High-settling-resistant and high-color depth pigment nanocapsule coating as well as preparation method and application

A nanocapsule and sedimentation technology, applied in the field of pigment capsule coatings, can solve problems such as the difficulty in ensuring color depth and brightness, the inability to prepare fine emulsion polymerization, and the difficulty in making dark-colored fabrics, achieving high pigment coating efficiency, Effect of improving settlement resistance and reducing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

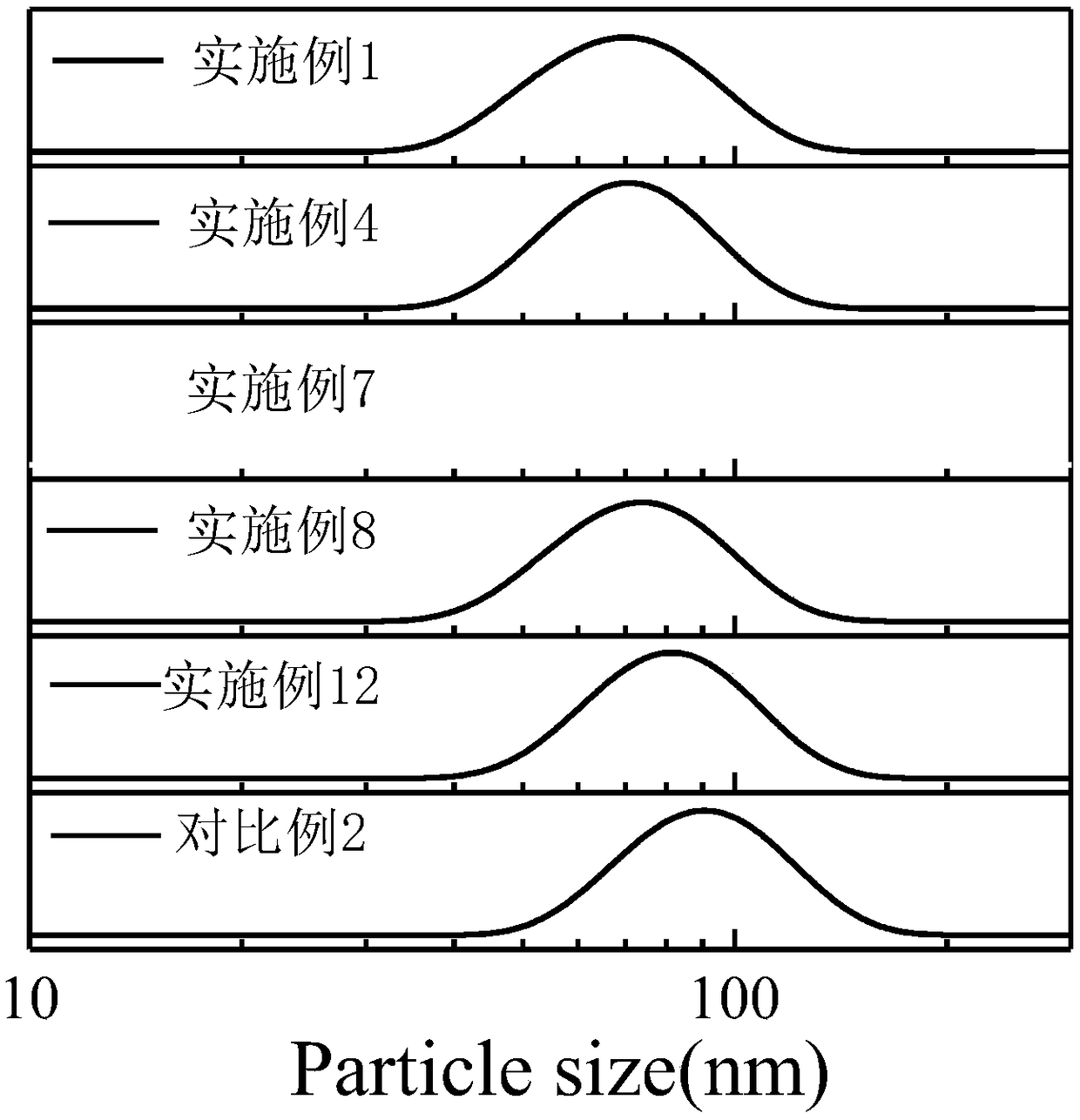

Embodiment 1~15

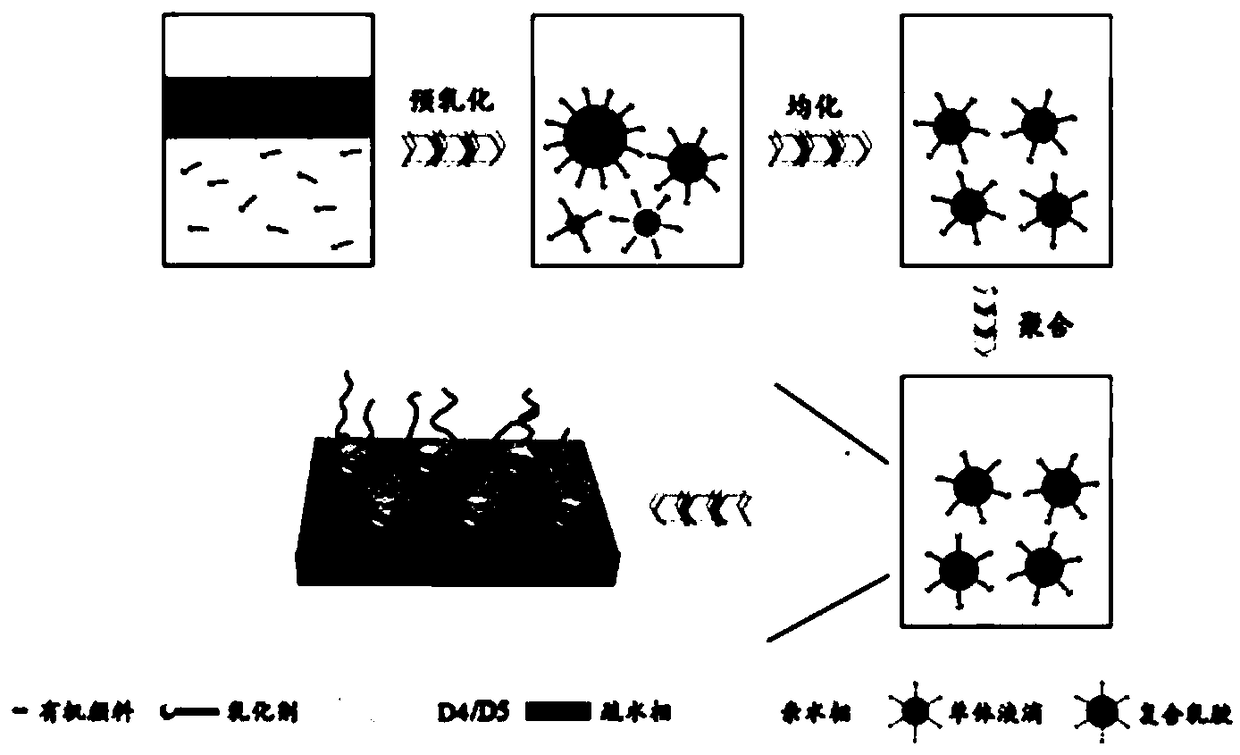

[0060] Step 1: Stir and mix a certain amount of D4 or D5 with organic pigments (Pigment) and acrylic monomers (Acr) according to the formula in Table 1, and obtain an oil phase mixture after ultrasonication, which is used as phase A.

[0061] Step 2: According to the formula in Table 2, add the three emulsifiers into the aqueous solution until completely dissolved, as phase B.

[0062] Step 3: Mix phase A and phase B, and homogenize it by ultrasonic to obtain a miniemulsion; then transfer the miniemulsion to the reaction device, and carry out miniemulsion polymerization under the protection of nitrogen and the action of the initiator dibenzoyl peroxide reaction to obtain a pigment nanocapsule coating with high anti-sedimentation and high color depth.

[0063] Step 4: Take 20g of the prepared nanocapsule emulsion and 0.5g thickener PTF (anionic thickener, its viscosity is 40cps~50cps, pH value is 4.5, solid content is 23%) and mix evenly, add water and stir to adjust to a certa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com