Preparation method of nano-calcium carbonate SCC-2 special for silicone sealant

A silicone sealant, SCC-2 technology, applied in the direction of calcium carbonate/strontium/barium, nanotechnology, etc., can solve the problems of poor dispersion, poor thixotropy and leveling, poor production stability, etc., to optimize processing performance , the effect of excellent thixotropic properties and anti-sag properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

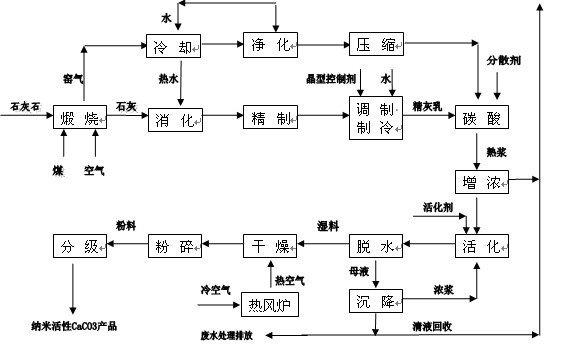

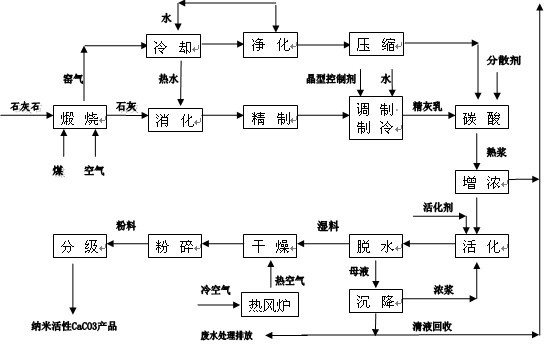

[0022] Embodiment: the preparation method of nano-calcium carbonate SCC-2 special for silicone sealants, using limestone as raw material, first crush the large limestone into limestone with a particle size of 75-150mm, and then mix it with anthracite with a particle size of 20-40mm The coal blending ratio (100:12~100:15), a certain interval (2h), and a certain total amount (determined by the production capacity) are added to the lime kiln or muffle furnace for calcination reaction with air, and the air is required ( The excess air coefficient is 1.05—1.10) from the lime kiln or muffle furnace (forced ventilation or natural ventilation), and the generated lime is produced at a certain interval (2h, in coordination with the feeding, feeding first and then harvesting), a certain temperature (60-80°C) from the bottom of the lime kiln, CO 2 Then continuously press a certain temperature (120-150°C) to leave the kiln from the top of the lime kiln.

[0023] The lime from the bottom o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com