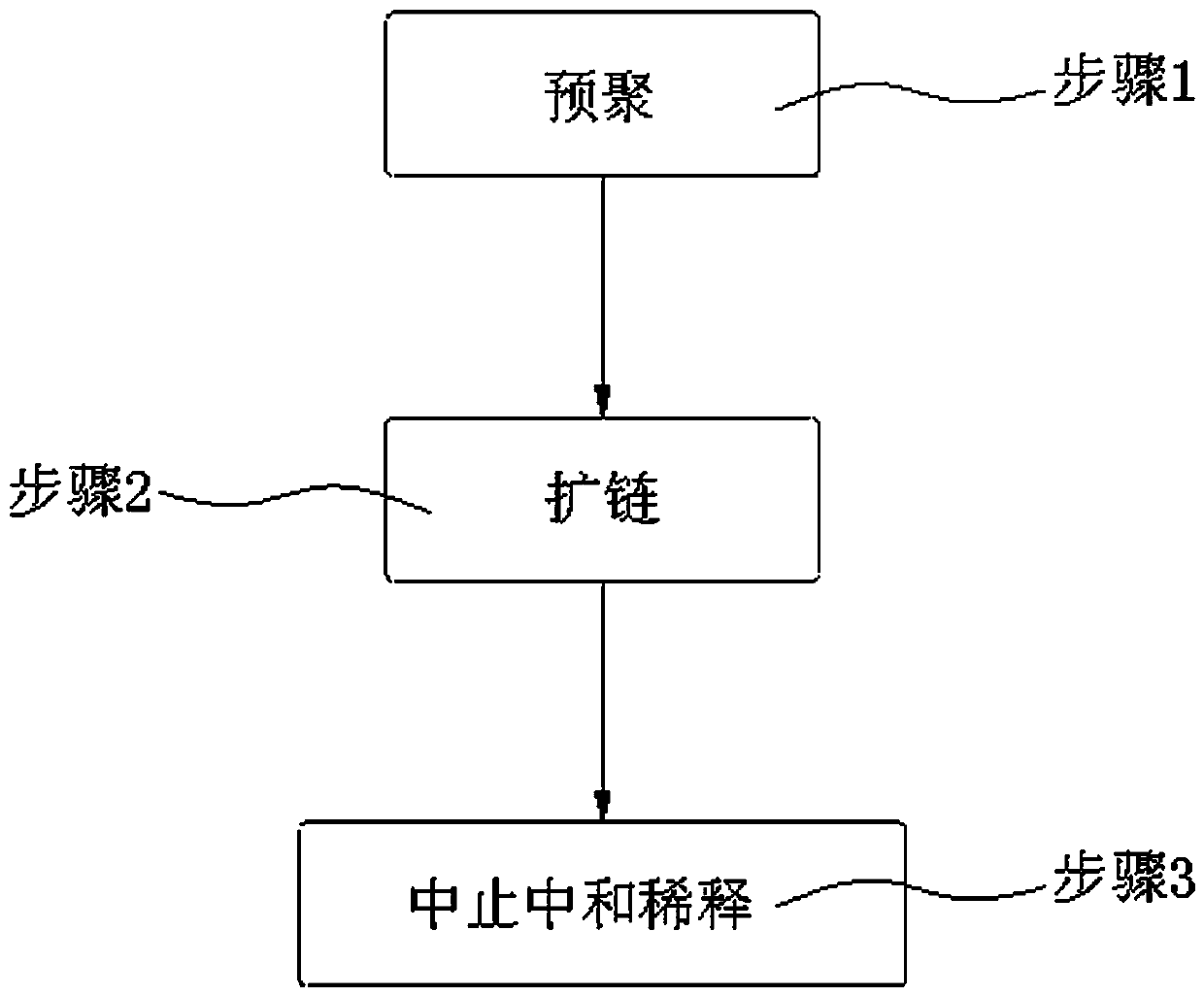

The invention discloses a synthetic method of stannous ricinoleate. According to the method, two steps of reactions are adopted, ricinoleic acid is used as a raw material in the first step of reaction, and a solvent A is used for reacting with sodium hydroxide, sodium methoxide or a sodium methoxide methanol solution under certain reaction conditions to synthesize sodium ricinoleate; and in the second step of reaction, the sodium ricinoleate is used as a raw material to react with anhydrous stannous chloride, stannous chloride hydrate or stannous sulfate by using a solvent B under a heating condition to synthesize stannous ricinoleate. The solvent A is an alcohol solvent; the solvent B is an alcohol solvent, an aromatic solvent or a polar aprotic solvent; and the solvent A and the solventB can be recovered by a distillation method and can be recycled. The method has the advantages of low raw material cost, simple operation, less discharge of three wastes, high reaction efficiency andthe like.

