Patents

Literature

53results about How to "The process is simple and rigorous" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and device based on reverse engineering for automatically generating software documents

InactiveCN103336760ASimple configurationSimple processSpecial data processing applicationsSoftware design descriptionSoftware engineering

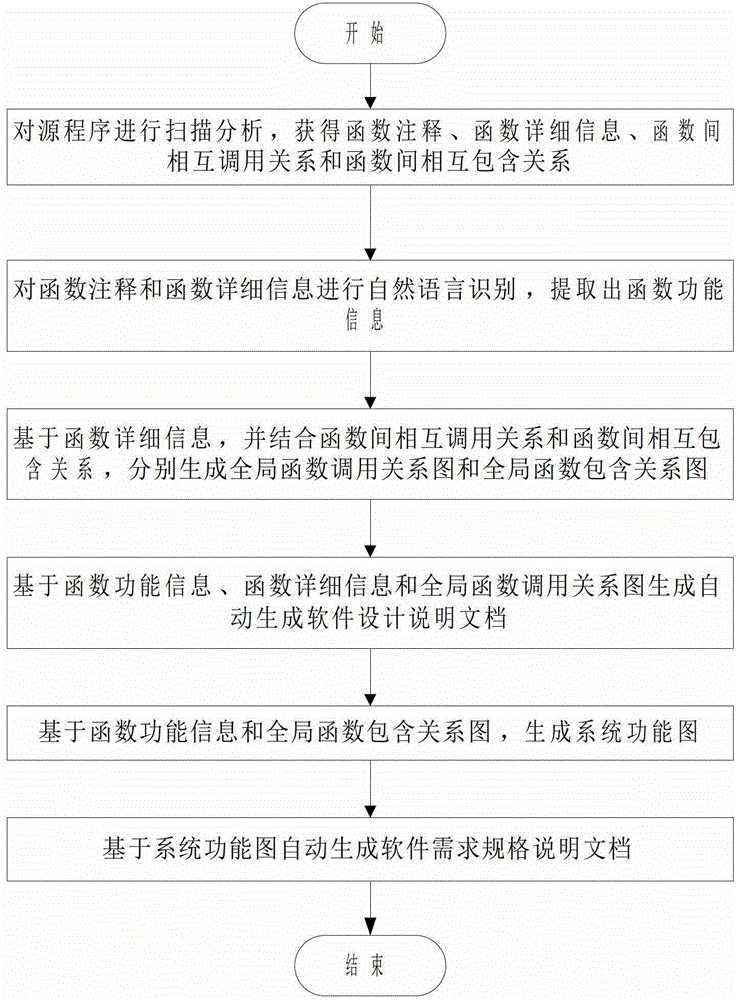

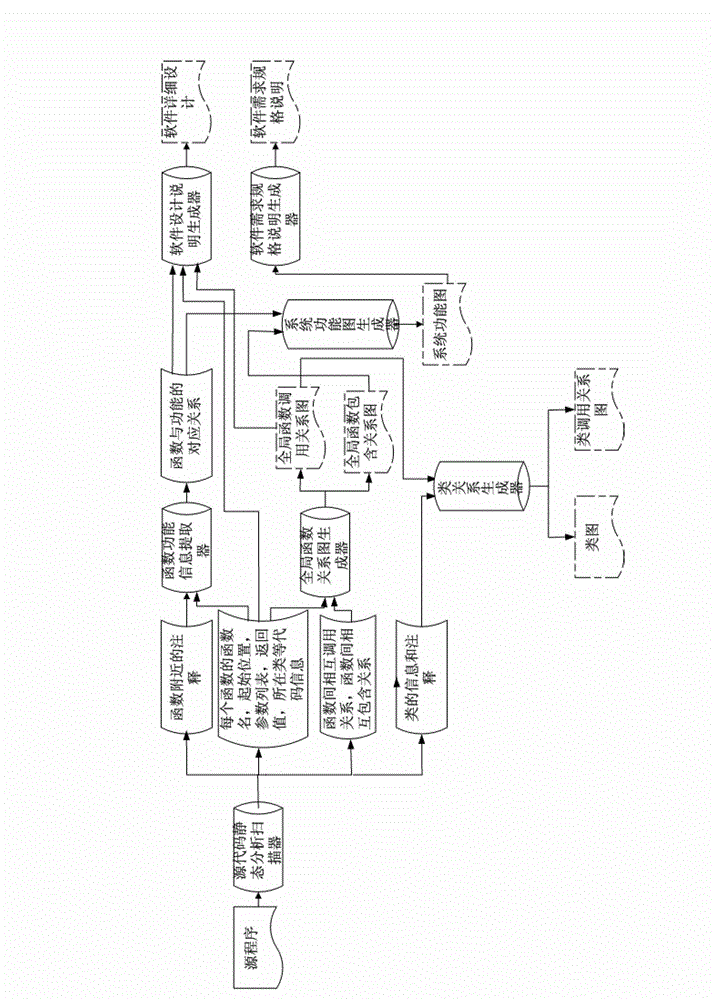

The invention relates to a method and device based on reverse engineering for automatically generating software documents. The method and device based on the reverse engineering for automatically generating the software documents comprises scanning source programs, obtaining function comments, function detail information and a mutual call relation and a mutual inclusion relation among functions, identifying and abstracting function information of functions through a natural language, generating a global function call relation graph and a global function inclusion relation graph respectively based on the function information of the functions and the mutual call relation and mutual inclusion relation among