Method for preparing air blocking agent for tire inner liners by taking black talc as raw material

An air blocker and airtight layer technology, applied in chemical instruments and methods, fibrous fillers, climate sustainability, etc., can solve the problems of low product purity, difficult exclusion of associated minerals and heavy metal impurities, and rubber matrix affinity There are still some problems to be improved to achieve the effect of shortening the process flow, excellent air tightness and certain reinforcement performance, modification effect and improvement of crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0031] A method for preparing an air stopper for a tire inner liner using black talc as a raw material, is characterized in that it comprises the following steps:

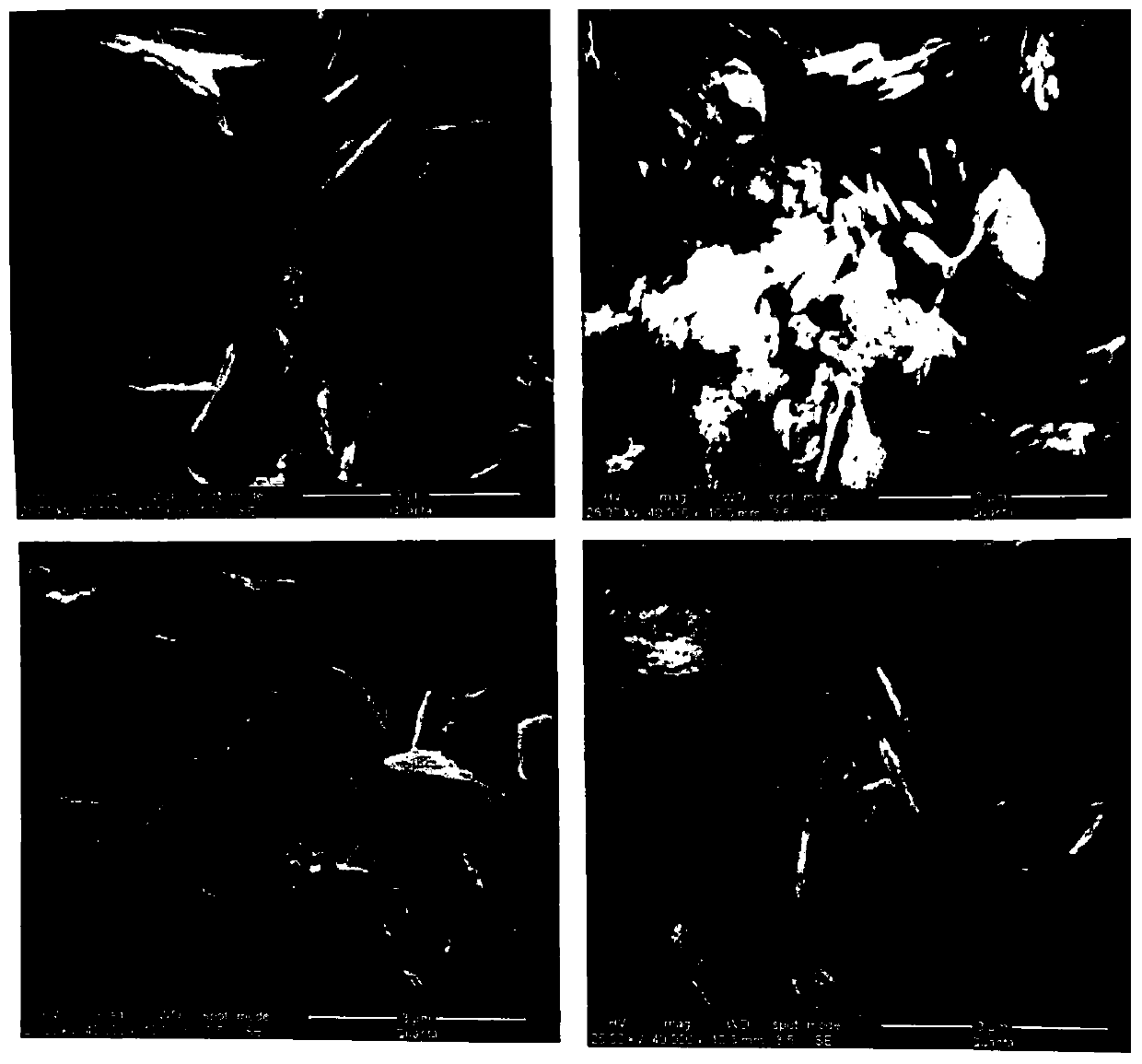

[0032] (1) Raw ore pretreatment: After the massive raw ore is washed with water, associated minerals such as quartz, calcite, dolomite, and magnetite are manually removed, and the raw ore with high talc content and good sheet structure is retained.