Owner:SHANGHAI MAIPU NEW MATERIAL TECH CO LTD

Turning, grinding, milling universal emulsion cutting oil, and production method thereof

InactiveCN104711104AImprove cooling effectImprove the lubrication effectLubricant compositionWater qualityBalance water

The invention discloses a turning, grinding, milling universal emulsion cutting oil. The turning, grinding, milling universal emulsion cutting oil is prepared from following raw materials, by mass, 10 to 15% of petroleum sodium sulfonate, 10 to 15% of barium petroleum sulfonate, 4 to 8% of sodium ricinoleate, 4 to 6% of triethanolamine oleic soap, 1 to 2% of NP-6, 18 to 22% of No.32 machine oil, 0.1 to 0.5% of an antifoaming agent, 4 to 6% of a phosphatized water quality conditioning agent, and the balance water. A production method comprises following steps: weighed water is delivered into a reaction vessel, and is heated to 70 to 80 DEG C; a stirrer is turned on, and rotating speed is controlled to be 40r / min; weighed petroleum sodium sulfonate, barium petroleum sulfonate, sodium ricinoleate, triethanolamine oleic soap, NP-6, No.32 machine oil, the antifoaming agent, and the phosphatized water quality conditioning agent are delivered into the reaction vessel slowly and successively, wherein after adding of each of the raw materials, stirring is carried out for 30min, and after adding of all the raw materials, stirring is carried out for another 3 to 4h; an obtained mixture is cooled to room temperature, and is collected, filtered, and packaged.

Owner:DALIAN SANDAAOKE CHEM

Preparation method of nano calcium carbonate reinforced and toughened PVC

PendingCN114437472AAchieve decentralizationImprove heat resistanceSodium ricinoleatePolyvinyl chloride

The invention discloses a preparation method of nano calcium carbonate reinforced and toughened PVC (polyvinyl chloride), which comprises the following steps: (1) dissolving sodium ricinoleate sulfate in water, and carrying out ultrasonic oscillation at room temperature for 5-10 minutes to obtain a solution A; dissolving silicon salt in an ethanol solution to obtain a solution B; (2) adding alkali into the solution B in a stirring state, carrying out ultrasonic oscillation, then adding diethanol amine, and continuously carrying out ultrasonic treatment to be mixed with the solution A, so as to obtain a surface treating agent; (3) adding a surface treating agent into the nano calcium carbonate suspension, heating for reaction, washing and drying to obtain modified nano calcium carbonate; and (4) mixing the modified nano calcium carbonate, PVC resin and auxiliary materials according to a certain proportion, curing, extruding and cooling to obtain the product. According to the invention, the nano calcium carbonate suspension is subjected to wet surface modification by adopting the surface modifier, and the toughened PVC nano composite material is prepared by compounding PVC and nano calcium carbonate, so that the strength and rigidity are improved while toughening is realized, and the heat resistance of the material is improved.

Owner:广西雄塑科技发展有限公司

Lubricating oil and preparation method thereof

The invention discloses lubricating oil, which comprises the following components in part by weight: 90 to 93 parts of engine oil of over SH level, 0.1 to 0.3 part of potassium isooctanoate, 0.1 to 0.3 part of sodium sulforicinolate, 1.0 to 1.4 parts of alkyl calcium salicylate, 1.5 to 2 parts of alkyl thiophosphate and 3.7 parts of polybutene succinamide. A preparation method for the lubricating oil comprises the following steps: (1) adding the components into a reaction kettle according to the formulation in turn, heating and stirring the components at the same time, and preserving the temperature at about 55 DEG C; (2) after all the components are uniformly mixed, filtering the mixture with a viscous solution filter; and (3) adding 0.3 to 1.5 parts of additives into the mixture. The additives comprise 0.1 to 0.5 part of viscosity improver, 0.1 to 0.5 part of pour point reducer and 0.1 to 0.5 part of anti-foaming agent.