functions, automatically generating software design description documents based on the function information of the functions, the function detail information and the global function call relation graph, generating a system function graph based on the function information of the functions and the global function inclusion relation graph, and generating software requirement specification documents automatically based on the system function graph. According to the method and device based on the reverse engineering for automatically generating the software documents, the software requirement specification documents and the software design description documents are generated automatically, the reverse engineering from codes to documents is achieved, and the method and device based on the reverse engineering for automatically generating the software documents is wide in application and strong in adaptability.

Owner:BEIJING INFORMATION SCI & TECH UNIV +1

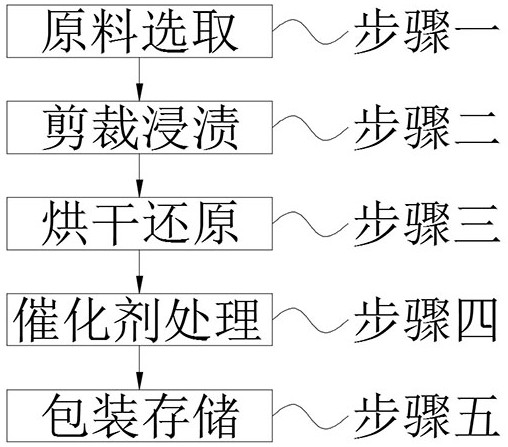

Fruity lollypop and processing technology

InactiveCN109221590AFully retain the flavorPreserve the flavorConfectionerySweetmeatsGlucose-Fructose SyrupFlavor