[0033] (2) Coarse crushing: Use the jaw crusher to crush the raw ore to 2-5cm, then use the roller crusher to crush the raw ore to 2-5mm, and finally use the Raymond mill to crush the raw ore to 80 mesh.

[0034] (3) Magnetic separation: select electromagnetic dry type automatic magnetic separator, under the magnetic field strength of 12000GS, the material after coarse crushing is screened, and iron oxide content is 0.05% in the material after magnetic separation.

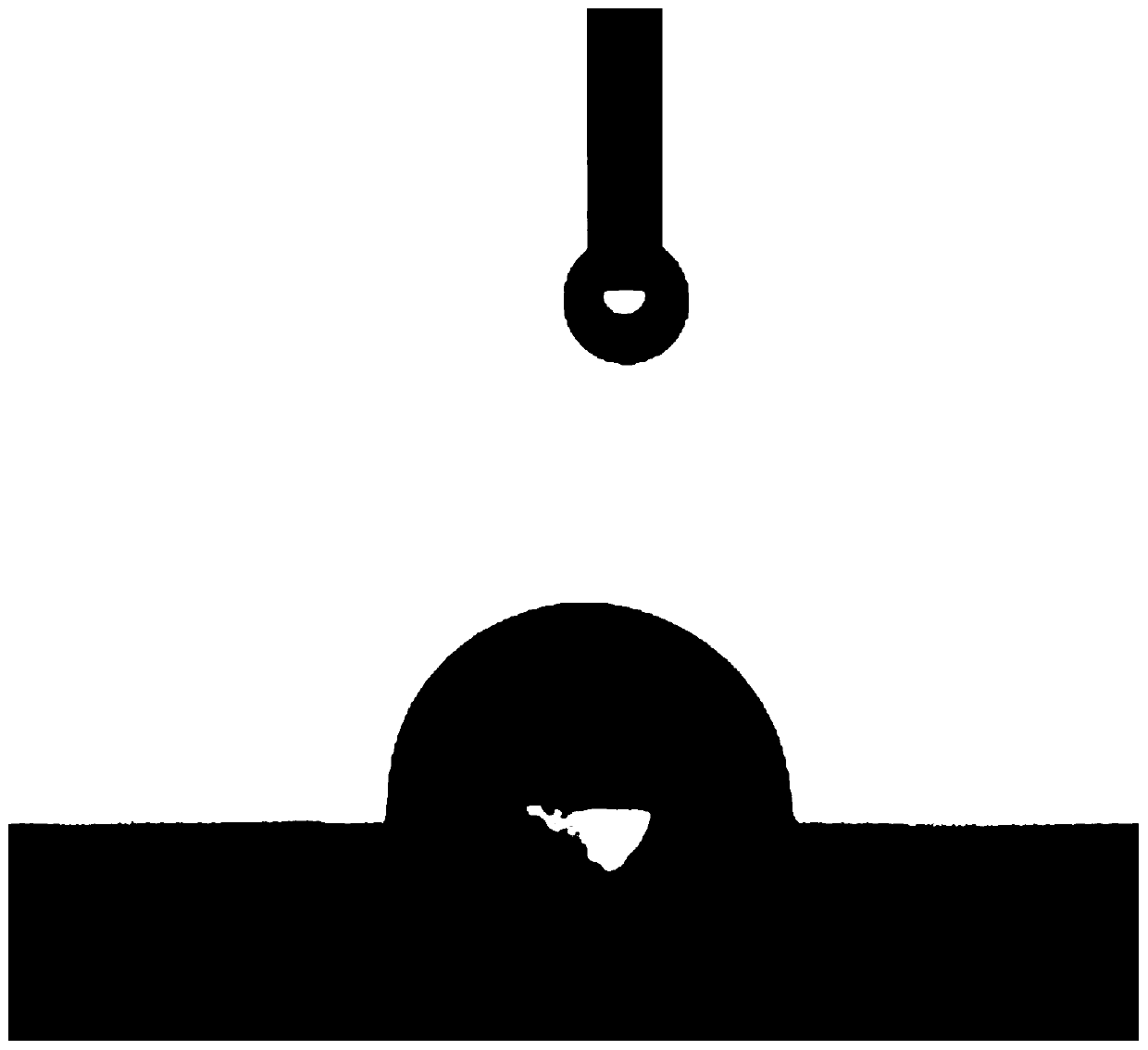

[0035] (4) Integration of ultrafine pulverization and modification: Utilize 0.7MPa, superheated air flow...

