Sodium ricinoleate organic modified sodium-based montmorillonite and application thereof in hard polyurethane

A technology of ricinoleic acid sodium salt and sodium-based montmorillonite, which is applied in the field of organically modified montmorillonite and polyurethane, and can solve the problems of increased layer spacing of modified montmorillonite and easy decomposition at high temperature. Achieve the effect of rich content, good dispersion and high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

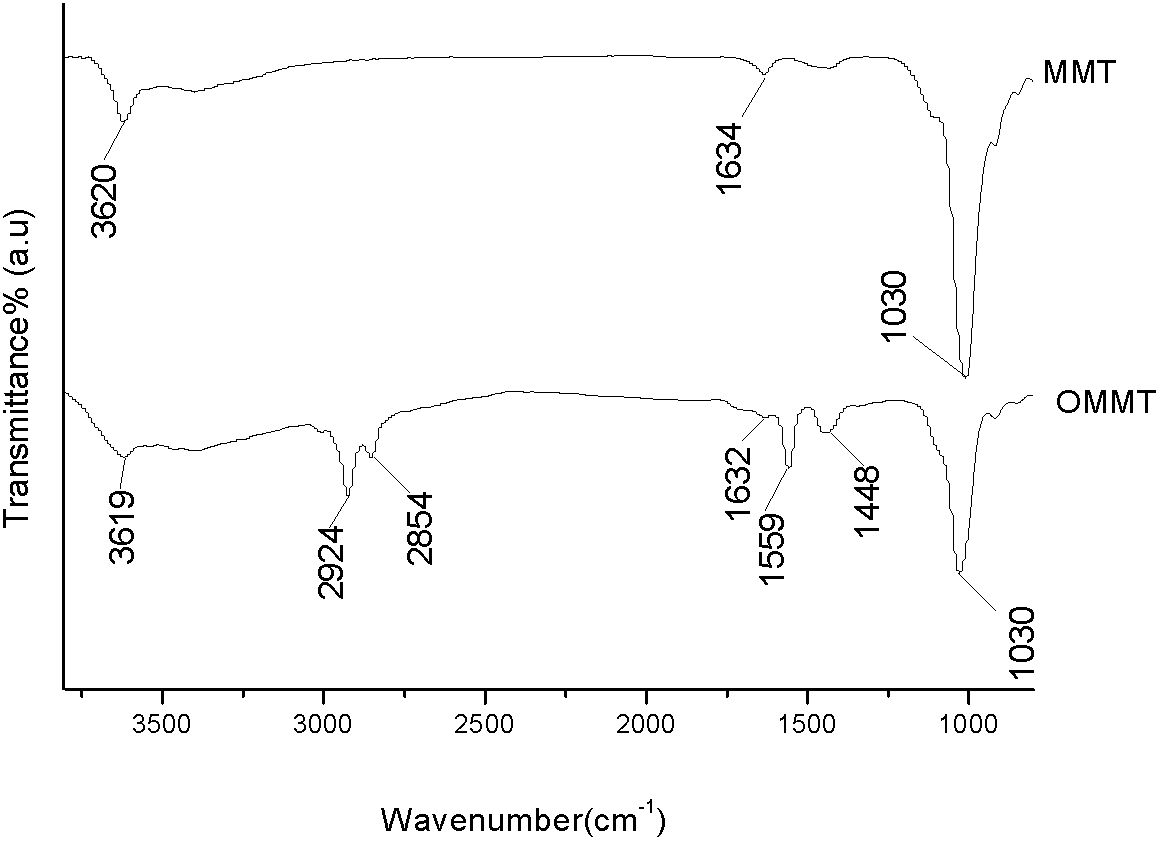

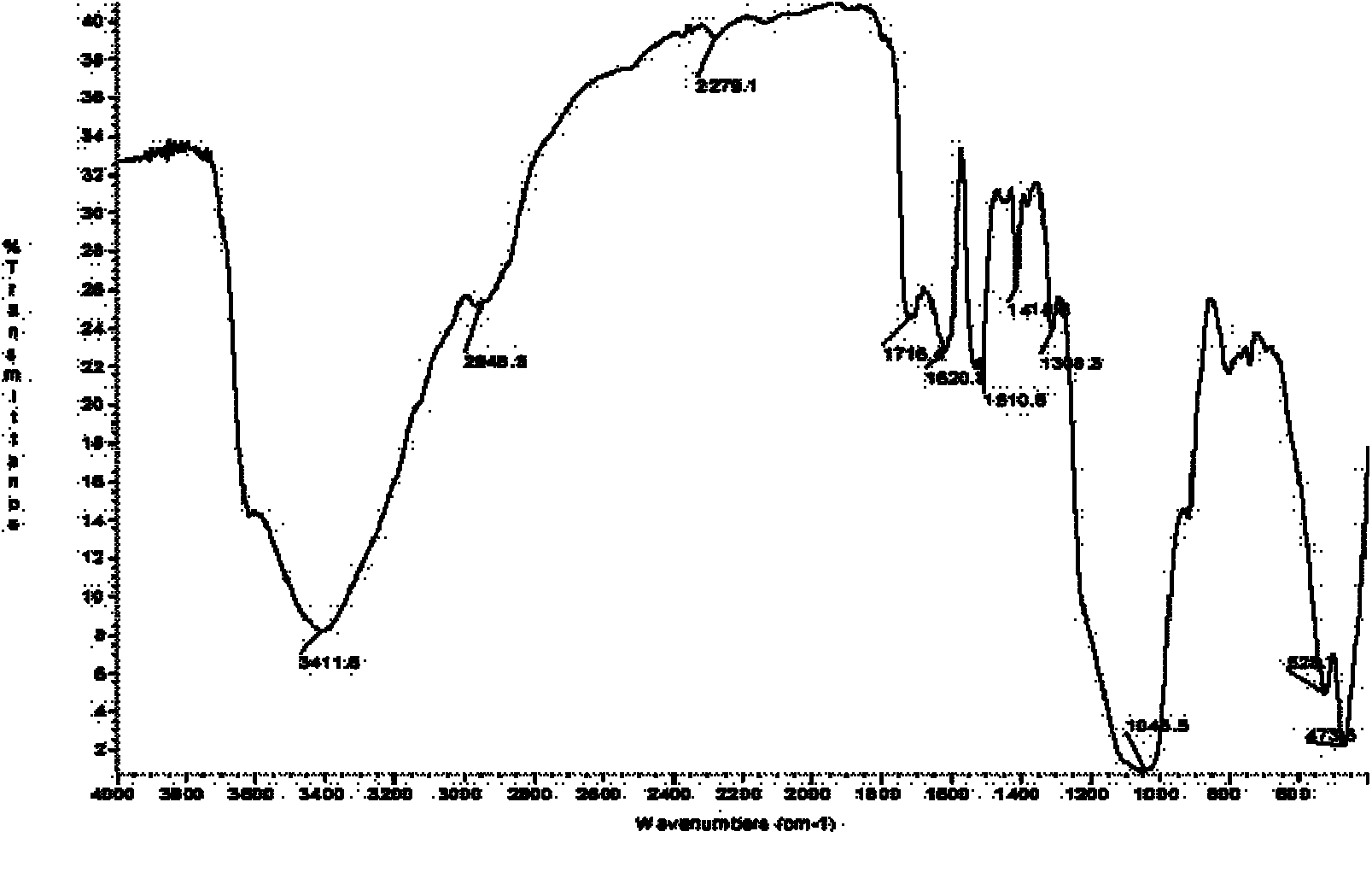

[0022] Example 1. Add sodium-based montmorillonite to the flask, configure 5%wt soil slurry solution, adjust pH to 5.5, emulsify at 50-60°C for 3h, add ricinoleic acid sodium salt 0.5CEC, stir at 50-60°C for 3h, 900~1000r / min, centrifuge while hot, wash with water until the pH of the supernatant is 7, dry, grind, and pass through a 200-mesh sieve to obtain organically modified montmorillonite of ricinoleic acid sodium salt. The modified montmorillonite layer spacing (d 001 ) is 1.38nm. Then, according to the preparation formula of rigid polyurethane foam in Table 1, the combined polyol was obtained, dispersed evenly by ultrasonic, then mixed with isocyanate and stirred at high speed for 20-30 s at a speed of 3000-3500 r / min, poured into the mold, and aged for 48 h.

Embodiment 2