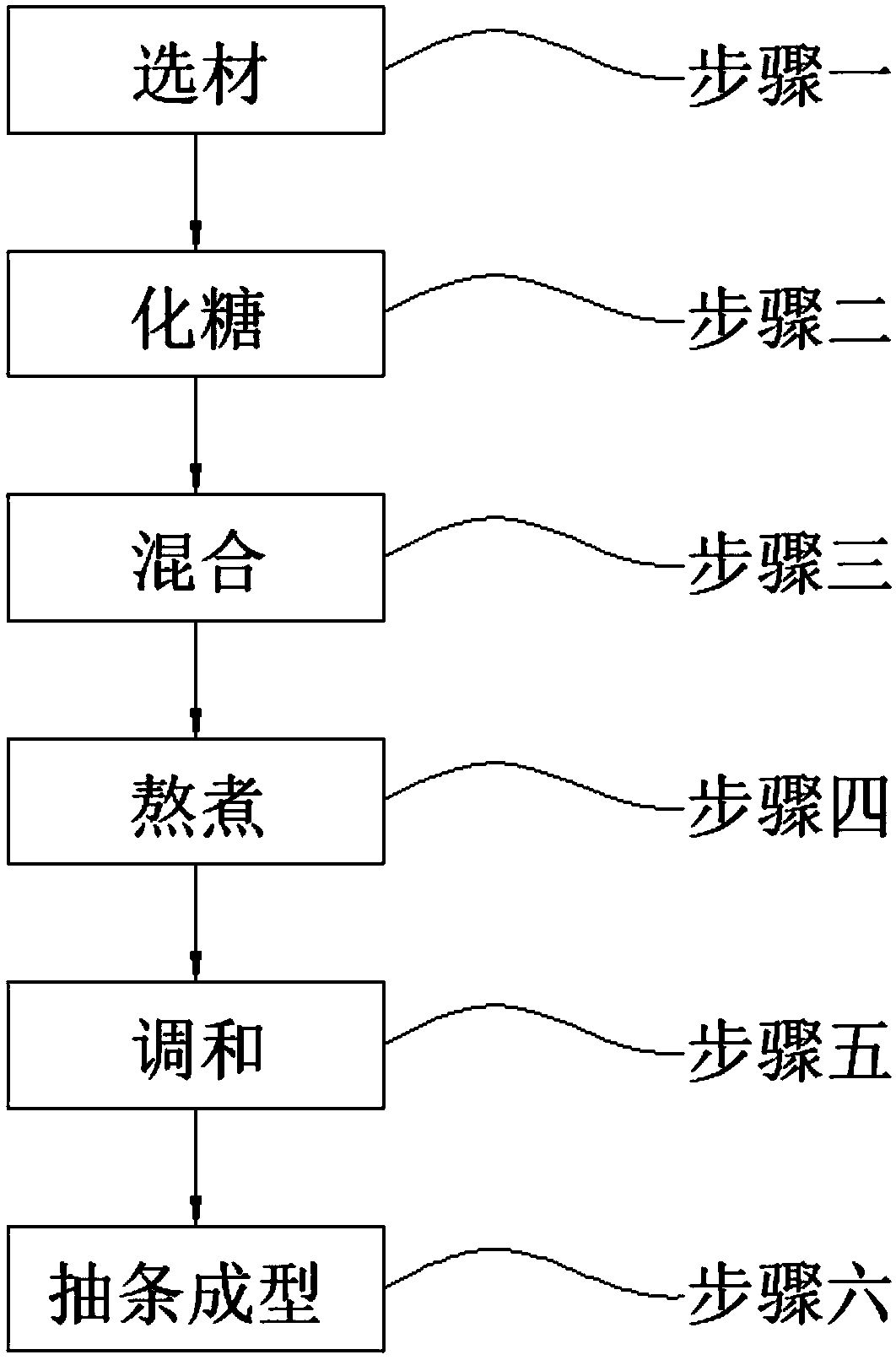

The invention discloses a fruity lollypop and a processing technology. A formula is prepared from the following components in percentage by mass: 40 to 50 percent of white granulated sugar, 20 to 30 percent of water, 10 to 20 percent of glucose syrup, 1 to 1.5 percent of citric acid, 3 to 5 percent of tea polyphenol, 6 to 8 percent of fruit juice concentrate and 0.2 to 0.3 percent of natural pigment, wherein the natural pigment is one of carotene, monascus color, carthamin and gardenia blue. The processing technology comprises the following steps: step one, material selecting; step two, sugardissolving; step three, mixing; step four, boiling; step five, blending; step six, sprouting and forming. According to the fruity lollypop disclosed by the invention, the components of the fruity lollypop adopt fruit puree, the original flavor of fruits is fully reserved, and the fruity lollypop is harmless to a human body; the technology of the fruity lollypop is simple and strict, the fruity lollypop is suitable for batch production, and compared with a lollypop made of a common essence additive, differentiation competitive advantage is formed.

Owner:东莞亿智食品有限公司

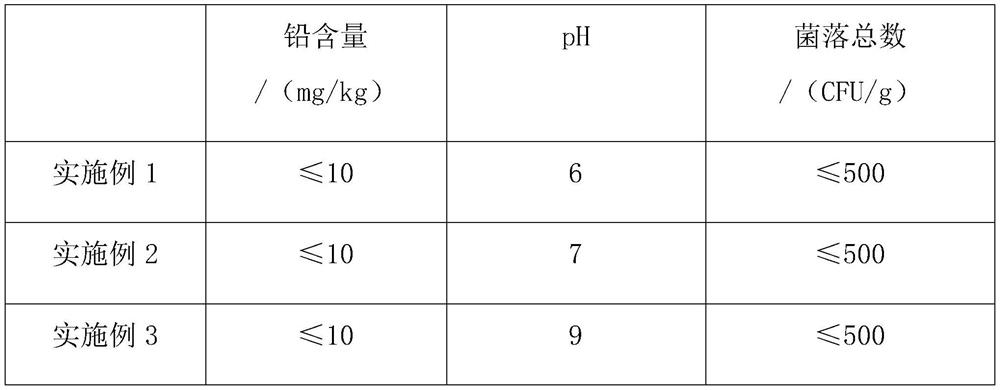

Double-surface-smooth ultra-thin electrolytic copper foil for lithium battery and preparation method thereof

