Addition face fake composite silicon rubber and preparation method thereof

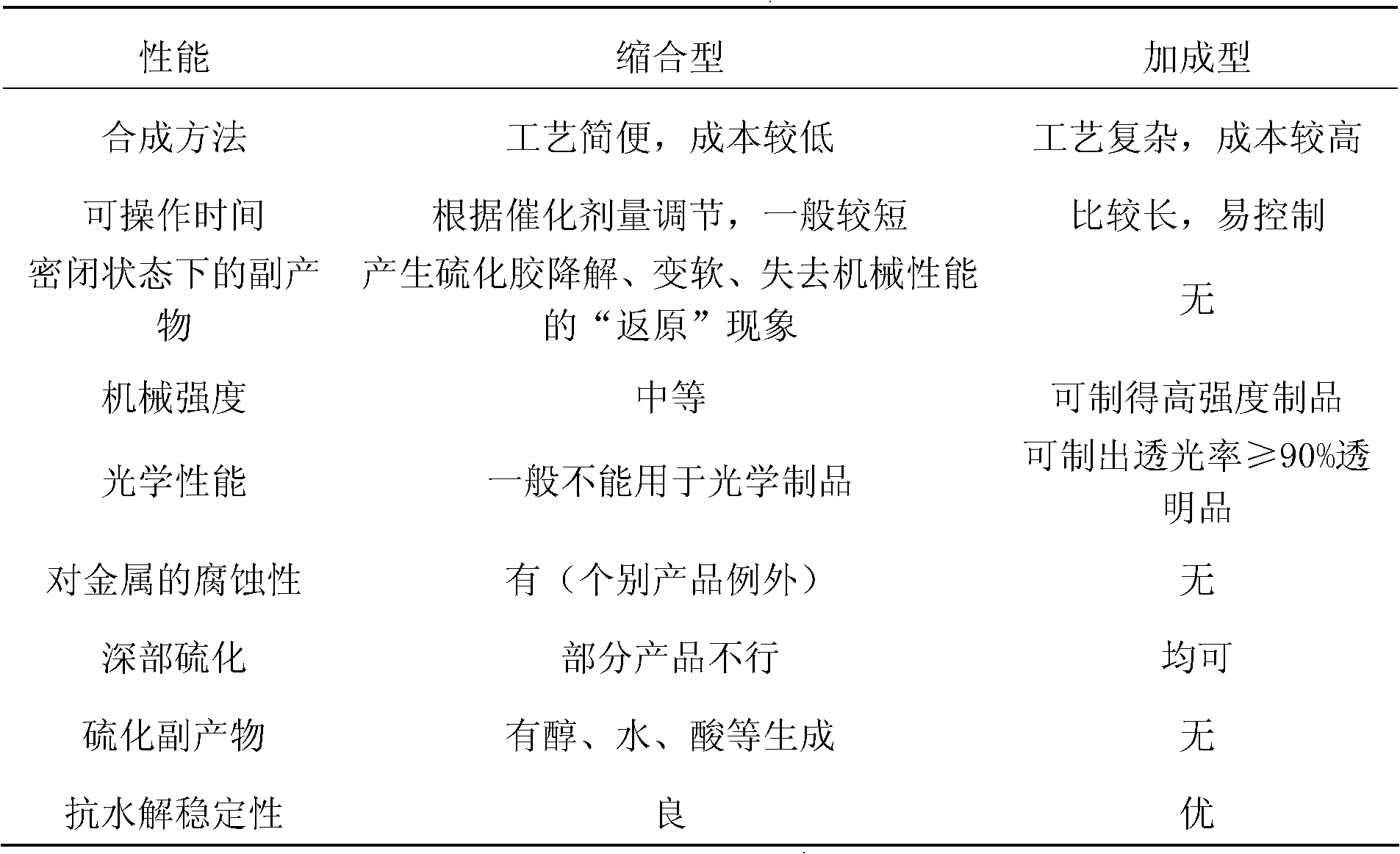

An addition-type, silicone rubber technology, applied in the field of addition-type facial prosthetic silicone rubber and its preparation, can solve the problems of difficulty in meeting the urgent needs of patients, insufficient water absorption and solubility, and backwardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

