Runway material for stadium

A technology for sports fields and tracks, which is applied in the field of track materials for sports fields, can solve the problems of incomplete improvement of the rebound rate, tensile strength and elongation at break of plastic tracks, and restrict the performance of plastic tracks, so as to achieve superior flame retardancy , high rebound rate, and the effect of improving product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

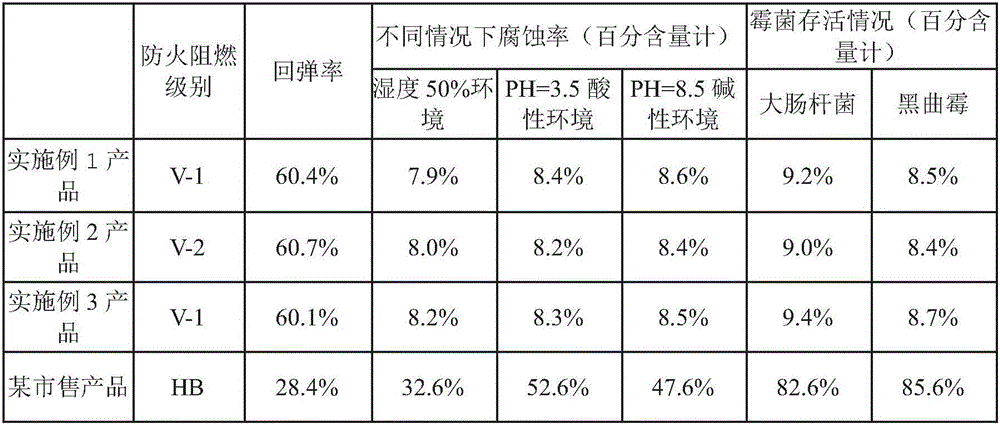

Embodiment 1

[0016] The sports track material used in the present embodiment is composed of the following components in parts by mass: 12 parts of furfuryl alcohol resin, 10 parts of neoprene rubber, 10 parts of metallocene polyethylene, 8 parts of walnut oil, 10 parts of peanut oil, epoxy 10 parts of octyl stearate, 8 parts of polypropylene glycol, 10 parts of polyacrylate emulsion, 10 parts of dehydroacetic acid, 8 parts of urotropine, 8 parts of berberine, 8 parts of calcium sulfite, phenyl hydrogen silicone resin 10 parts, 8 parts of ferrous sulfate, 6 parts of polyester yarn, 10 parts of zinc sulfide, 8 parts of 5-aminobenzimidazolone, 6 parts of white beeswax, 8 parts of glass powder, 6 parts of soybean powder, polybenzimidazolone 6 parts of amine, 8 parts of amidinourea phosphate, 8 parts of sodium bentonite, 8 parts of cellulose acetate butyrate, 8 parts of sodium ricinoleate, 8 parts of lauryl methacrylate, 2,2-dimethylolpropane 8 parts of acid, 8 parts of 2-tert-butylhydroquinone...

Embodiment 2

[0022] The sports track material used in the present embodiment is composed of the following components in parts by mass: 14 parts of furfuryl alcohol resin, 12 parts of neoprene rubber, 12 parts of metallocene polyethylene, 10 parts of walnut oil, 12 parts of peanut oil, epoxy 12 parts of octyl stearate, 10 parts of polypropylene glycol, 12 parts of polyacrylate emulsion, 12 parts of dehydroacetic acid, 10 parts of urotropine, 10 parts of berberine, 10 parts of calcium sulfite, phenyl hydrogen silicone resin 12 parts, 10 parts of ferrous sulfate, 8 parts of polyester yarn, 12 parts of zinc sulfide, 10 parts of 5-aminobenzimidazolone, 8 parts of white beeswax, 10 parts of glass powder, 8 parts of soybean powder, polybenzimidazolone 8 parts of amine, 10 parts of amidinourea phosphate, 10 parts of sodium bentonite, 10 parts of cellulose acetate butyrate, 10 parts of sodium ricinoleate, 10 parts of lauryl methacrylate, 2,2-dimethylolpropane 10 parts of acid, 10 parts of 2-tert-bu...

Embodiment 3

[0028] The sports track material used in the present embodiment is composed of the following components in parts by mass: 16 parts of furfuryl alcohol resin, 14 parts of neoprene rubber, 14 parts of metallocene polyethylene, 12 parts of walnut oil, 14 parts of peanut oil, epoxy 14 parts of octyl stearate, 12 parts of polypropylene glycol, 14 parts of polyacrylate emulsion, 14 parts of dehydroacetic acid, 12 parts of urotropine, 12 parts of berberine, 12 parts of calcium sulfite, phenyl hydrogen silicone resin 14 parts, 12 parts of ferrous sulfate, 10 parts of polyester yarn, 14 parts of zinc sulfide, 12 parts of 5-aminobenzimidazolone, 10 parts of white beeswax, 12 parts of glass powder, 10 parts of soybean powder, polybenzimidazolone 10 parts of amine, 12 parts of amidinourea phosphate, 12 parts of sodium bentonite, 12 parts of cellulose acetate butyrate, 12 parts of sodium ricinoleate, 12 parts of lauryl methacrylate, 2,2-dimethylolpropane 12 parts of acid, 12 parts of 2-ter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com