One-time deep dyeing method for cotton fiber employing indigo dye

A technology of indigo dye and cotton fiber, which is applied in the field of dyeing cotton fiber with indigo dye, which can solve the problems of difficulty in dyeing dark colors at one time, low production efficiency, and complicated dyeing process, so as to improve indigo dyeing rate and reduce processing Cost, effect of improving dyeing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

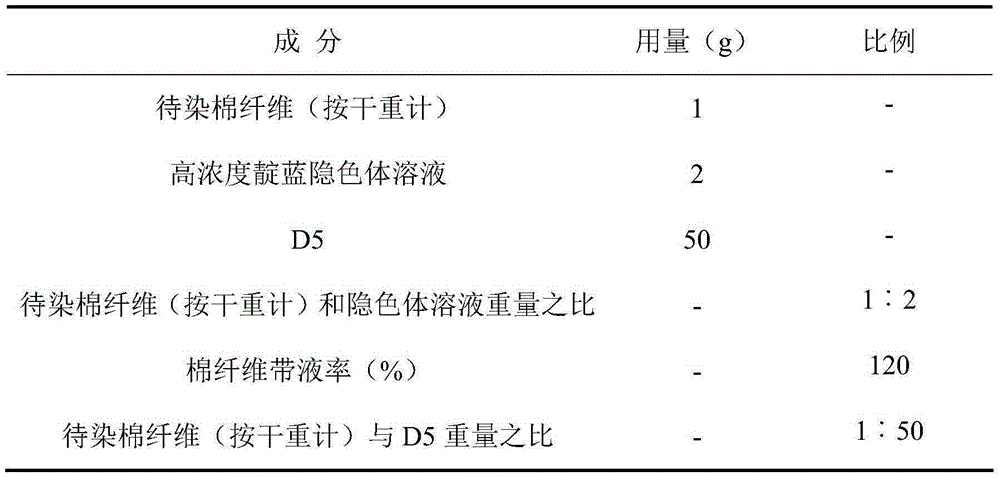

[0024] A kind of indigo dye of cotton fiber once dyes dark color method, comprises the steps:

[0025] (1) Pretreatment of cotton fiber: Weigh 1g of cotton fiber, put it into a caustic soda solution with a concentration of 30g / L, the bath ratio is 1:50, and scour the cotton fiber for 60min at a temperature of 80°C. Then washing and dehydration, control the liquid-carrying rate of cotton fiber to 120%, prepare for dyeing;

[0026] (2) Preparation of high-concentration leuco indigo solution:

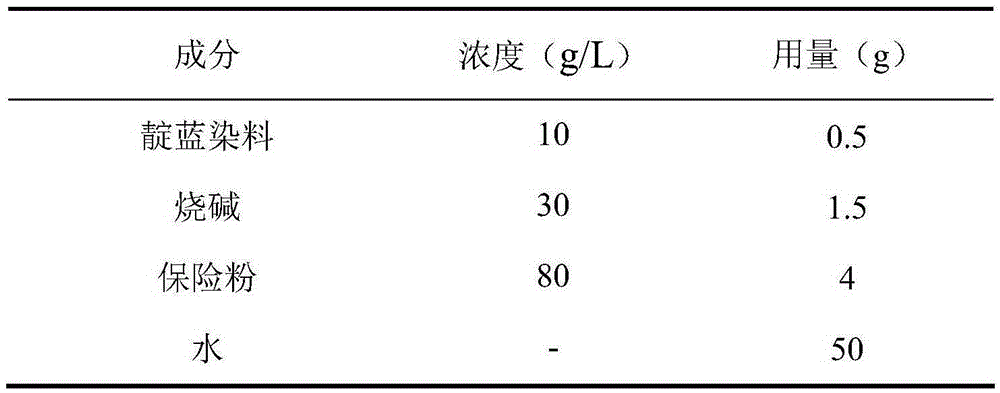

[0027] Table 1 prepares the formula of high concentration (10g / L) leucoindigo solution

[0028]

[0029] Accurately weigh each drug according to the formula in Table 1. Add 1.5g of caustic soda and 4g of sodium hydrosulfite into 50ml of water, stir to dissolve to obtain a reducing solution, then add 0.5g of indigo dye to the prepared reducing solution, and perform reduction in a constant temperature water bath. The reduction conditions are: reduce at 50°C for 30 minutes to prepare a ...

Embodiment 2

[0037] The difference from Example 1 is that the preparation conditions of high-concentration leuco indigo and the dyeing conditions of cotton fibers are different. Other conditions are the same as in Example 1.

[0038] The preparation formula and reduction conditions of high-concentration leuco indigo are shown in Table 3.

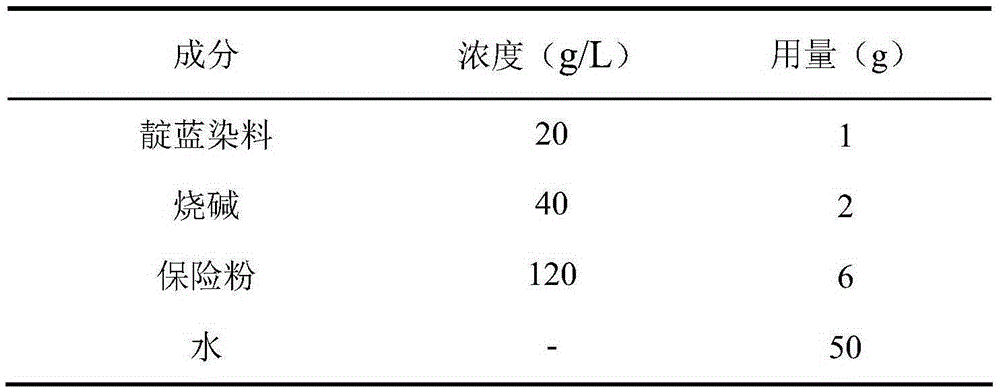

[0039] Table 3 prepares the formula of high concentration (20g / L) leucoindigo solution

[0040]

[0041] The reduction condition is: reduce at 60°C for 20 minutes to prepare a high-concentration (20g / L) leuco indigo solution.

[0042] The dyeing conditions of cotton fiber are as follows: dyeing at room temperature first, heating up to 80°C within 15 minutes, and keeping warm at 80°C for 20 minutes.

Embodiment 3

[0044] The difference from Example 1 is that the preparation conditions of high-concentration leuco indigo and the dyeing conditions of cotton fibers are different. Other conditions are the same as in Example 1.

[0045] The preparation formula and reduction conditions of high-concentration leuco indigo are shown in Table 4.

[0046] Table 4 prepares the formula of high concentration (40g / L) indigo leucosome solution

[0047]

[0048] The reduction condition is: reduce at 55°C for 40 minutes to prepare a high-concentration (40g / L) leuco indigo solution.

[0049] The dyeing conditions of cotton fiber are as follows: dyeing at room temperature first, heating up to 60°C within 10 minutes, and keeping warm at 60°C for 60 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com