Multiple-efficiency water purification ceramic material as well as preparation method and application thereof

A ceramic material and multi-functional technology, which is applied in the field of multi-functional water purification ceramic materials and its preparation, can solve the problems of unsatisfactory functional effects and uneven product quality, and achieve enhanced functions, enhanced antibacterial functions, and good economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

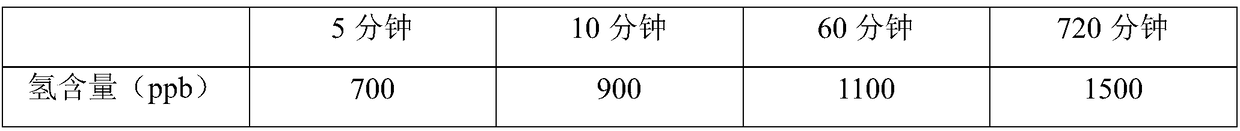

Examples

Embodiment 1

[0069] The multifunctional water purification ceramic material is made of the following raw materials in parts by weight:

[0070] 40 parts of substrate components, 30 parts of hydrogen-rich components, 3.5 parts of antibacterial components and 7 parts of binder;

[0071] The base material component is made of raw materials in the following weight percentages:

[0072] 30% tourmaline, 20% hydronite, 30% medical stone, 10% calcium oxide and 10% zeolite.

[0073] The hydrogen-rich component is made of raw materials in the following weight percentages:

[0074] Metal magnesium powder 40%, magnesium oxide powder 40%, KDF alloy powder 10% and three-dimensional graphene 10%.

[0075] Described antibacterial component is made of the raw material of following percentage by weight:

[0076] 25% of far-infrared ceramic powder, 25% of nano-zinc oxide, 40% of titanium oxide and 10% of nano-zirconia.

[0077] Described binding agent is made by the raw material of following percentage b...

Embodiment 2

[0091] The multifunctional water purification ceramic material is made of the following raw materials in parts by weight:

[0092] 30 parts of substrate components, 20 parts of hydrogen-rich components, 2 parts of antibacterial components and 3 parts of binders;

[0093] The base material component is made of raw materials in the following weight percentages:

[0094] 20% tourmaline, 25% hydronite, 20% medical stone, 20% calcium oxide and 15% zeolite.

[0095] The hydrogen-rich component is made of raw materials in the following weight percentages:

[0096]Metal magnesium powder 20%, magnesium oxide powder 60%, KDF alloy powder 10% and three-dimensional graphene 10%.

[0097] Described antibacterial component is made of the raw material of following percentage by weight:

[0098] 30% of far-infrared ceramic powder, 20% of nano-zinc oxide, 45% of titanium oxide and 5% of nano-zirconia.

[0099] Described binding agent is made by the raw material of following percentage by w...

Embodiment 3

[0113] The multifunctional water purification ceramic material is made of the following raw materials in parts by weight:

[0114] 50 parts of substrate components, 25 parts of hydrogen-rich components, 5 parts of antibacterial components and 10 parts of adhesive;

[0115] The base material component is made of raw materials in the following weight percentages:

[0116] 20% tourmaline, 10% hydronite, 25% medical stone, 25% calcium oxide and 20% zeolite.

[0117] The hydrogen-rich component is made of raw materials in the following weight percentages:

[0118] Metal magnesium powder 60%, magnesium oxide powder 20%, KDF alloy powder 10% and three-dimensional graphene 10%.

[0119] Described antibacterial component is made of the raw material of following percentage by weight:

[0120] 20% far-infrared ceramic powder, 30% nano zinc oxide, 45% titanium oxide and 5% nano zirconium dioxide.

[0121] Described binding agent is made by the raw material of following percentage by w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com