[0023] Example 2. Add sodium-based montmorillonite to the flask, configure a 5%wt soil slurry solution, adjust the pH to 5.5, emulsify at 50-60°C for 3h, add ricinoleic acid sodium salt 1CEC, stir at 50-60°C for 3h, and rotate at 900°C ~1000r / min, centrifuge while hot, wash with water until the pH of the supernatant is 7, dry, grind, and pass through a 200-mesh sieve to obtain the organically modified montmorillonite of ricinoleic acid sodium salt, and the layer of the modified montmorillonite Spacing (d 001 ) is 4.58nm. Then, according to the preparation formula of rigid polyurethane foam in Table 1, the combined polyol was obtained, dispersed evenly by ultrasonic, then mixed with isocyanate and stirred at high speed for 20-30 s at a speed of 3000-3500 r / min, poured into the mold, and aged for 48 hours.

Embodiment 3

[0024] Example 3. Add sodium-based montmorillonite to the flask, prepare a 5%wt soil slurry solution, adjust the pH to 5.5, emulsify at 50-60°C for 3h, add ricinoleic acid sodium salt 2CEC, stir at 50-60°C for 3h, and rotate at 900°C ~1000r / min, centrifuge while hot, wash with water until the pH of the supernatant is 7, dry, grind, and pass through a 200-mesh sieve to obtain the organically modified montmorillonite of ricinoleic acid sodium salt, and the layer of the modified montmorillonite Spacing (d 001 ) is 4.63nm. Then, according to the preparation formula of rigid polyurethane foam in Table 1, the combined polyol was obtained, dispersed evenly by ultrasonic, then mixed with isocyanate and stirred at high speed for 20-30 s at a speed of 3000-3500 r / min, poured into the mold, and aged for 48 h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com