High-thermal-conductivity boron nitride powder filler and preparation method thereof

A technology of boron nitride powder and high thermal conductivity, which is applied in chemical instruments and methods, fibrous fillers, heat exchange materials, etc., can solve the problems of affecting the thermal conductivity of resin composite materials, poor compatibility of organic matrix, uneven dispersion, etc. , to achieve the effect of improving heat conduction effect, good compatibility, and easy heat conduction network

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

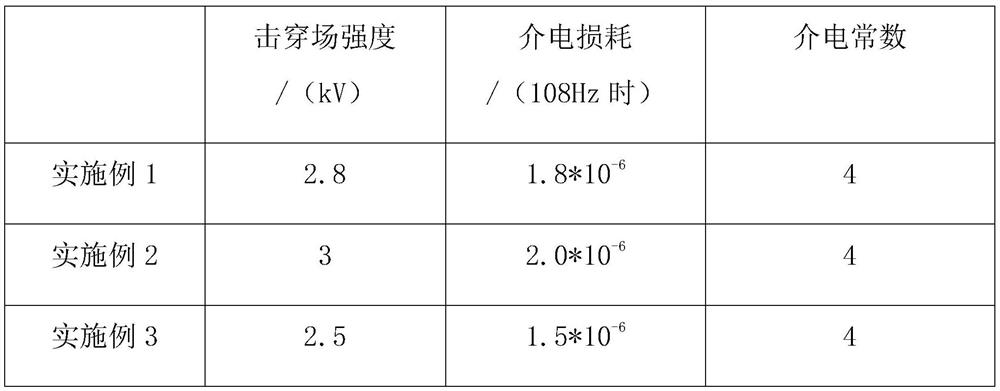

Embodiment 1

[0029] A high thermal conductivity boron nitride powder filler, the formula includes: sodium hydroxide, boron nitride, epoxy silane coupling agent, absolute ethanol and deionized water, the mass percentage of each component is: 25 Parts of sodium hydroxide, 40 parts of boron nitride, 25 parts of epoxy silane coupling agent, 15 parts of absolute ethanol and 10 parts of deionized water.

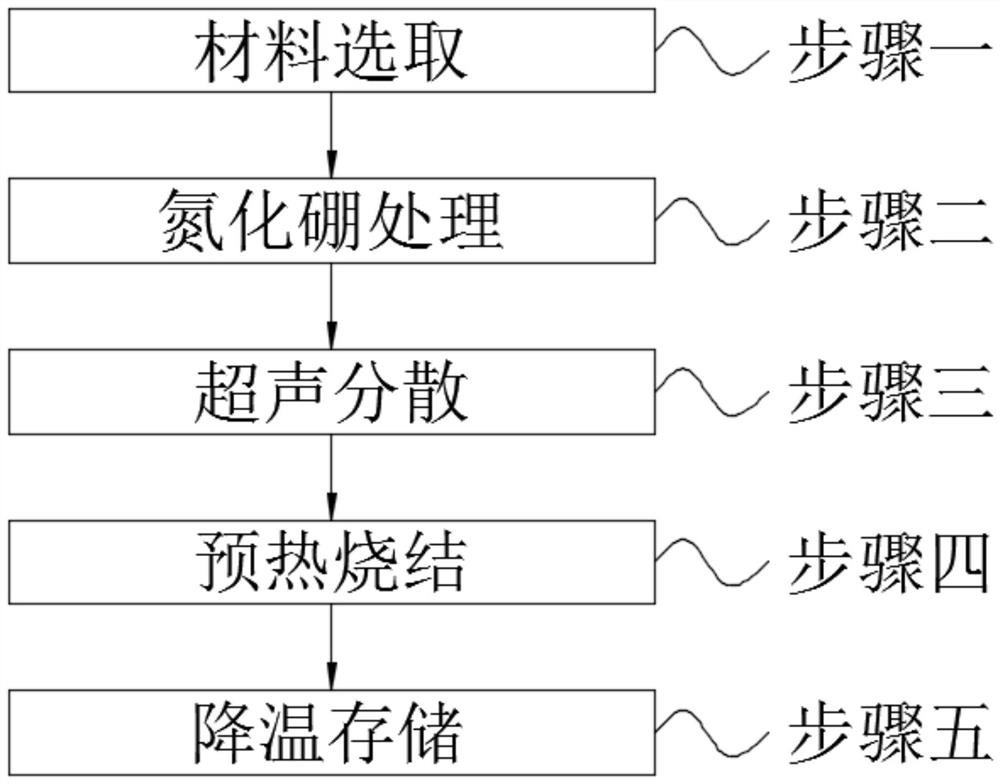

[0030] A method for preparing a high thermal conductivity boron nitride powder filler, comprising the following steps: Step 1, material selection; Step 2, boron nitride treatment; Step 3, ultrasonic dispersion; Step 4, preheating and sintering; Step 5, cooling storage ;

[0031] Wherein in the above-mentioned step one, according to the content of each component, it is respectively: 25 parts of sodium hydroxide, 40 parts of boron nitride, 25 parts of epoxy silane coupling agent, 15 parts of dehydrated alcohol and 10 parts of Deionized water is selected and weighed;

[0032] Wherein in above-me...

Embodiment 2

[0044] A high thermal conductivity boron nitride powder filler, the formula includes: sodium hydroxide, boron nitride, epoxy silane coupling agent, absolute ethanol and deionized water, the mass percentage of each component is: 20 Parts of sodium hydroxide, 50 parts of boron nitride, 25 parts of epoxy silane coupling agent, 15 parts of absolute ethanol and 10 parts of deionized water.

[0045] A method for preparing a high thermal conductivity boron nitride powder filler, comprising the following steps: Step 1, material selection; Step 2, boron nitride treatment; Step 3, ultrasonic dispersion; Step 4, preheating and sintering; Step 5, cooling storage ;

[0046] Wherein in the above-mentioned step one, according to the content of each component, it is respectively: 20 parts of sodium hydroxide, 50 parts of boron nitride, 25 parts of epoxy silane coupling agent, 15 parts of dehydrated alcohol and 10 parts of Deionized water is selected and weighed;

[0047] Wherein in above-me...

Embodiment 3

[0059] A high thermal conductivity boron nitride powder filler, the formula includes: sodium hydroxide, boron nitride, epoxy silane coupling agent, absolute ethanol and deionized water, the mass percentage of each component is: 15 Parts of sodium hydroxide, 60 parts of boron nitride, 25 parts of epoxy silane coupling agent, 15 parts of absolute ethanol and 10 parts of deionized water.

[0060] A method for preparing a high thermal conductivity boron nitride powder filler, comprising the following steps: Step 1, material selection; Step 2, boron nitride treatment; Step 3, ultrasonic dispersion; Step 4, preheating and sintering; Step 5, cooling storage ;

[0061] Wherein in the above-mentioned step one, according to the content of each component, it is respectively: 15 parts of sodium hydroxide, 60 parts of boron nitride, 25 parts of epoxy silane coupling agent, 15 parts of dehydrated alcohol and 10 parts of Deionized water is selected and weighed;

[0062] Wherein in above-me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com