Method for modifying surface of nano calcium carbonate

A nano-calcium carbonate, surface modification technology, applied in the direction of fibrous fillers, dyed low-molecular-weight organic compounds, etc., can solve the problems of high pH value, large amount of inorganic alkali, incomplete saponification, etc., and achieve high activation rate, The effect of low production cost and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

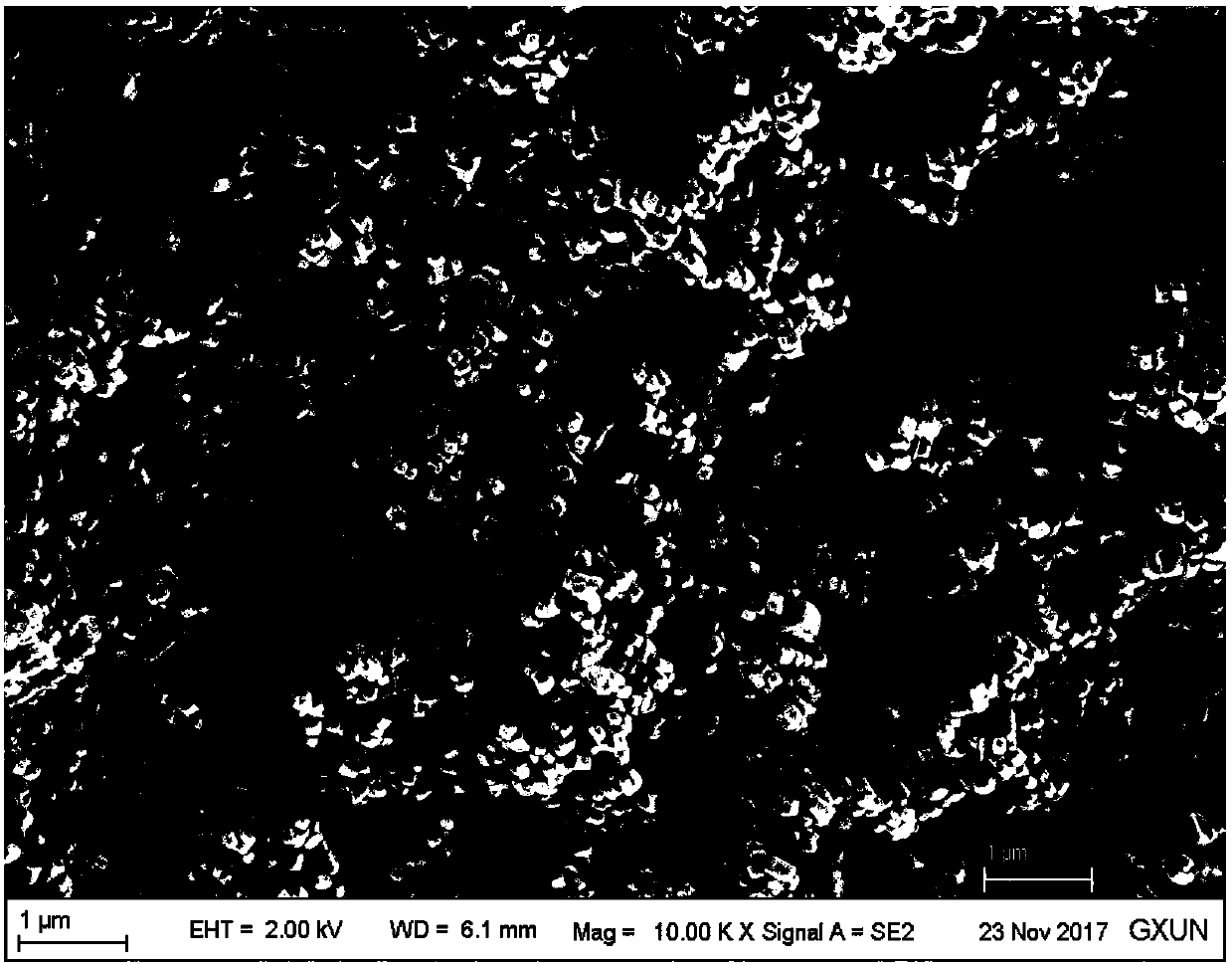

Embodiment 1

[0032] A method for surface modification of nano-calcium carbonate, comprising the following steps:

[0033] S1: Adjust the specific gravity of the refined milk of lime to 1.065, add it into the bubbling carbonation reaction kettle, and then pass in a mixed gas containing 33% carbon dioxide to carry out the carbonation reaction, and the carbonation to pH=7.0 is the end point, and the specific surface area is obtained. 24.6m 2 / g of nano-calcium carbonate suspension;

[0034] S2: Add ethylenediaminetetraacetate (disodium EDTA) stabilizer to the nano-calcium carbonate suspension, the dosage of the stabilizer is 0.5% of the dry mass of calcium carbonate, the temperature is controlled at 55° C., and the temperature is kept for 20 minutes;

[0035] S3: After heating and melting the stearic acid modifier in water, add sodium dodecylbenzenesulfonate emulsifier, and stir for 20 min at a rotating speed of 150r / min to obtain a modifier emulsion; the stearic acid modifier The total con...

