Multifunctional waterborne additive with wetting and thickening functions, and manufacturing method thereof

A water-based additive and multi-functional technology, applied in the direction of coating, etc., can solve the problems of high cost of water-based products, interference with other performances, and influence on system stability, etc., to achieve the effect of reducing the batching process, reducing the cost of use, and avoiding mutual interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

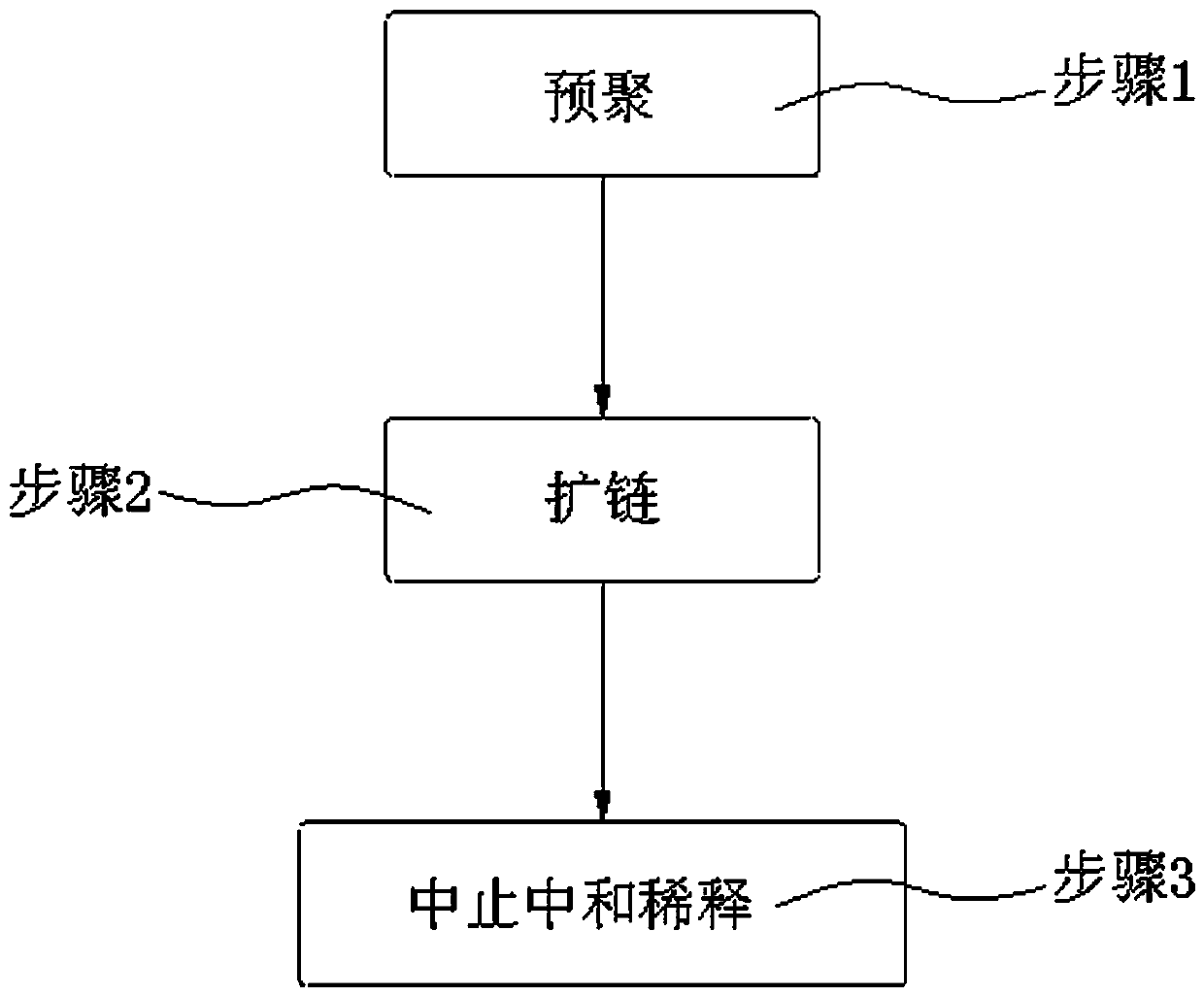

Method used

Image

Examples

Embodiment 1

[0034] Diisocyanate HDI 98.8g, nonionic wetting agent propylene oxide ethylene oxide copolymer (polyoxypropylene oxide ethylene copolymer) F38 200g, 80 0 C, add 22.2g of diisocyanate IPDI to react for 1 hour, then add 100g of hydroxyl silicone oil SF-8427, and then react for 3 hours to measure the NCO value, and react until the NCO value is below 2.8mmol / g to obtain a prepolymer; add dimethylol to the prepolymer Propionic acid DMPA 13.4g reacted for 1 hour, then began to drop chain extender diol BDO 20-44.9g (depending on the viscosity) until the viscosity reached 10000-30000mPa.s / 25 0 C semi-finished product, alcohol ether solvent PMA 100g semi-finished product, add 32g sodium ricinoleate and react for 2 hours until NCO is 0, add triethanolamine TEA 11.3g, add the product to alcohol ether solvent PMA 600g and disperse at high speed for 20 minutes to obtain the finished product, the viscosity of the finished product Up to 20000mpa.s, thickening wetting agent with 42% non-volat...

Embodiment 2

[0036] Alcohol ether solvent PMA 400g, diisocyanate HDI 98.8g, non-ionic wetting agent propylene oxide ethylene oxide copolymer (polyoxypropylene oxide ethylene copolymer) F38 100g, polyol PEG2000 100g80 0 C reacted for 1 hour, then added 22.2g of diisocyanate IPDI, 100g of hydroxyl silicone oil SF-8427 and reacted for 3 hours to measure the NCO value below 2.8mmol / g to obtain a prepolymer; add dimethylol propionic acid DMPA13 to the prepolymer .4g was reacted for 1 hour, then began to drop chain extender diol BDO 20-44.9g (depending on the viscosity) until the viscosity reached 10000-30000mPa.s / 25 0 C to get a semi-finished product, add 32g of sodium ricinoleate and react for 2 hours until the NCO is 0, add 13g of triethanolamine TEA, 100g of PMA, disperse at high speed for 30 minutes to get a finished product, the viscosity of the finished product can reach 20000mPa.s / 25 0 C, 50% non-volatile matter. Adding 1% to water-based polyurethane resin can reduce the surface tension...

Embodiment 3

[0038] Alcohol ether solvent PMA 300g, diisocyanate HDI42g, non-ionic wetting agent propylene oxide ethylene oxide copolymer (polyoxypropylene oxide ethylene copolymer) F38 150g, 80 0 Add 22.2g of diisocyanate IPDI and 150g of hydroxyl silicone oil SF-8427 for 1 hour of reaction in C, and then react for 3 hours to measure the NCO value below 0.74mmol / g to obtain a prepolymer; add 13.4g of dimethylol propionic acid DMPA to the prepolymer React for 1 hour, then start to drop chain extender diol BDO 6-13g (depending on the viscosity) until the viscosity reaches 20000-30000mPa.s / 25 0 C to obtain a semi-finished product, add 32g of sodium ricinoleate and react for 2 hours until the NCO is 0, then add 13g of triethanolamine TEA and disperse at high speed for 30 minutes to obtain a finished product. s / 25 0 C, 63% non-volatile matter. Adding 1-3% to water-based polyurethane resin can make the viscosity reach 500mPa.s / 25 0 Above C, the surface tension coefficient is below 28mN / m, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com