Embodiment approach 2

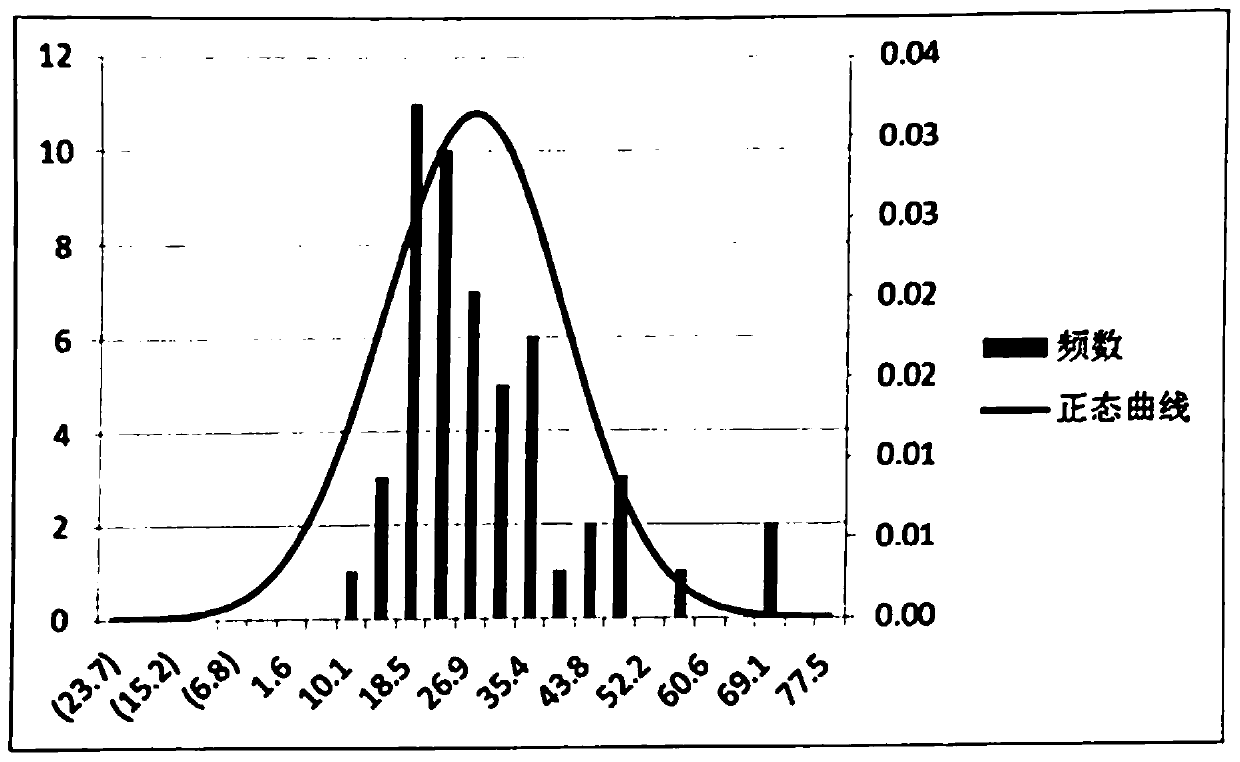

[0041]Utilize the product prepared in embodiment 1, utilize bromobutyl rubber to do airtightness test under different air blocking agent dosages.

[0042] The rubber formula is: bromobutyl rubber (100 parts), stearic acid (1 part), naphthenic oil V700 (9 parts), sulfur (1 part), zinc oxide (3.5 parts), accelerator DM (1.3 parts ), leveling agent (7 parts), resin (4 parts), air blocker (30, 40, 50 and 60 parts). Using the 1-stage mixing process, add the raw materials in the formula to the internal mixer one by one and mix them evenly, then make triangular bags in the open mixer for 3 times, and pass them thinly for 3 times. After standing for 6 hours, use a flat vulcanizer to vulcanize for 20 minutes under the pressure of 15Mpa. , Test the airtightness after vulcanization and molding for 24 hours. The airtightness of the samples is shown in Table 2.

[0043] Table 2 The relationship between the amount of air barrier agent and air permeability in bromobutyl rubber

[0044] ...

Embodiment approach 3

[0046] Utilize the product prepared in embodiment 1, utilize styrene-butadiene rubber to do air-tightness test under different air blocking agent dosages. The rubber formula is: styrene-butadiene rubber (100 parts), stearic acid (1 part), sulfur (1.75 parts), zinc oxide (3 parts), accelerator NS (1 part), air blocker (30, 40, 50 and 60 servings). Using the 1-stage mixing process, add the raw materials in the formula to the internal mixer one by one and mix them evenly, then make a triangular bag in the open mixer for 3 times, thin pass 3 times, and after standing for 6 hours, use a flat vulcanizer to vulcanize for 17 minutes under a pressure of 15Mpa. , Test the air tightness after vulcanization and molding for 24 hours. The airtightness of the samples is shown in Table 3.

[0047] Table 3 Relation table between air blocking agent dosage and air permeability in styrene-butadiene rubber

[0048] Blocker dosage (parts) 0 30 40 50 60 Air permeability Q(×10-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com