InactiveCN110257863AQuality improvementEasy to manufactureElectroforming processesElectrolysisSilanes

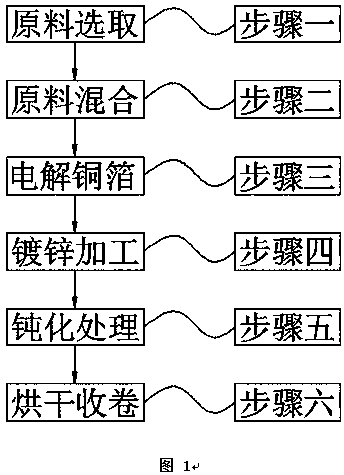

The invention discloses a double-surface-smooth ultra-thin electrolytic copper foil for a lithium battery and a preparation method thereof. The formula of the electrolytic copper foil comprises pure water, a copper raw material, sulfuric acid, chromate, hydrogen peroxide, silane, an initiator, a resin base material, a catalyst and a coupling agent, each component is in percentage by mass of 16% of the pure water, 20% of the copper raw material, 15% of the sulfuric acid, 10% of the chromate, 4% of the hydrogen peroxide, 20% of the silane, 3% of the initiator, 10% of the resin base material, 1% of the catalyst and 1% of the coupling agent; the preparation method comprises the following steps of Step 1, selecting raw material; Step 2, mixing raw material; Step 3, electrolyzing copper foil; Step 4, carrying out galvanizing; Step 5, carrying out passivation treatment; and Step 6, drying and rolling the electrolytic copper foil. According to the preparation method, the copper raw material is soaked in the hydrogen peroxide, so that the time of the copper raw material in the sulfuric acid is greatly reduced, and the preparation of copper sulfate solution is facilitated; and an electrolytic cathode roller and an anode seat adopt pure titanium raw materials and lead-antimony alloy correspondingly, so that the cathode roller and the anode base are avoided to react with copper sulfate to generate impurities, and the quality of the copper foil is improved.