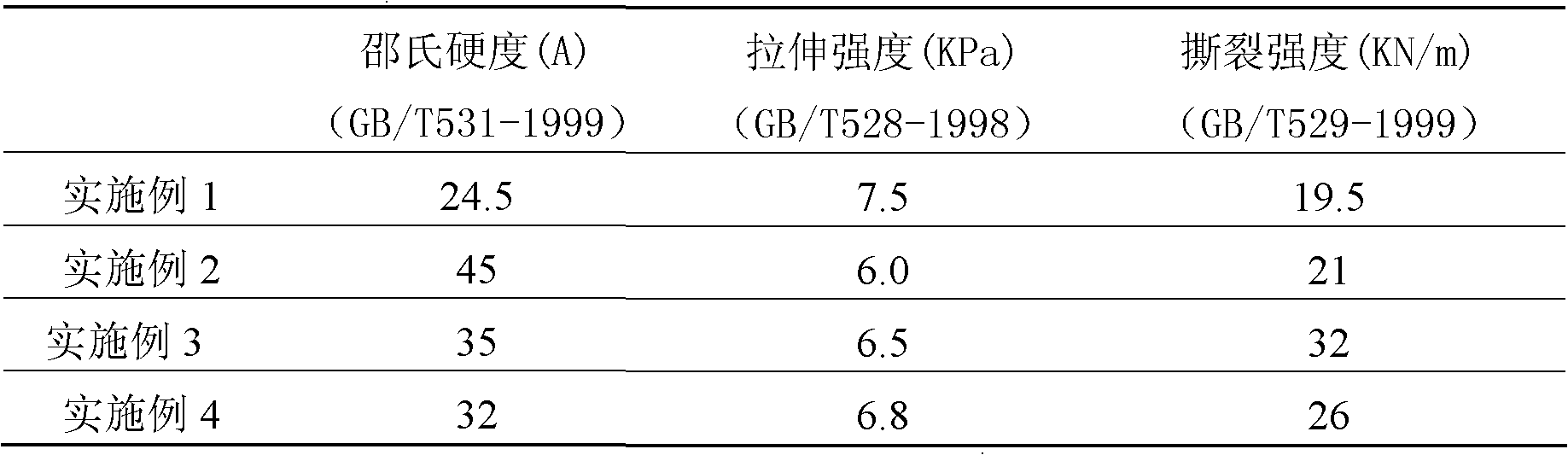

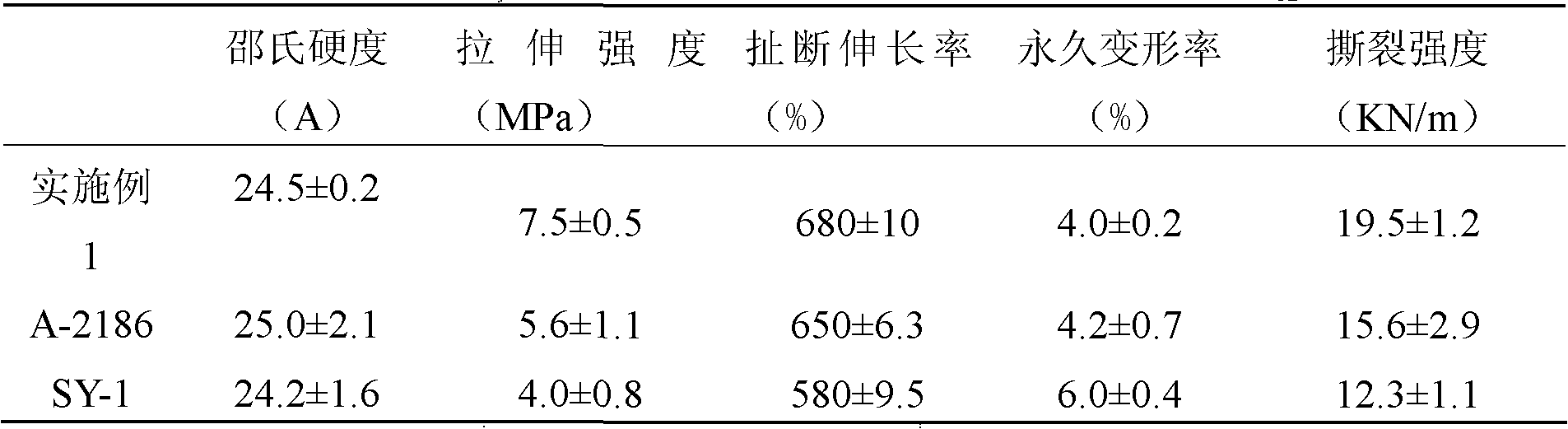

Examples

Embodiment 1

[0034] According to the base polymer (i.e. vinyl silicone oil) 80wt%; filler 15wt%; crosslinking agent, catalyst and polymerization inhibitor and 5wt% of the preparation of addition type facial prosthetic silicone rubber:

[0035] Preparation of vinyl silicone oil: First, take 75.2 parts by weight of chemically pure octamethylcyclotetrasiloxane and add it into the reactor, raise the temperature to 90°C, and under stirring at less than 0.01Mpa, blow nitrogen into the ring body for 120min to remove the Stop the nitrogen flow after moisture, then add 2.4 parts by weight of chemically pure divinyltetramethyldisiloxane and stir evenly, then add 2.4 parts by weight of analytically pure tetramethylammonium hydroxide, and heat up under stirring React at 100-110°C until the viscosity of the system remains roughly constant (at 1400±10% mm2 / s), stop stirring, and raise the temperature to 150°C at a rate of 5°C / min under normal pressure for 1 hour to destroy tetramethyl base amine hydroxi...

Embodiment 2

[0038] According to 20wt% of base polymer; 75wt% of filler; 5wt% of the sum of crosslinking agent catalyst and polymerization inhibitor to prepare addition-type facial prosthetic silicone rubber:

[0039] Preparation of vinyl silicone oil: First, take 18.8 parts by weight of octamethylcyclotetrasiloxane and add it into the reactor, raise the temperature to 50°C, and pass nitrogen gas at less than 0.01Mpa under stirring for 30 minutes to remove the nitrogen in the