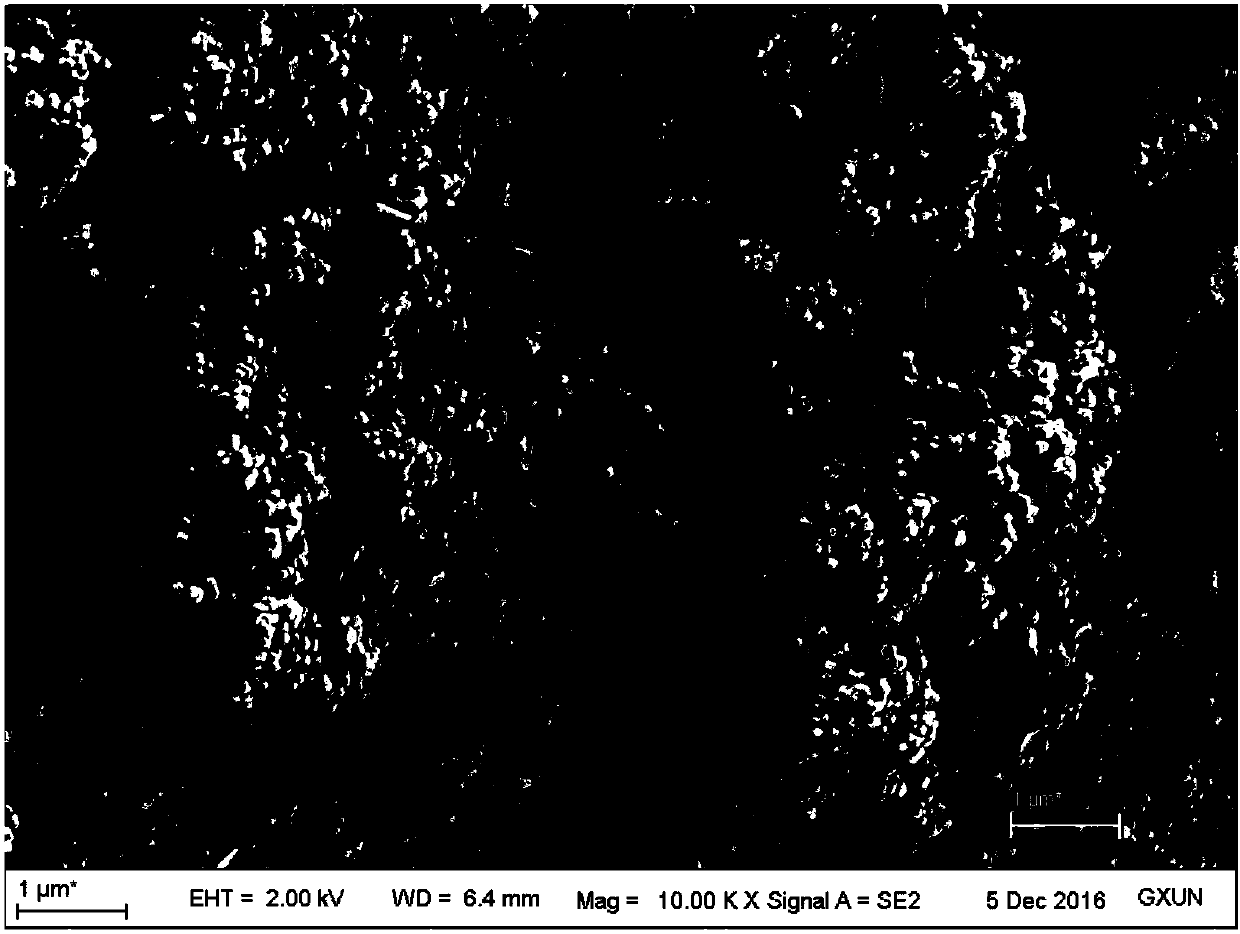

Embodiment 2

[0038] A method for surface modification of nano-calcium carbonate, comprising the following steps:

[0039] S1: Adjust the specific gravity of the refined milk of lime to 1.060, add it to the bubbling carbonation reaction kettle, and then pass in a mixed gas containing 35% carbon dioxide to carry out the carbonation reaction, and the carbonation to pH=7.0 is the end point, and the specific surface area is obtained as 22.8m 2 / g of nano-calcium carbonate suspension;

[0040] S2: adding sodium nitrilotriacetate (NTA) stabilizer to the nano-calcium carbonate suspension, the dosage of the stabilizer is 2.5% of the dry mass of calcium carbonate, the temperature is controlled at 60° C., and the temperature is kept for 20 minutes;

[0041] S3: After heating and melting the arachidic acid modifier in water, add a diglycerin polypropylene glycol ether emulsifier, and stir for 10 minutes at a rotating speed of 300r / min to obtain a modifier emulsion; the total amount of the arachidic a...