Owner:贵州中鼎高精铜箔制造有限公司

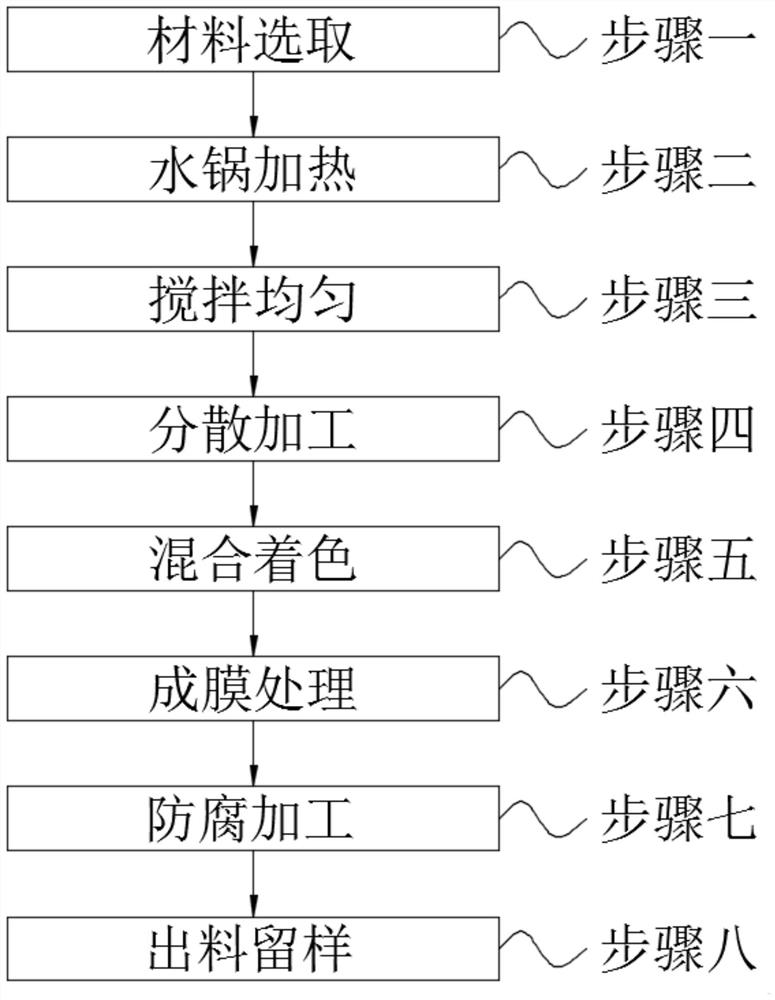

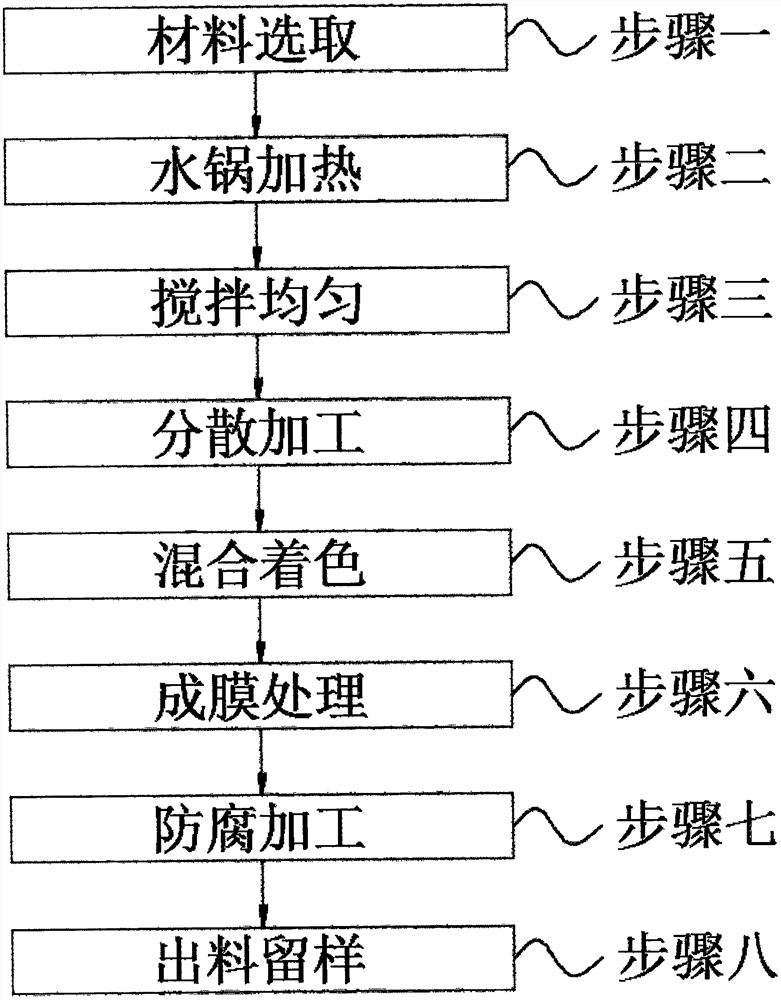

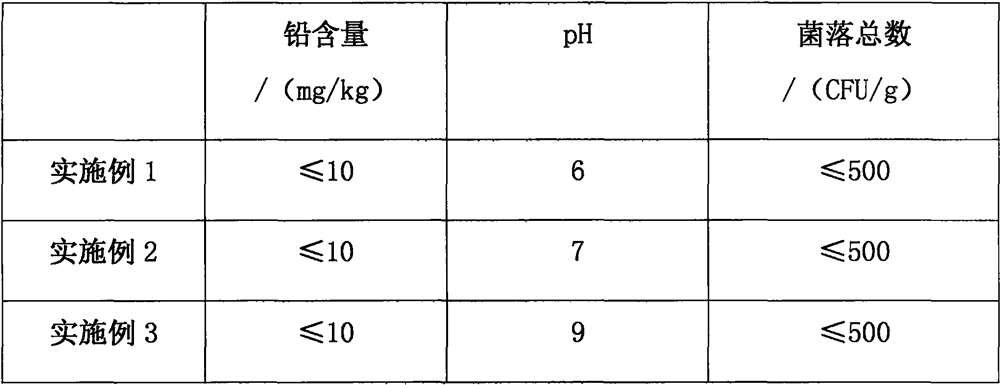

Viscous liquid eyeliner and production process

InactiveCN112451417AStable physical and chemical propertiesThe process is simple and rigorousCosmetic preparationsMake-upSolventHuman health

