Gloss-adjustable inorganic powder composition for extinction and application of gloss-adjustable inorganic powder composition

A technology of inorganic powder and composition, applied in the direction of dyeing organosilicon compound treatment, application, inorganic pigment treatment, etc., can solve problems such as incompatibility, and achieve the effects of easy production control, clear function, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

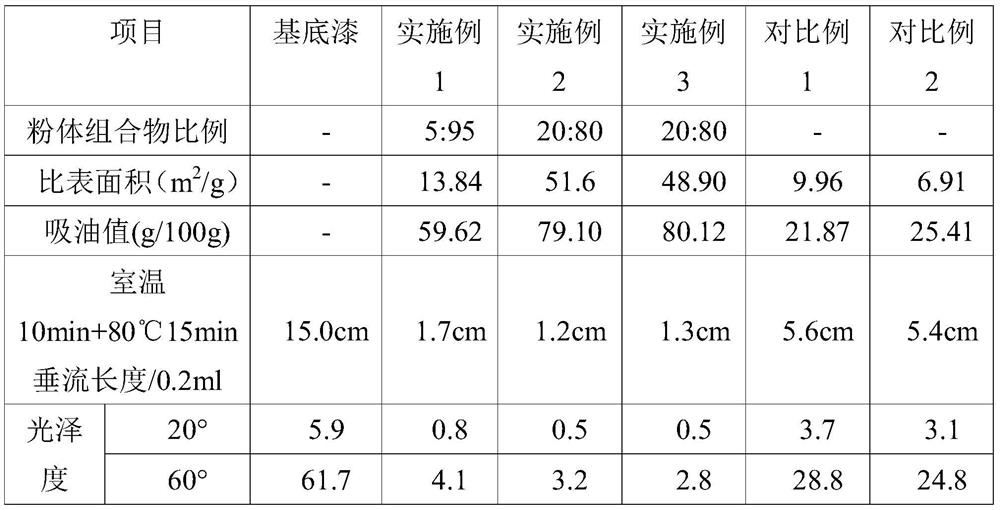

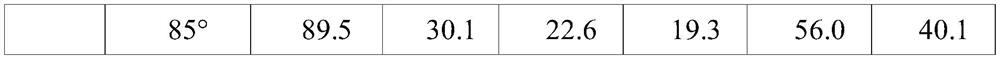

Examples

Embodiment 1

[0032] Preparation of porous silica powder:

[0033] Step (1): Add nano-silica into the water, stir, turn on and heat to a temperature of 40°C to obtain a mixed slurry;

[0034] Step (2): Adjust the pH value of the slurry to 5;

[0035] Step (3): Add the coupling agent while stirring, and react for 2 hours to obtain the reaction product;

[0036] Step (4): the reaction product is ion-washed, filtered, dried, and pulverized to obtain the porous silica powder of the present invention;

[0037] The amount of reaction material is calculated by mass in a ratio of water: nano silica: coupling agent=100:5:1. The particle size of the nano-silica is 50nm, and the coupling agent is methyltrimethoxysilane.

[0038] The obtained porous silica powder has a median particle size of 10um and a specific surface area of 240m 2 / g, through BJH method (desorption method) to analyze the channel diameter, the average channel diameter is 3nm.

[0039] The porous silica powder and the fused silica powder are ...

Embodiment 2

[0042] Preparation of porous silica powder:

[0043] Step (1): Add nano-silica into the water, stir, turn on and heat to a temperature of 80°C to obtain a mixed slurry;

[0044] Step (2): Adjust the pH value of the slurry to 1;

[0045] Step (3): Add the coupling agent while stirring, and react for 8 hours to obtain the reaction product;

[0046] Step (4): the reaction product is ion-washed, filtered, dried, and pulverized to obtain the porous silica powder of the present invention;

[0047] The amount of reaction material is calculated by mass in a ratio of water: nano silica: coupling agent=100:15:6. The particle size of the nano-silica is 5nm, and the coupling agent is vinyltrimethoxysilane.

[0048] The obtained porous silica powder has a median particle size of 6.0um and a specific surface area of 220m. 2 / g, through BJH method (desorption method) to analyze the diameter of the pores, the average diameter of the pores is 2nm.

[0049] The porous silica powder and the fused silica ...

Embodiment 3

[0052] Preparation of porous silica powder:

[0053] Step (1): Add nano-silica into the water, stir, turn on and heat to a temperature of 80°C to obtain a mixed slurry;

[0054] Step (2): Adjust the pH value of the slurry to 1;

[0055] Step (3): Add the coupling agent while stirring, and react for 8 hours to obtain the reaction product;

[0056] Step (4): the reaction product is ion-washed, filtered, dried, and pulverized to obtain the porous silica powder of the present invention;

[0057] The amount of the reaction material is calculated by mass in a ratio of water: nano silica: coupling agent=100:10:4. The particle size of the nano-silica is 5nm, and the coupling agent is vinyltrimethoxysilane.

[0058] The obtained porous silica powder has a median particle size of 3.0um and a specific surface area of 180m 2 / g, through BJH method (desorption method) to analyze the diameter of the pores, the average diameter of the pores is 2.5nm.

[0059] The porous silica powder and fused silica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Median granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com