Amino polymerization inhibition modified heat-conducting particle and preparation method thereof

A thermally conductive particle and modified technology, applied in the field of additive manufacturing to reduce surface cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

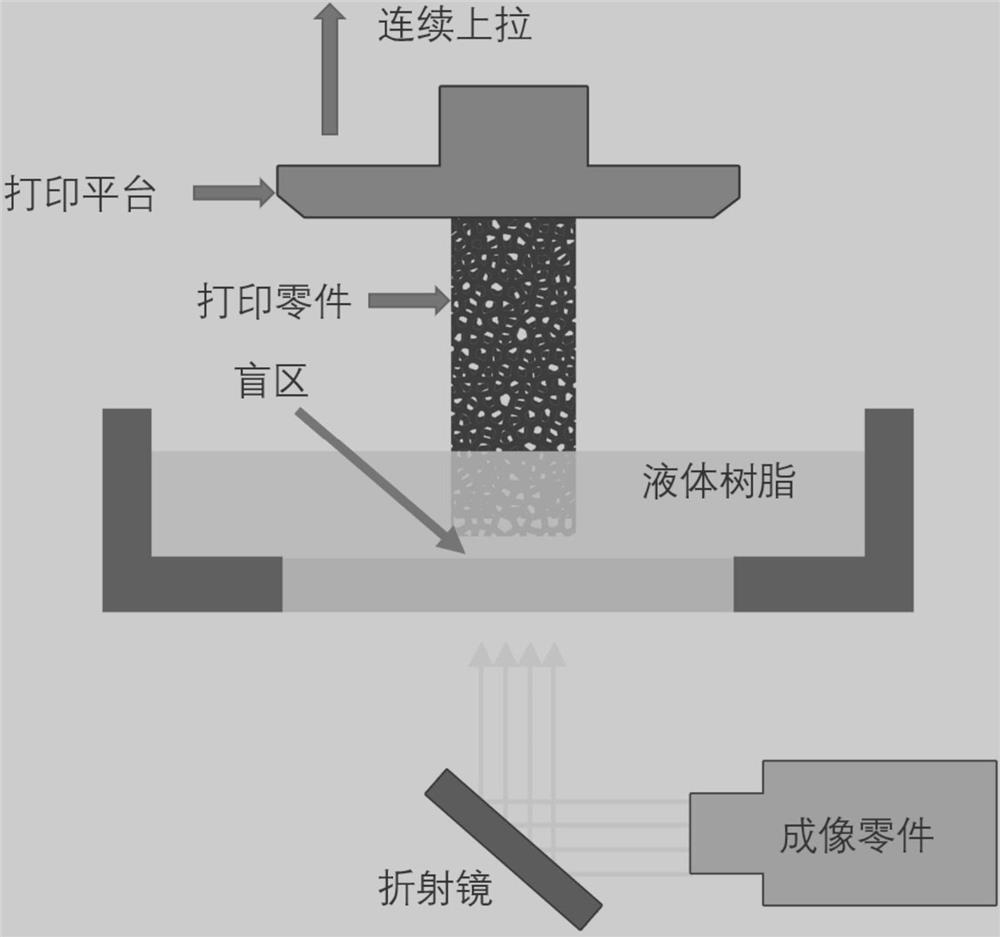

Method used

Image

Examples

Embodiment 1

[0055] The epoxy resin-based liquid photosensitive resin is 3D printed by using a PET light-transmitting release film, and the epoxy resin-based liquid photosensitive resin includes the following components in parts by weight:

[0056] 30 parts epoxy resin

[0057] Vinyl ether monomer 5 parts

[0058] Heterocyclic monomer 5 parts

[0059] Initiator 1 part

[0060] Pigment 0.1 part.