The invention discloses a viscous liquid eyeliner and a production process. A formula comprises the following components in parts by mass: 15-25 parts of a solvent, 40-60 parts of xanthan gum, 20-30 parts of propylene glycol, 20-30 parts of an acrylic acid (acrylate) copolymer, 5-10 parts of a colorant and 10-20 parts of a preservative. The production process comprises the following steps: step 1,material selection; step 2, heating in a water pot; step 3, uniform stirring; step 4, dispersion processing; step 5, mixing and coloring; step 6, film forming treatment; step 7, preservative processing; and step 8, discharging and sample reserving. The viscous liquid eyeliner is safe and reliable, the physicochemical properties of the raw materials adopted by the formula are stable, and accordingto the known chemical interaction, after the raw materials are mixed, no risky substance is generated, no harm is caused to human health, and the use by users is facilitated; and the raw materials are cheap and low in cost, and processing and production are facilitated.

Owner:袁明斌

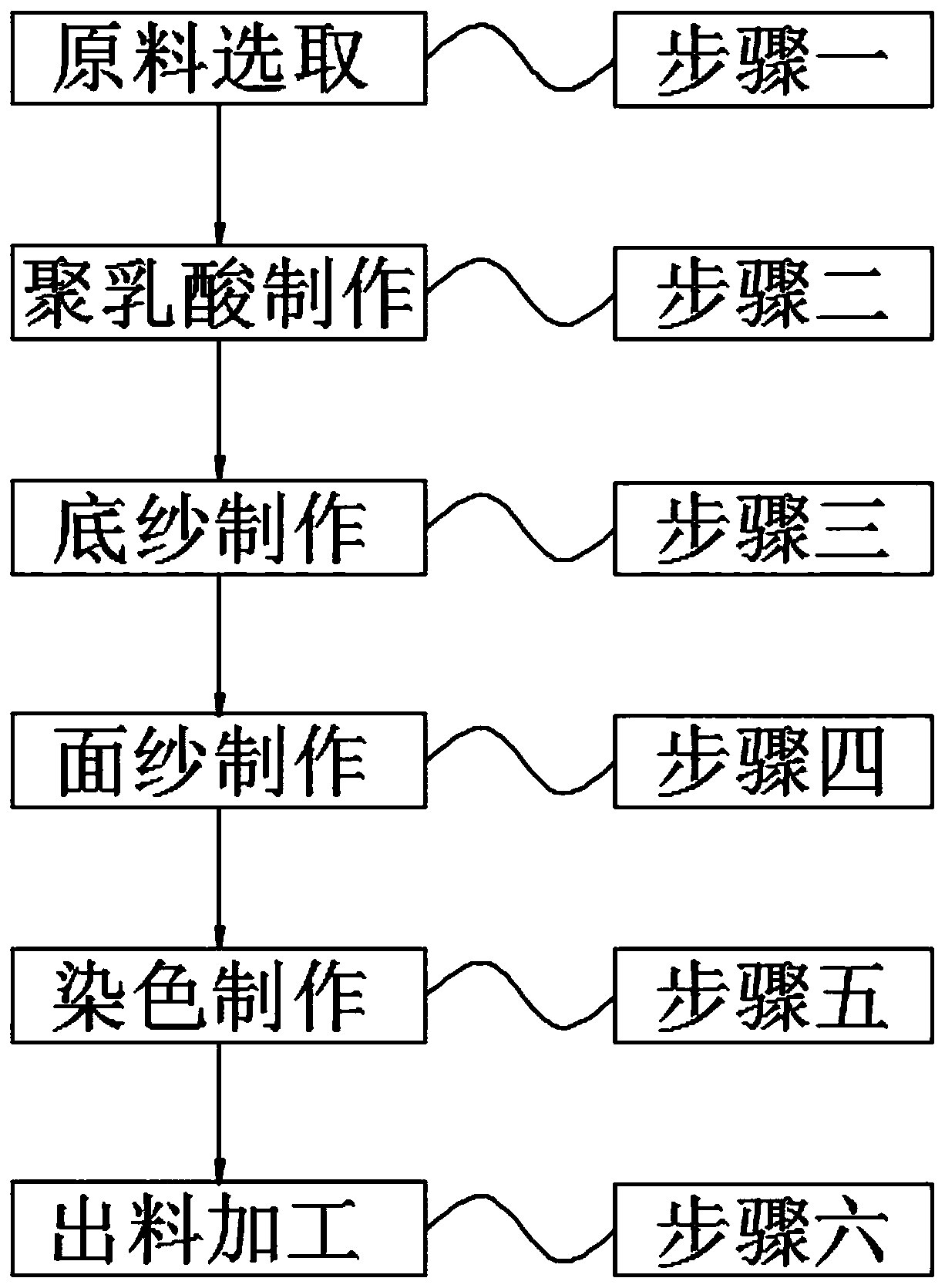

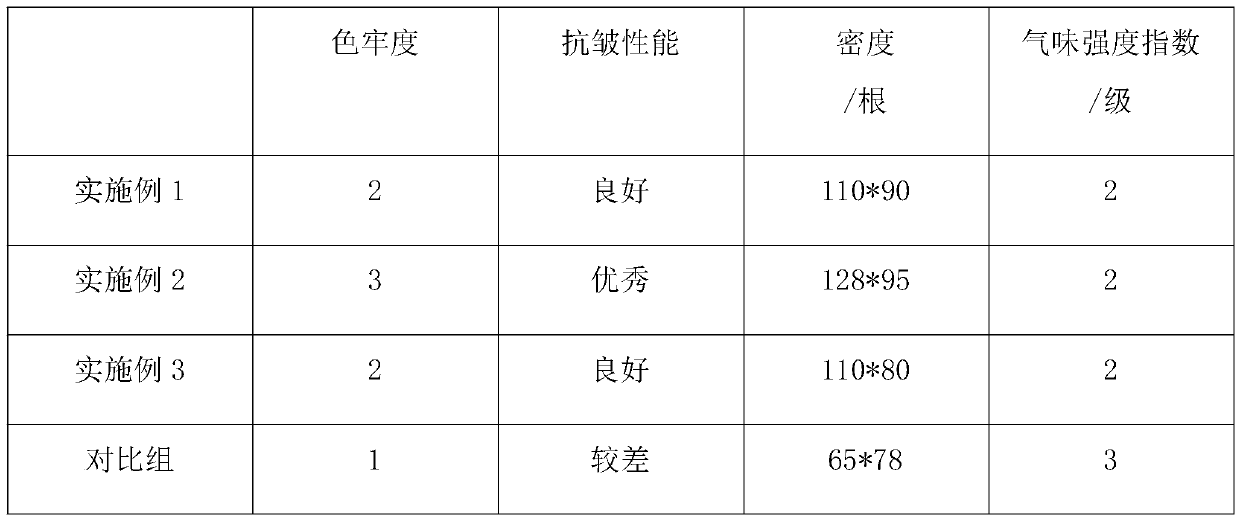

