Charger shell insulating coating

An insulating coating and charger technology, applied in coatings, organic insulators, organic liquid insulators, etc., can solve problems such as large power devices, and achieve the effects of improving product performance, simple preparation process, and anti-mildew and antibacterial properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

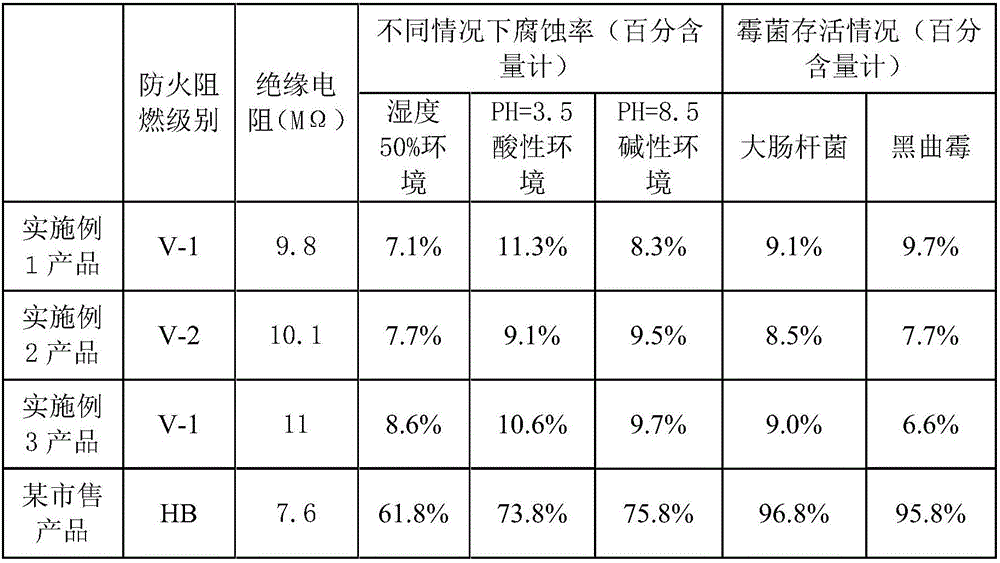

Examples

Embodiment 1

[0016] The insulating coating of the charger shell in the present embodiment is composed of the following components in parts by mass: 16 parts of acetone, 18 parts of aluminum silicate, 14 parts of polyester acrylic resin, 12 parts of bentonite, potassium carbonate diphthalate 18 parts of butyl ester, 14 parts of maleic anhydride grafted polyethylene, 12 parts of polylactic acid, 18 parts of cottonseed oil, 14 parts of squalane, 12 parts of hexachlorocyclotriphosphazene, 18 parts of pyromellitic anhydride, benzo 14 parts of thiazole, 14 parts of calcium propionate, 12 parts of chlorothalonil, 18 parts of isothiazolone, 14 parts of polyvinyl alcohol, 12 parts of sodium ricinoleate, 18 parts of ethylene glycol salicylate, 14 parts of sodium aluminate 12 parts of iron trichloride, 18 parts of titanium dioxide powder, 14 parts of tributyl citrate, 12 parts of vinyltriethoxysilane, 18 parts of vancomycin, 14 parts of sodium diacetate, 14 parts of rubber particles, zirconium Britis...

Embodiment 2

[0022] The insulating coating of the charger shell in the present embodiment is composed of the following components in parts by mass: 18 parts of acetone, 20 parts of aluminum silicate, 16 parts of polyester acrylic resin, 14 parts of bentonite, potassium carbonate diphthalate 20 parts of butyl ester, 16 parts of maleic anhydride grafted polyethylene, 14 parts of polylactic acid, 20 parts of cottonseed oil, 16 parts of squalane, 14 parts of hexachlorocyclotriphosphazene, 20 parts of pyromellitic anhydride, benzo 16 parts of thiazole, 16 parts of calcium propionate, 14 parts of chlorothalonil, 20 parts of isothiazolone, 16 parts of polyvinyl alcohol, 14 parts of sodium ricinoleate, 20 parts of ethylene glycol salicylate, 16 parts of sodium aluminate 14 parts of iron trichloride, 20 parts of titanium dioxide powder, 16 parts of tributyl citrate, 14 parts of vinyltriethoxysilane, 20 parts of vancomycin, 16 parts of sodium diacetate, 16 parts of rubber particles, zirconium Englis...

Embodiment 3

[0028] The insulating coating of the charger shell in the present embodiment is composed of the following components in parts by mass: 20 parts of acetone, 22 parts of aluminum silicate, 18 parts of polyester acrylic resin, 16 parts of bentonite, potassium carbonate diphthalate 22 parts of butyl ester, 18 parts of maleic anhydride grafted polyethylene, 16 parts of polylactic acid, 22 parts of cottonseed oil, 18 parts of squalane, 16 parts of hexachlorocyclotriphosphazene, 22 parts of pyromellitic anhydride, benzo 18 parts of thiazole, 18 parts of calcium propionate, 16 parts of chlorothalonil, 22 parts of isothiazolone, 18 parts of polyvinyl alcohol, 16 parts of sodium ricinoleate, 22 parts of ethylene glycol salicylate, 18 parts of sodium aluminate 16 parts of iron trichloride, 22 parts of titanium dioxide powder, 18 parts of tributyl citrate, 16 parts of vinyltriethoxysilane, 22 parts of vancomycin, 18 parts of sodium diacetate, 18 parts of rubber particles, zirconium Britis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com