Preparation method of modified illite for improving performance of natural rubber

A technology of natural rubber and illite, applied in chemical instruments and methods, fibrous fillers, dyeing and washing, etc., can solve the problems of insignificant improvement in the performance of composite materials and low improvement in mechanical properties, and achieve excellent mechanical properties. The effect of short reaction time and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

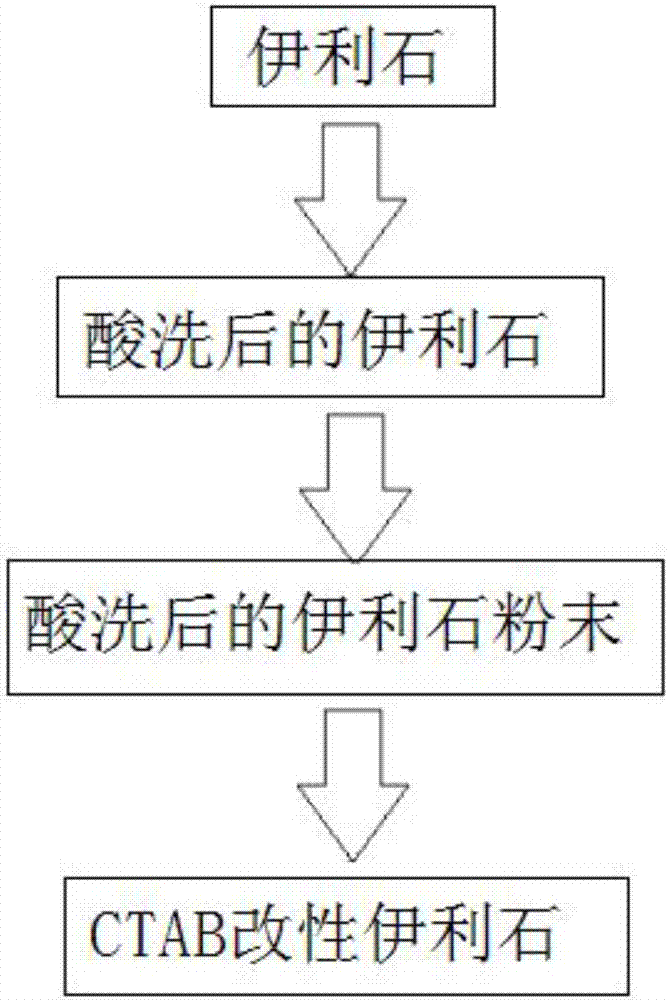

[0030] A method for preparing modified illite for improving the performance of natural rubber, comprising the following steps, and the following steps are carried out in sequence,

[0031] Step 1. Put illite into 0.5% HCl solution with a mass concentration of 0.5%, in which the solid-to-liquid ratio is 1:40 in g / ml, stir in a constant temperature water bath at 50°C at 600rad / min for 1.5h, and pickle the illite Stand still and filter after cooling down to normal temperature;

[0032] Step 2, the illite filtered in the step 1 is repeatedly stirred and rinsed in a three-necked flask with deionized water until the pH value of the deionized water in the three-necked flask is 7, and the illite obtained by filtering is washed in a blast type Dry in a constant temperature drying oven at 60°C for 24 hours, grind into powder particles, and obtain illite powder after pickling;

[0033] Step 3: Take 5g of the acid-washed illite obtained in the step 2, 200mL volume concentration of 50% is...

Embodiment 2

[0037] A method for preparing modified illite for improving the performance of natural rubber, comprising the following steps, and the following steps are carried out in sequence,

[0038] Step 1. Put illite into 5% HCl solution with a mass concentration of 5%, wherein the solid-to-liquid ratio is 1:40 in g / ml, stir in a constant temperature water bath at 70°C at 600rad / min for 2 hours, and statically pickle the illite Filter after cooling down to normal temperature;

[0039] Step 2, the illite filtered in the step 1 is repeatedly stirred and rinsed in a three-necked flask with deionized water until the pH value of the deionized water in the three-necked flask is 7, and the illite obtained by filtering is washed in a blast type Dry in a constant temperature drying oven at 60°C for 24 hours, grind into powder particles, and obtain illite powder after pickling;

[0040] Step 3: Take 5g of the acid-washed illite obtained in the step 2, 200mL volume concentration of 50% isopropan...

Embodiment 3

[0044] 1. Preparation of modified illite:

[0045] Take 10g illite and put it into 1% HCl solution, the solid-liquid ratio is 1:40 according to g / ml, 60°C constant temperature water bath, 600rad / min stirring for 1h, the illite after pickling is left to stand, cooled and then filtered;

[0046] Stir and rinse the three-necked flask with deionized water repeatedly until the pH value is 7, filter the sample and dry it for 24 hours, then grind it into powder particles to obtain illite after pickling;

[0047] Take 5g of the above acid-washed illite, add 200mL of 50% isopropanol aqueous solution and 0.4g of CTAB into a 500ml three-necked flask reactor. React under microwave and 80°C for 1h, let it stand at room temperature, centrifuge at 5000rad / min for 5min, dry at 60°C for 24h, and then use an agate mortar to grind to obtain CTAB modified illite.

[0048] 2. Preparation of illite and natural rubber composite materials

[0049] Mass ratio of refining materials: raw rubber 100, sul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com