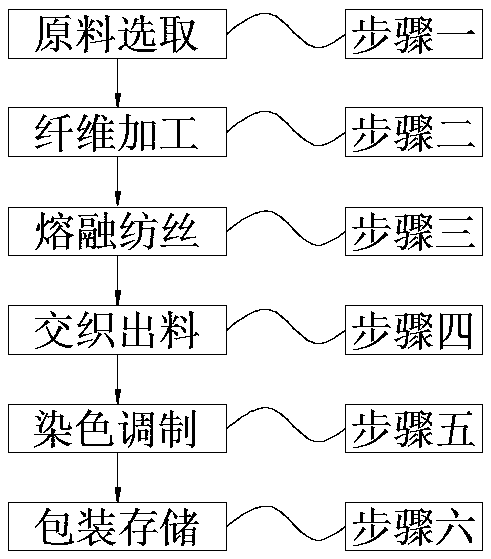

Flax interwoven fabric with built-in polylactic acid material and processing technology thereof

InactiveCN109914010AEnvironmental protection is goodSmall smellDyeing processWoven fabricsMilk proteinMonomer

The invention discloses a flax interwoven fabric with a built-in polylactic acid material and a processing technology thereof. The fabric is prepared from by mass, 15-25% of lactic acid monomers, 25-35% of flax, 3-8% of polyamide fiber, 10-20% of viscose filament yarn, 15-25% of polyester yarn, 5-10% of milk protein fiber, 2-5% of a dehydrating agent, 1-3% of a catalyst and 1-3% of a dyeing agent.The preparation technology comprises the steps of 1 selecting raw materials, 2 manufacturing polylactic acid, 3 manufacturing ground yarn, 4 manufacturing surface yarn, 5 dyeing and manufacturing and6 discharging and processing. The fabric is safe and reliable, the fabric is made of polylactic acid, the polylactic acid has the excellent environment-friendly performance, meanwhile, the wrinkle resistance of the flax interwoven fabric with the built-in polylactic acid material is improved, and the appearance is attractive.

