Preparation method of nano calcium carbonate reinforced and toughened PVC

A nano-calcium carbonate and toughening technology, which is applied in the field of preparation of nano-calcium carbonate-strengthened and toughened PVC, can solve the problem of performance reduction such as toughness, strength and rigidity, failure to achieve satisfactory filling and reinforcing effects, and high polymer compatibility. Insufficient and other problems, to achieve the effect of improving rheological properties, volume reduction, and specific surface area increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

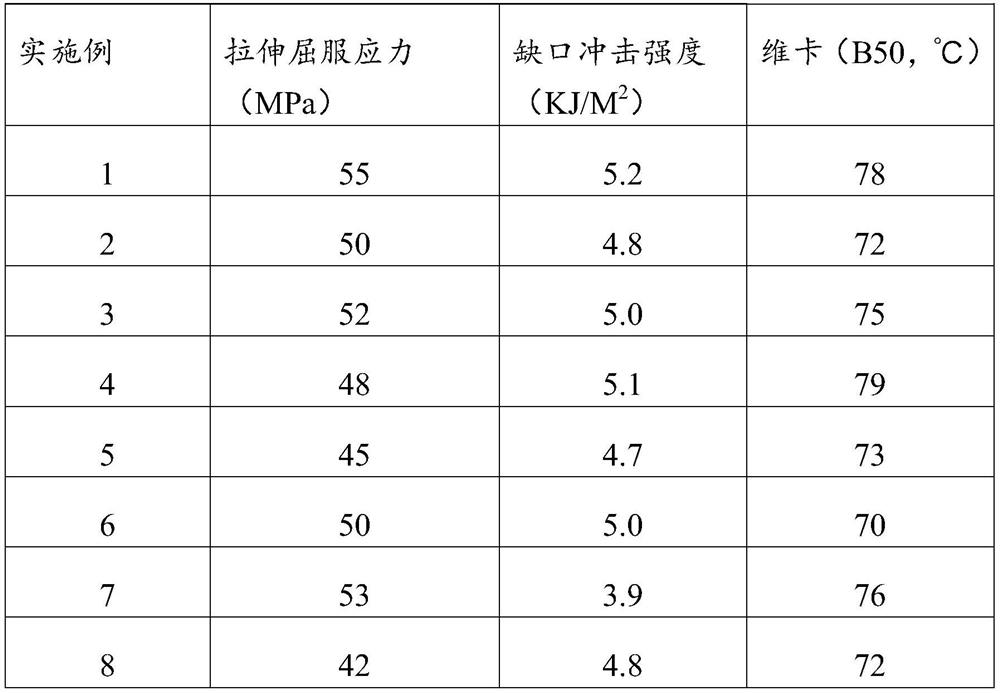

Examples

Embodiment 1

[0025] A preparation method for nano-calcium carbonate stiffened and toughened PVC, comprising the following steps:

[0026] (1) Sodium ricinoleic acid ester sulfate was dissolved in water and ultrasonically oscillated at room temperature for 8 minutes to obtain solution A; methyltriethoxysilane was dissolved in ethanol solution and ultrasonically oscillated at room temperature for 15 minutes to obtain solution B; 100rpm;

[0027] (2) Add ammonia water to solution B under stirring, ultrasonically shake at 60°C for 15 minutes, then add diethanolamine, continue ultrasonication for 25 minutes, and mix with solution A to obtain a surface treatment agent. The mass ratio of solution A to solution B is 10:1, the mass ratio of solution B, alkali and diethanolamine is 5:0.1:1;

[0028] (3) adding the surface treatment agent to the nano-calcium carbonate suspension, heating to 55° C., reacting for 6 hours, and then washing and drying to obtain a modified nano-calcium carbonate; wherein...

Embodiment 2

[0031] A preparation method for nano-calcium carbonate stiffened and toughened PVC, comprising the following steps:

[0032] (1) Sodium ricinoleic acid ester sulfate was dissolved in water and ultrasonically oscillated at room temperature for 5 minutes to obtain solution A; methyltriethoxysilane was dissolved in ethanol solution and ultrasonically oscillated at room temperature for 10 minutes to obtain solution B; 100rpm;

[0033] (2) Add ammonia water to solution B under stirring, ultrasonically shake at 50°C for 15 minutes, then add diethanolamine, continue ultrasonication for 25 minutes, and mix with solution A to obtain a surface treatment agent. The mass ratio of solution A to solution B is 10:0.1; the mass ratio of solution B, alkali and diethanolamine is 5:0.05:0.5;

[0034] (3) adding the surface treatment agent to the nano-calcium carbonate suspension, heating to 45° C., reacting for 8 hours, and then washing and drying to obtain a modified nano-calcium carbonate; wh...

Embodiment 3

[0037] A preparation method for nano-calcium carbonate stiffened and toughened PVC, comprising the following steps:

[0038] (1) Sodium ricinoleic acid ester sulfate was dissolved in water and ultrasonically oscillated at room temperature for 10 minutes to obtain solution A; methyltriethoxysilane was dissolved in ethanol solution and ultrasonically oscillated at room temperature for 20 minutes to obtain solution B; 100rpm;

[0039] (2) Add ammonia water to solution B under stirring, ultrasonically shake at 65°C for 15 minutes, then add diethanolamine, continue ultrasonication for 35 minutes, and mix with solution A to obtain a surface treatment agent. The mass ratio of solution A to solution B is 10:2; the mass ratio of solution B, alkali and diethanolamine is 5:0.2:2;

[0040] (3) adding the surface treatment agent to the nano-calcium carbonate suspension, heating to 65° C., reacting for 5 hours, and then washing and drying to obtain a modified nano-calcium carbonate; wherei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com