A kind of graphene-containing composite electronic heat conduction and heat dissipation material and its preparation method and application

A heat-dissipating material, graphene technology, applied in heat exchange materials, chemical instruments and methods, fibrous fillers, etc., can solve the problems of high thermal conductivity and low thermal radiation rate of metals, achieve simple operation and save production costs , easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

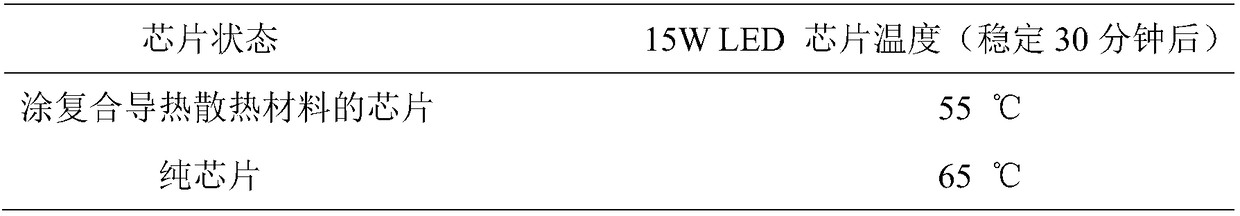

Examples

Embodiment 1

[0027] At room temperature, mix 5g of graphene, 30g of aluminum isopropoxide, 50mL of ethyl orthosilicate, 6mL of n-butyl titanate, and 350mL of ethanol, stir for 15 minutes, and mix well; then slowly add 8mL of ammonia water dropwise, and continue stirring for 2 hours , separating the obtained reaction liquid from solid to liquid, and drying the solid to obtain the graphene / silicon dioxide / alumina / titania composite filler.

[0028] At room temperature, add the obtained graphene / silicon dioxide / alumina / titania composite filler into 150g of water-based acrylic resin, continue stirring for 30 minutes, then add 20g of magnesium oxide, stir and disperse for 2 hours, and obtain a graphene-containing composite filler. Electronic heat conduction and heat dissipation materials.

Embodiment 2

[0030] At room temperature, mix 15g of sulfur-doped graphene, 75g of aluminum isopropoxide, 100mL of ethyl orthosilicate, 3mL of n-butyl titanate, and 750mL of ethanol, stir for 15 minutes, and mix well; then slowly add 15mL of ammonia water dropwise, continue After stirring for 2 hours, the obtained reaction solution was separated from solid to liquid, and the solid was dried to obtain the graphene / silicon dioxide / alumina / titania composite filler.

[0031] At room temperature, add the obtained graphene / silicon dioxide / alumina / titania composite filler into 500g of water-based polyurethane, continue stirring for 30 minutes, then add 60g of boron nitride, stir and disperse for 2 hours, and obtain a graphene-containing composite filler. Electronic heat conduction and heat dissipation materials.

Embodiment 3

[0033] At room temperature, 5g of phosphorus-doped graphene, 15g of aluminum nitrate, 25mL of ethyl orthosilicate, 8mL of titanium tetrachloride, and 150mL of ethanol were stirred together for 15 minutes and mixed uniformly; then slowly added dropwise an aqueous solution containing 5g of sodium bicarbonate, Stirring was continued for 2 hours, the obtained reaction solution was separated from solid to liquid, and the solid was dried to obtain the graphene / silicon dioxide / alumina / titania composite filler.

[0034] At room temperature, the obtained graphene / silicon dioxide / alumina / titania composite filler was added to 75g of water-based epoxy resin, continued to stir for 30 minutes, then added 10g of iron oxide, stirred and dispersed for 2 hours to obtain graphene-containing Composite electronic heat conduction and heat dissipation materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com