Surface treatment method for nanometer calcium carbonate applied to fill silicone sealant

A nano-calcium carbonate, silicone sealant technology, applied in inorganic pigment treatment, chemical instruments and methods, dyed low molecular organic compound treatment and other directions, can solve the problems of unstable finished product performance, short storage period, etc. , The effect of improving adhesion and storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

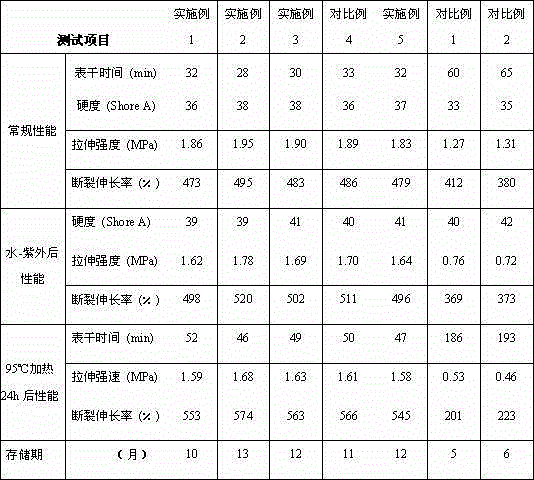

Examples

Embodiment 1

[0033] A kind of surface treatment method that is applied to the nano-calcium carbonate of filling silicone sealant, comprises the following steps:

[0034] (1) Set the specific surface to 30m 2 / g of nano-calcium carbonate slurry is added to the reactor, stirred, and heated to 75°C to obtain nano-calcium carbonate suspension slurry;

[0035] (2) Slowly add a composite surface treatment agent composed of stearic acid and coconut oil to the nano-calcium carbonate suspension under stirring for a surface treatment. The amount added is 3.0% of the dry mass of calcium carbonate, and continue stirring for 15 minutes. Obtain the preliminary modified solution of nano-calcium carbonate;

[0036] The preparation method of the above-mentioned compound surface treatment agent: add stearic acid and coconut oil to the reaction kettle with a mass ratio of 3:1, then add sodium hydroxide with 15% stearic acid mass, and control it at 80°C for saponification reaction to obtain a compound surfa...

Embodiment 2

[0041] A kind of surface treatment method that is applied to the nano-calcium carbonate of filling silicone sealant, comprises the following steps:

[0042] (1) Set the specific surface to 23m 2 / g of nano-calcium carbonate slurry was added to the reactor, stirred, and heated to 60°C to obtain nano-calcium carbonate suspension slurry;

[0043] (2) Slowly add a composite surface treatment agent composed of palmitic acid and coconut oil to the nano-calcium carbonate suspension slurry under stirring for a surface treatment. The addition amount is 2.5% of the dry mass of calcium carbonate, and continue to stir for 20 minutes to obtain Nano-calcium carbonate preliminary modification solution;

[0044] The preparation method of the above-mentioned composite surface treatment agent: add palmitic acid and coconut oil to the reaction kettle with a mass ratio of 2:1, then add sodium hydroxide with 12% palmitic acid mass, and control the saponification reaction at 90°C. That is, the co...

Embodiment 3

[0049] A kind of surface treatment method that is applied to the nano-calcium carbonate of filling silicone sealant, comprises the following steps:

[0050] (1) Set the specific surface to 30m 2 / g of nano-calcium carbonate slurry was added to the reactor, stirred, and heated to 70°C to obtain nano-calcium carbonate suspension slurry;

[0051] (2) Slowly add a compound surface treatment agent composed of arachidic acid and coconut oil to the nano-calcium carbonate suspension under stirring for a surface treatment. The addition amount is 3.0% of the dry mass of calcium carbonate, and continue to stir for 20 minutes to obtain Nano-calcium carbonate preliminary modification solution;

[0052] The preparation method of the above-mentioned compound surface treatment agent: add arachidic acid and coconut oil to the reaction kettle with a mass ratio of 4:1, then add sodium hydroxide with 13% of the mass of arachidic acid, and control the saponification reaction at 95°C. That is, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com