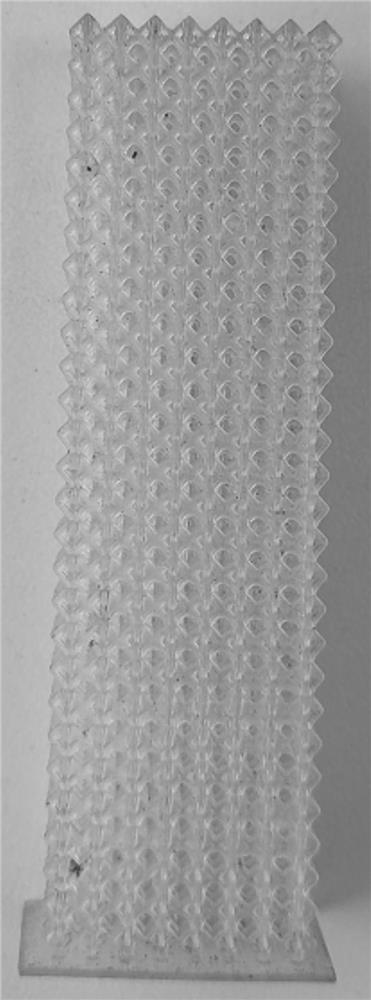

[0061] Amino polymerization-inhibited modified heat-conducting particles are added to the epoxy resin-based liquid photosensitive resin, and the mass concentration of the amino-inhibited polymerization-modified heat-conducted particles in the epoxy resin-based liquid photosensitive resin is 1%, and then the three-dimensional printing to be printed The CAD model of the object is sliced, and the thickness of the slice is 0.05mm. Finally, the printing platform is moved vertically upward at a speed of 200mm / h, and the 3D printed stereogram is obtained. figure 2 .

Embodiment 2

[0063] The epoxy resin-based liquid photosensitive resin is 3D printed by using a PET light-transmitting release film, and the epoxy resin-based liquid photosensitive resin includes the following components in parts by weight:

[0064] 50 parts of epoxy resin

[0065] Vinyl ether monomer 20 parts

[0066] Heterocyclic monomer 10 parts

[0067] Initiator 5 parts

[0068] 3 parts of paint.

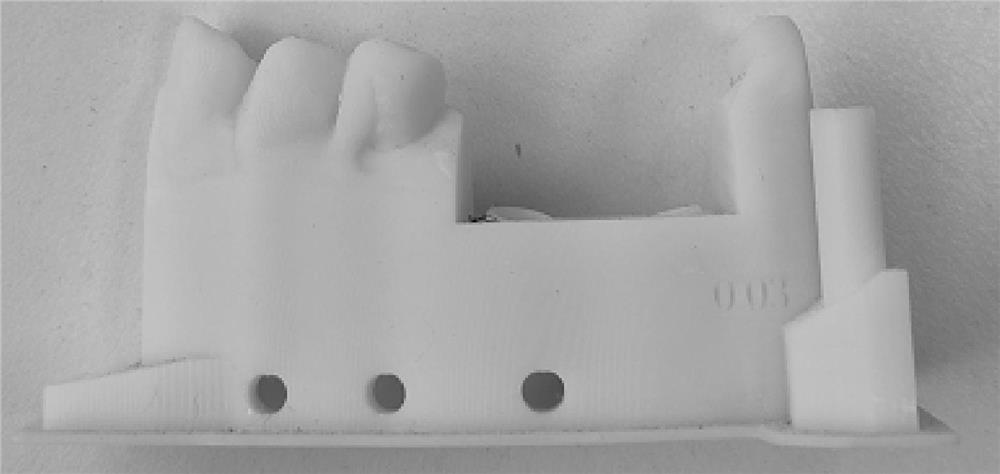

[0069] Amino polymerization-inhibited modified heat-conducting particles are added to the epoxy resin-based liquid photosensitive resin, and the mass concentration of the amino-inhibited polymerization-modified heat-conducting particles in the epoxy resin-based liquid photosensitive resin is 1.5%, and then the three-dimensional printing to be printed The CAD model of the object is sliced, and the thickness of the slice is 0.025mm. Finally, the printing platform is moved vertically upward at a speed of 100mm / h, and the 3D printed stereogram is obtained. image 3 .

Embodiment 3

[0071] The epoxy resin-based liquid photosensitive resin is 3D printed by using FEP light-transmitting release film, and the epoxy resin-based liquid photosensitive resin includes the following components in parts by weight:

[0072] 40 parts epoxy resin

[0073] Vinyl ether monomer 10 parts

[0074] Heterocyclic monomer 8 parts

[0075] Initiator 3 parts

[0076] 1 part of paint.

[0077] Amino polymerization-inhibited modified heat-conducting particles are added to the epoxy resin-based liquid photosensitive resin, and the mass concentration of the amino-inhibited polymerization-modified heat-conducting particles in the epoxy resin-based liquid photosensitive resin is 1.5%, and then the three-dimensional printing to be printed The CAD model of the object is sliced, and the slice thickness is 0.1mm. Finally, the printing platform is moved vertically upwards at a speed of 300mm / h, and the 3D printed stereogram is obtained. Figure 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com