Anti-aging EB floor and preparation method thereof

An anti-aging and anti-aging agent technology, which is applied in chemical instruments and methods, organic chemistry, dyeing low-molecular organic compound treatment, etc., can solve the problems of paint film not being able to protect the floor, cracks, organic volatile emissions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

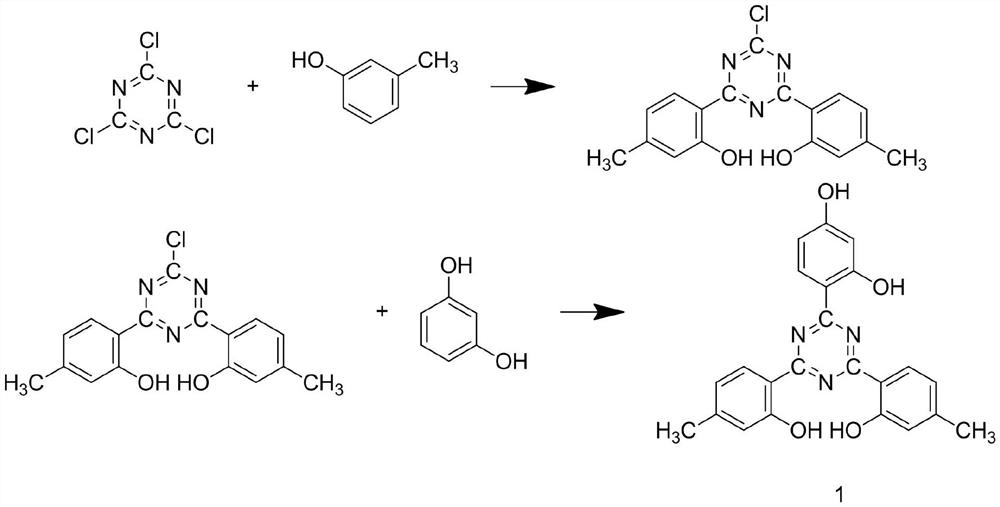

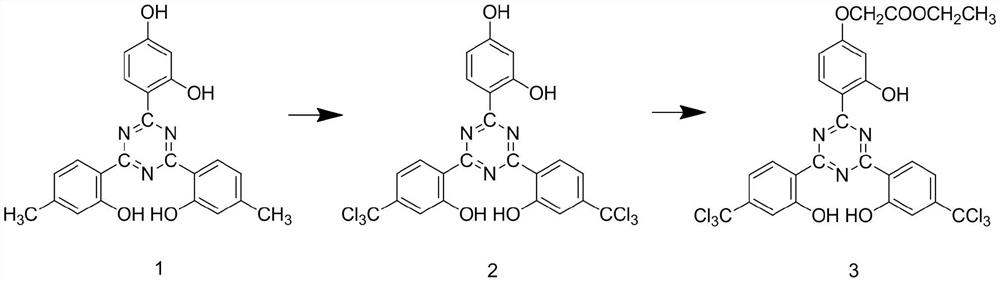

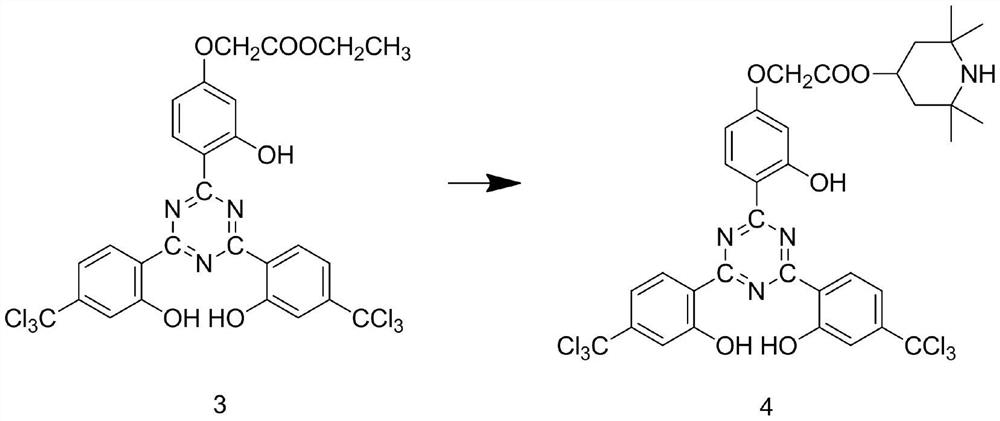

Image

Examples

Embodiment 1

[0040] An aging-resistant EB floor is made by the following steps:

[0041] Step S1: Mix N,N-dimethylaniline, p-hydroxyanisole, acrylic acid, and toluene until they are evenly mixed to prepare a drop solution, and add novolac epoxy resin to the reaction kettle, and set the temperature at 75°C Under the condition of stirring and adding dropwise liquid, dropwise adding time is 1h, after the dropping is completed, the temperature is raised at 85°C, and the reaction is carried out until the acid value in the reaction system reaches 0.5mgKOH / g, then the reaction is stopped , cooled to room temperature, the reactant was extracted 3 times with anhydrous ether to obtain a viscous substance, which was dried to obtain the first product;

[0042] Step S2: Add isophorone diisocyanate into the reaction kettle, add γ-aminopropyltriethoxysilane solution dropwise under the condition of an ice-water bath with a rotational speed of 60r / min, and react for 1 hour to obtain the second product , d...

Embodiment 2

[0051] An aging-resistant EB floor is made by the following steps:

[0052] Step S1: Mix N,N-dimethylaniline, p-hydroxyanisole, acrylic acid, and toluene until they are evenly mixed to prepare a drop solution, and add novolac epoxy resin to the reaction kettle at a temperature of 78°C Under the condition of stirring and adding dropwise liquid, dropwise adding time is 1.5h, after the dropwise addition is completed, the temperature is raised and the reaction is carried out at a temperature of 88°C until the acid value in the reaction system reaches 0.5mgKOH / g, then stop reacting, cooling to room temperature, extracting the reactant 4 times with anhydrous ether to obtain a viscous material, drying the viscous material to obtain the first product;

[0053] Step S2: Add isophorone diisocyanate into the reaction kettle, add γ-aminopropyltriethoxysilane solution dropwise under the condition of an ice-water bath with a rotating speed of 70r / min, and react for 1.3 hours to obtain the s...

Embodiment 3

[0062] An aging-resistant EB floor is made by the following steps:

[0063] Step S1: Mix N,N-dimethylaniline, p-hydroxyanisole, acrylic acid, and toluene until they are evenly mixed to prepare a drop solution, and add novolac epoxy resin to the reaction kettle at a temperature of 80°C Under the condition of stirring and adding dropwise liquid, dropwise adding time is 1.5h, after the dropwise addition is completed, the temperature is raised and the reaction is carried out at a temperature of 90°C until the acid value in the reaction system reaches 0.5mgKOH / g, then stop reacting, cooling to room temperature, extracting the reactant 5 times with anhydrous ether to obtain a viscous material, drying the viscous material to obtain the first product;

[0064] Step S2: Add isophorone diisocyanate into the reaction kettle, and add γ-aminopropyltriethoxysilane solution dropwise under the condition of an ice-water bath with a rotating speed of 80r / min, and react for 1.5 hours to obtain the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com