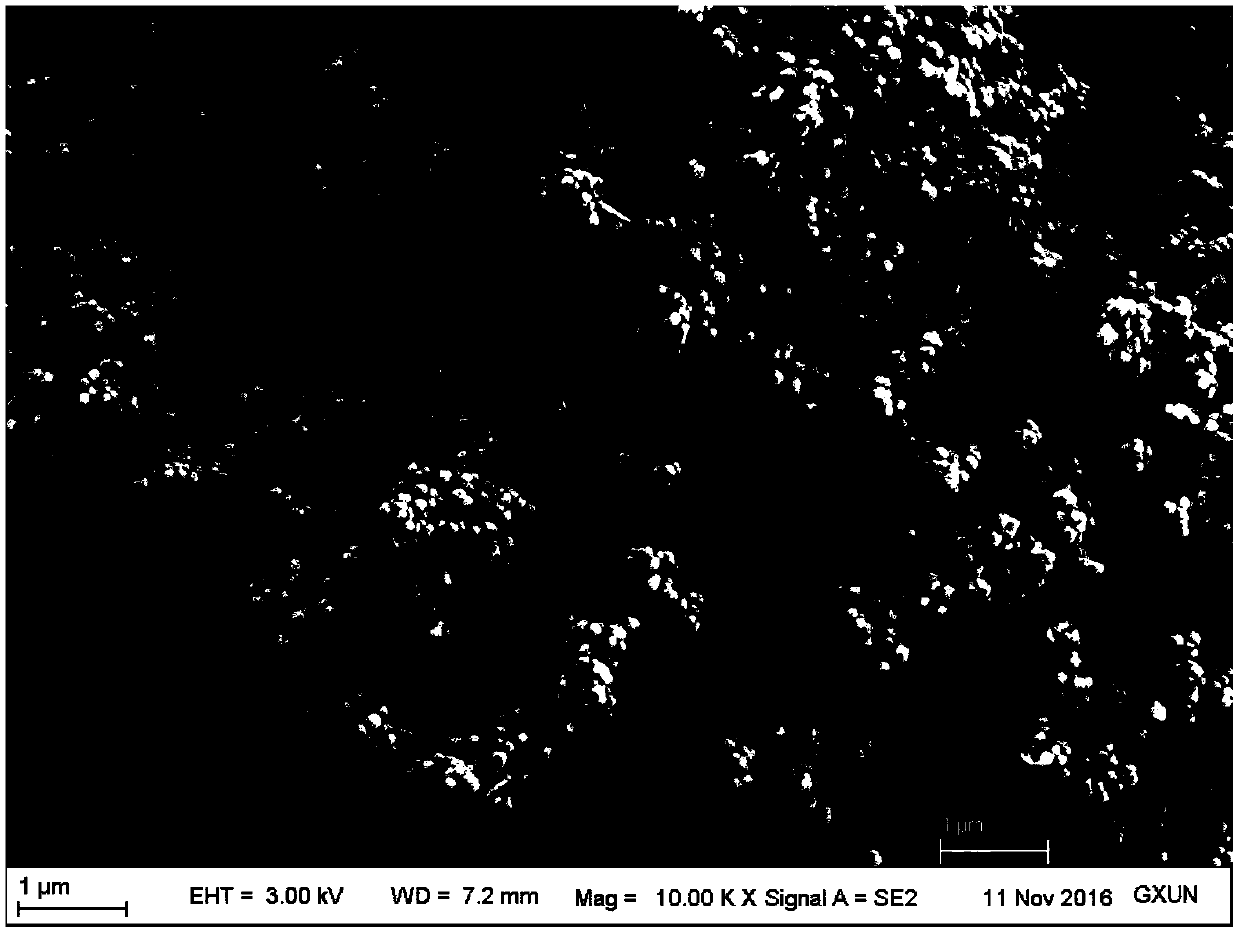

Embodiment 3

[0044] A method for surface modification of nano-calcium carbonate, comprising the following steps:

[0045] S1: Adjust the specific gravity of the refined milk of lime to 1.070, add it into the bubbling carbonation reaction kettle, and then pass in a mixed gas containing 33% carbon dioxide to carry out the carbonation reaction, and the carbonation to pH=7.0 is the end point, and the specific surface area is obtained. 28.9m 2 / g of nano-calcium carbonate suspension;

[0046] S2: Add ethylenediamine tetramethylene phosphate (EDTMPS) stabilizer to the nano-calcium carbonate suspension, the amount of the stabilizer is 1.5% of the dry mass of calcium carbonate, the temperature is controlled at 50 ° C, and the temperature is kept for 30 minutes;

[0047] S3: After heating and melting the lauric acid modifier in water, add a fatty alcohol polyoxyethylene ether emulsifier, and stir for 30 minutes at a rotating speed of 100r / min to obtain a modifier emulsion; the total amount of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com