Preparation method of high-dispersity ultramarine pigment, pigment obtained through preparation method and application of pigment

A technology of high dispersibility and ultramarine blue, applied in the field of preparation and application of ultramarine blue pigments, can solve the problems of lens Tyndall effect, poor dispersibility, affecting product performance, etc., and achieve the effects of reducing sedimentation, improving dispersion, and improving dispersion performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Take 1g of ultramarine blue pigment, 30g of methylene chloride and 20g of mixed zirconia ball milling beads in a 100mL ball milling jar, add 0.5g of diethylene glycol bischloroformate, 0.5g of triethylamine and 0.03g of DMF at the same time, seal the jar Then place it in a planetary ball mill and react at 400rpm for 3h to obtain an acyl chloride ultramarine dispersion; then close the ball mill, open the ball mill tank, add 0.35g of diethylamine to it, seal the tank, and continue to react at 400rpm for 3h. After the end, the mixed solution is firstly removed by dichloromethane, then washed with ethanol and deionized water to remove unreacted ester, amine and ammonium salt of acid binding, and finally dried and ground to obtain modified ultramarine blue.

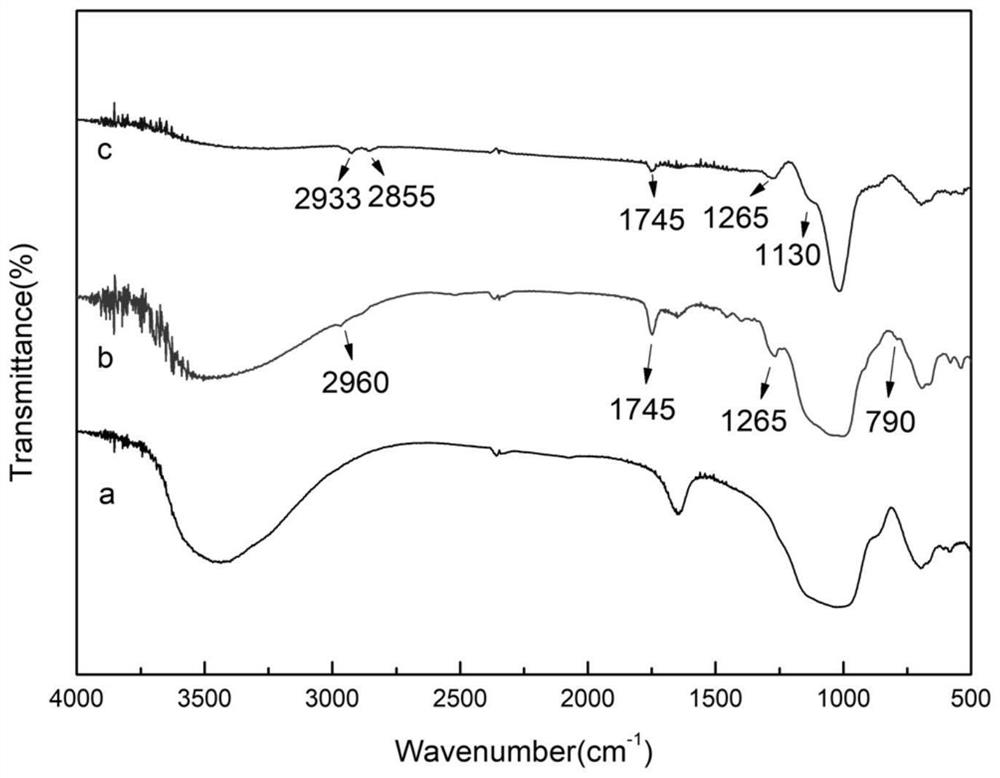

[0038] see figure 1 , compared with the ultramarine blue raw material (a), the acyl chloride ultramarine (b) is respectively at 790cm -1 、1265cm -1 、1745cm -1 、2960cm -1 There is a new absorption peak at 790cm -1 T...

Embodiment 2

[0041] Take 1g of ultramarine blue pigment, 25g of dichloroethane and 30g of mixed zirconia ball milling beads in a 100mL ball milling jar, add 0.4g of diethylene glycol bischloroformate, 1.0g of triethylamine and 0.02g of DEF at the same time, seal After the tank is placed in a planetary ball mill, react at a speed of 450rpm for 3.5h to obtain an acid chloride ultramarine dispersion; then close the ball mill, open the ball mill tank, add 0.40g of diethylamine to the tank, and continue to react at a speed of 450rpm 3.5h. After the mixture is finished, the dichloromethane is removed first, then the unreacted ester, amine and acid-binding ammonium salt are removed by washing with ethanol and deionized water, and finally the modified ultramarine is obtained by drying and grinding.

Embodiment 3

[0043] Take 1g of ultramarine blue pigment, 28g of trichloroethane and 40g of mixed zirconia ball milling beads in a 100mL ball milling jar, add 0.6g of diethylene glycol bischloroformate, 0.8g of pyridine and 0.05g of DMF at the same time, after sealing the jar Placed in a planetary ball mill, reacted at 500rpm for 4h to obtain acyl chloride ultramarine dispersion; then closed the ball mill, opened the ball mill tank, then added 0.50g of diethylamine to seal the tank, and continued to react at 500rpm for 4h. After the mixture is finished, the dichloromethane is removed first, then the unreacted ester, amine and acid-binding ammonium salt are removed by washing with ethanol and deionized water, and finally the modified ultramarine is obtained by drying and grinding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com