Modified wollastonite, and preparation method and application thereof

A wollastonite and modification technology, which is applied in the field of modified wollastonite and its preparation, can solve the problems that the mechanical properties of PP materials are not significantly improved, the mechanical properties of products are not significantly improved, and the oil absorption value is not significantly improved. , to achieve the effect of improving mechanical properties, improving binding ability, and improving interface interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

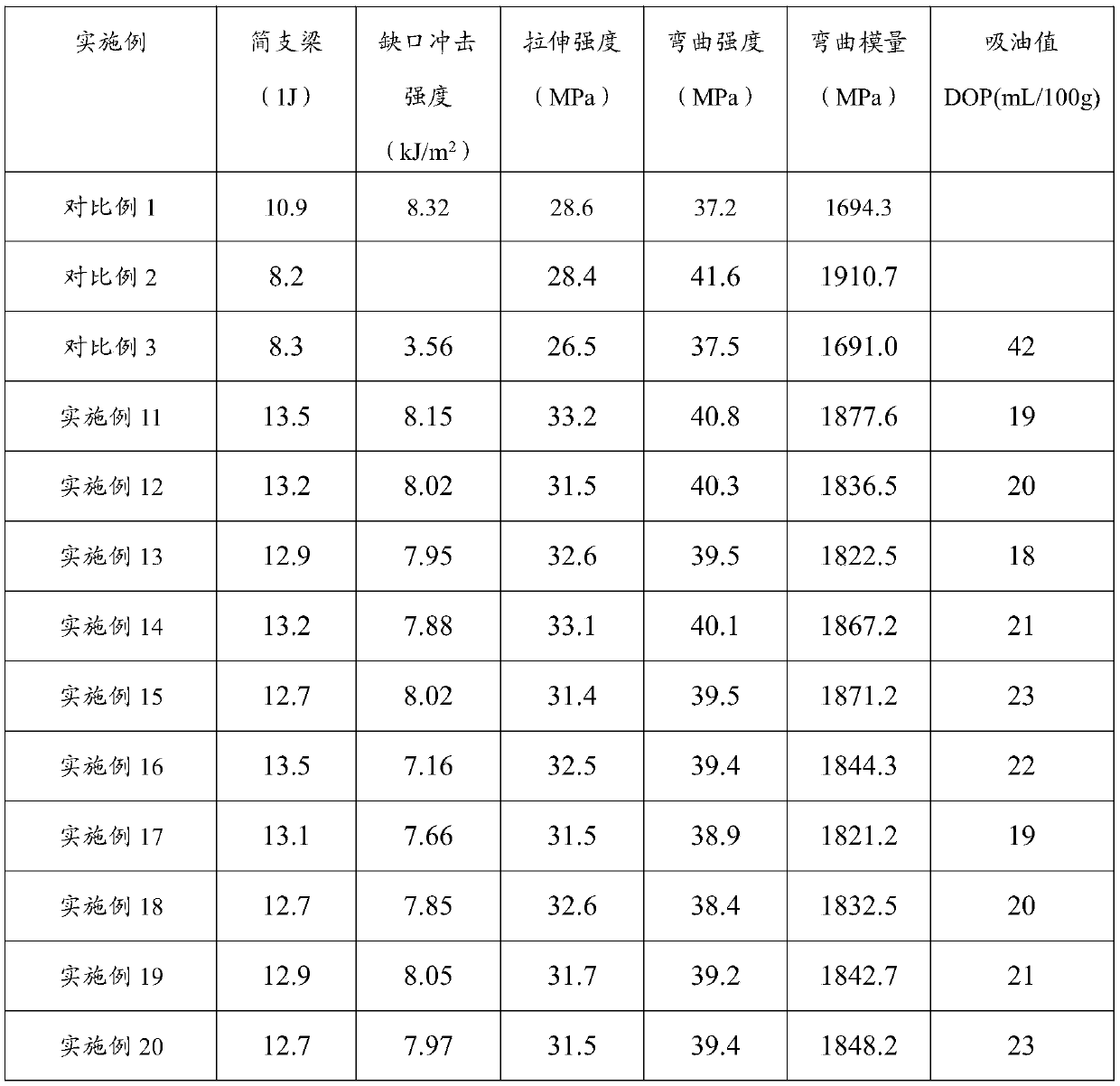

Examples

preparation example Construction

[0018] The invention provides a preparation method of the modified wollastonite. The wollastonite is mixed with a titanate coupling agent, stearic acid and fatty acid polyoxyethylene ester, and modified to obtain the modified wollastonite.

[0019] In the present invention, the particle size of the wollastonite is preferably 3-9 μm, more preferably 4-6 μm. In an embodiment of the present invention, the wollastonite is preferably acicular wollastonite, and further, the acicular wollastonite is preferably wollastonite powder (GY2000) produced by Jiangxi Guangyuan Chemical Co., Ltd. In the present invention, the wollastonite is used as a filler in engineering plastics, which can improve the mechanical properties and anti-aging properties of plastic products, and play a role in reinforcement and reinforcement; it can partially replace talcum powder and titanium dioxide as fillers, thereby reducing the cost of products .

[0020] The present invention has no special requirements o...

Embodiment 1

[0037] 1000g wollastonite powder (GY2000) and modifier (the quality of titanate coupling agent is 1.4% of the acicular wollastonite quality, the quality of stearic acid is 1.4% of the acicular wollastonite quality, fatty acid poly The quality of oxyethylene ester is 0.7% of the mass of acicular wollastonite) together in a high-speed stirrer, stirred at 1000rpm and heated to 120°C. At this time, start timing, and the modification time is 45min. material to obtain wollastonite modified powder.

Embodiment 2

[0039] 1000g wollastonite powder (GY2000) and modifier (the quality of titanate coupling agent is 1.0% of the acicular wollastonite quality, the quality of stearic acid is 1.0% of the acicular wollastonite quality, fatty acid poly The quality of oxyethylene ester is 0.5% of the mass of acicular wollastonite) together in a high-speed stirrer, stirred at 1000rpm and heated to 120°C. At this time, start timing, and the modification time is 45min. After natural cooling, the material to obtain wollastonite modified powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com