Owner:SHAANXI ZHONGDA ENERGY TECH

Printing ink for advertising art design packing paper

InactiveCN106479265AExcellent flame retardantGood acid and alkali resistanceInksMethylanilineSucrose

The invention relates to printing ink for advertising art design packing paper. The printing ink is prepared from components as follows: methylaniline, iminoctadine tris(albesilate), lead iodate powder, chlorothalonil, dolomite powder, garlic oil, sodium phosphate, methyl isobutyl carbinol, methyl benzoylformate, polyether modified silicone oil, tert-butyl hydroperoxide, sucrose, an acrylonitrile-butadiene-styrene copolymer, nitrile butadiene rubber powder, dibasic lead stearate, hexabromocyclododecane, hydrated zinc borate, calcium hypochlorite, menthol, glass powder, diphenylmethane diisocyanate, molybdenum disilicide powder, beryllium oxide powder, oxidized paraffin, propylene glycol monomethyl ether, a polyacrylic acid emulsion, linseed oil, sodium ricinoleate, lauryl mercaptan and bisphenol A diglycidyl ether. The product has excellent flame-retardant, acid-base-resistant, anti-mildew and antibacterial properties, and the product performance is improved.

Owner:FOSHAN RENHE TECH CO LTD

Enzyme crystal ball soap and preparation method thereof

InactiveCN109929704ASimple production processLow costSoap detergents with organic compounding agentsDetergent compounding agentsSodium ricinoleateDipropylene glycol

The invention discloses enzyme crystal ball soap and a preparation method thereof, and relates to the technical field of soap. The enzyme crystal ball soap is prepared from the following components inpercentage by weight: 15%-25% of glycerin, 14%-21% of sodium palmitate, 12%-20% of sodium cocoate, 4%-10% of dipropylene glycol, 3%-9% of sodium ricinoleate, 0.5%-1.5% of sorbitol, 0.5%-1.5% of microadded components, and the balance of deionized water, the materials are evenly mixed and heated, and the enzyme crystal ball soap can be obtained. According to the enzyme crystal ball soap, during using, the skin can be cleaned, polysaccharides and enzymes in the components can gentle and relax the skin, prevent skin aging and repair the skin, using needs are met, and the ball soap is simple in production process, low in equipment cost, and high in production efficiency.

Owner:轻妍合生(天津)国际贸易有限公司

A kind of building exterior wall thermal insulation coating

ActiveCN107868530BLow thermal conductivityImprove thermal conductivityPolyester coatingsSodium ricinoleateEmulsion

The invention discloses a heat insulation coating applied to building exterior walls and relates to the technical field of coatings. The heat insulation coating is prepared from the following components: a styrene-acrylic emulsion, alkyd resin, nano silicon dioxide, allylboronic acid pinacol ester, hollow microspheres, hydroxyethyl cellulose, a vinyl-vinyl acetate copolymer, sodium ricinoleate organic modified sepiolite powder, a dispersant, a filler and deionized water. When the heat insulation coating is applied to the building exterior walls, the heat insulation coating is obvious in heat insulation effect, has flame retardance and weather resistance, is low in specific gravity, low in heat conduction coefficient, high in adhesion performance, difficult to fall off and high in toughness; meanwhile, the heat conduction coefficient of the coating is reduced; the light reflectivity of the coating is improved; the heat insulation effect is improved.

Owner:安徽五岳松纳米技术有限公司

Charger shell insulating coating

InactiveCN106336804AThe preparation process is simpleExcellent flame retardantFireproof paintsAntifouling/underwater paintsPolyesterSodium Bentonite

The invention relates to a charger shell insulating coating, which is composed of the following ingredients: acetone, aluminium silicate, polyester acrylic resin, bentonite, potash dibutyl phthalate, maleic anhydride grafted polyethylene, polylactic acid, cottonseed oil, squalane, phosphonitrilic chloride trimer, pyromellitic dianhydride, benzothiazole, calcium propionate, chlorothalonil, isothiazolinone, polyvinyl alcohol, sodium castorate, ethylene glycol monosalicylate, sodium aluminate, ferric trichloride, titanium dioxide powder, tributyl citrate, vinyltriethoxysilane, vancomycin, sodium diacetate, rubber particle, zirconium silicate powder and chloroplatinic acid. The product of the invention has superior flame retardance, acid and alkali resistance and anti-mildew and antibacterial properties. According to the invention, product performance is improved.