ring body. Stop the nitrogen flow after moisture, then add 0.6 parts by weight of divinyltetramethyldisiloxane and stir evenly, then add 0.6 parts by weight of analytically pure tetramethylammonium hydroxide, and heat up to React at 100-110°C until the viscosity of the system remains roughly constant (3700±10%mm2 / s), then raise the temperature to 150°C at a rate of 5°C / min under normal pressure and react for 1 hour to destroy tetramethylammonium hydroxide , and then gradually heated up to 200°C under stirring, and the...

Embodiment 3

[0042] According to 55wt% of base polymer; 30wt% of filler; 15wt% of the sum of crosslinking agent, catalyst and polymerization inhibitor to prepare addition-type facial prosthetic silicone rubber:

[0043] Preparation of vinyl silicone oil: first, take 51.7 parts by weight of a mixture composed of hexamethylcyclotrisiloxane, octamethylcyclotetrasiloxane and decamethylcyclopentasiloxane and add it to the reactor, and heat up to 95°C, under stirring at less than 0.01Mpa, pass nitrogen gas for 100min to remove moisture in the ring body, stop nitrogen flow, then add 1.65 parts by weight of divinyltetramethyldisiloxane to it and stir evenly, Then add 1.65 parts by weight of analytically pure tetramethylammonium hydroxide, and heat up to 100-110°C for reaction under stirring until the viscosity of the system (21500 ± 10% mm2 / s) is constant. / min heating rate to 150°C for 1 hour to destroy tetramethylammonium hydroxide, then gradually raise the temperature to 200°C under stirring, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com