Owner:四川利众丰商贸有限公司

Runway material for stadium

InactiveCN106118020AExcellent flame retardantGood acid and alkali resistancePolyesterDehydroacetic acid

Owner:王志英

A kind of synthetic method of stannous ricinoleate

ActiveCN112574025BLow costSimple and fast operationOrganic compound preparationCarboxylic acid salt preparationSodium methoxideHydration reaction

The invention discloses a synthesis method of stannous ricinoleate. The present invention adopts two-step reaction, the first step of reaction takes ricinoleic acid as raw material, uses solvent A, and under certain reaction conditions, reacts with sodium hydroxide, sodium methoxide or sodium methoxide methanol solution to synthesize sodium ricinoleate; the second step Reaction, with sodium ricinoleate as raw material, using solvent B, under heating condition, with anhydrous stannous chloride, hydrated stannous chloride or stannous sulfate reaction synthesis stannous ricinoleate; Wherein, solvent A is alcohol solvent; solvent B is alcohol solvent, aromatic solvent or polar aprotic solvent; both solvent A and solvent B can be recovered by distillation and recycled. The invention has the advantages of low cost of raw materials, simple operation, less discharge of three wastes, and high reaction efficiency.

Owner:SHANGHAI MAIPU NEW MATERIAL TECH CO LTD

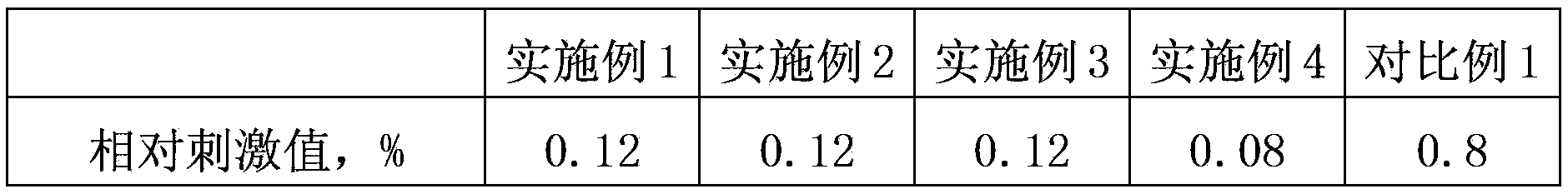

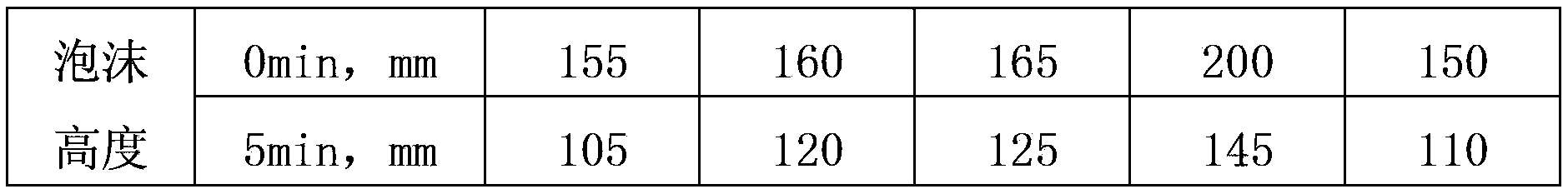

Sanguisorba antibacterial compound soap

ActiveCN103666884BSurface-active non-soap compounds and soap mixture detergentsSkin careSodium ricinoleateIrritation

The invention discloses a sanguisorba antibacterial compound soap, comprising the following raw materials in parts by weight: 0.05-0.15 part of sanguisorba extract, 15-25 parts of sodium cocoate, 50-70 parts of sodium ricinoleate, 3-5 parts of cocamidopropylamine oxide, 3-5 parts of olivamidopropylamine oxide and 20 parts of water. The sanguisorba antibacterial compound soap provided by the invention is fine and smooth and stable in foam, mild in nature, low in irritation to skin, and also capable of effectively killing bacterial after being added with the sanguisorba extract.

Owner:蚌埠启邦科技信息咨询有限公司

Process for producing an Anti-adherent semi-paste compound for liquid steel on solid metal and an Anti-adherent semi-paste compound for liquid steel on solid metal

InactiveUS20160068685A1Efficient use ofOther chemical processesWelding/cutting media/materialsMaterials scienceSodium hydroxide

A process for producing an anti-adherent semi-paste compound for liquid steel on solid metal, as well as an anti-adherent semi-paste compound for liquid steel on solid metal, are disclosed. The semi-paste compound may include a mixture of sodium tripolyphosphate, citric acid, sodium hydroxide, sodium ricinoleate, sodium silicate, benzalkonium chloride, gum, silicone oil, water, isothiazolinone and sulphonic acid. The compound may not include any volatile substances. The compound may be neutralized to a pH of 7.2±0.5.

Owner:DALPIAZ MAYCON ISENSE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com