Owner:JIANGSU MINGYUAN TEXTILE

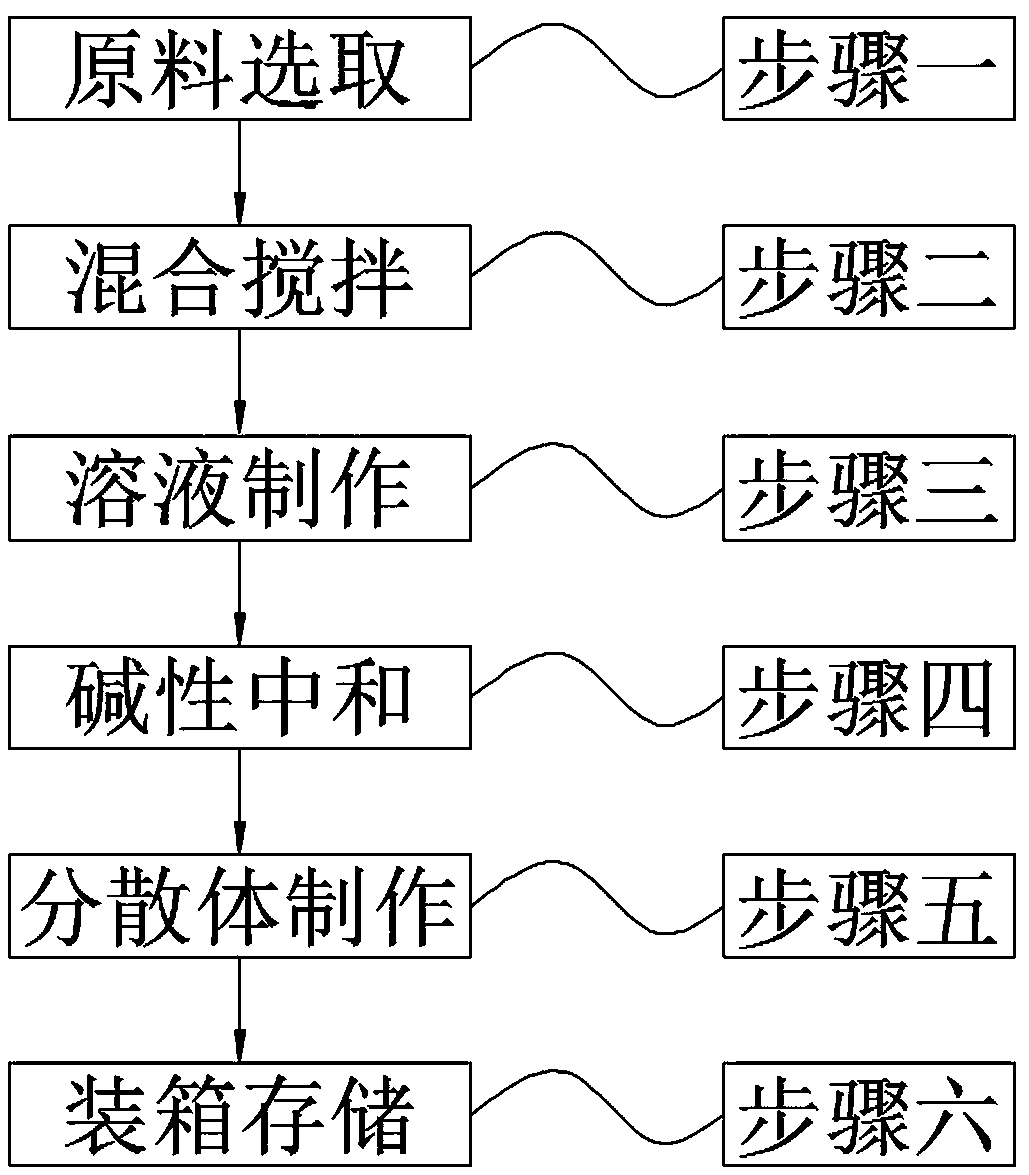

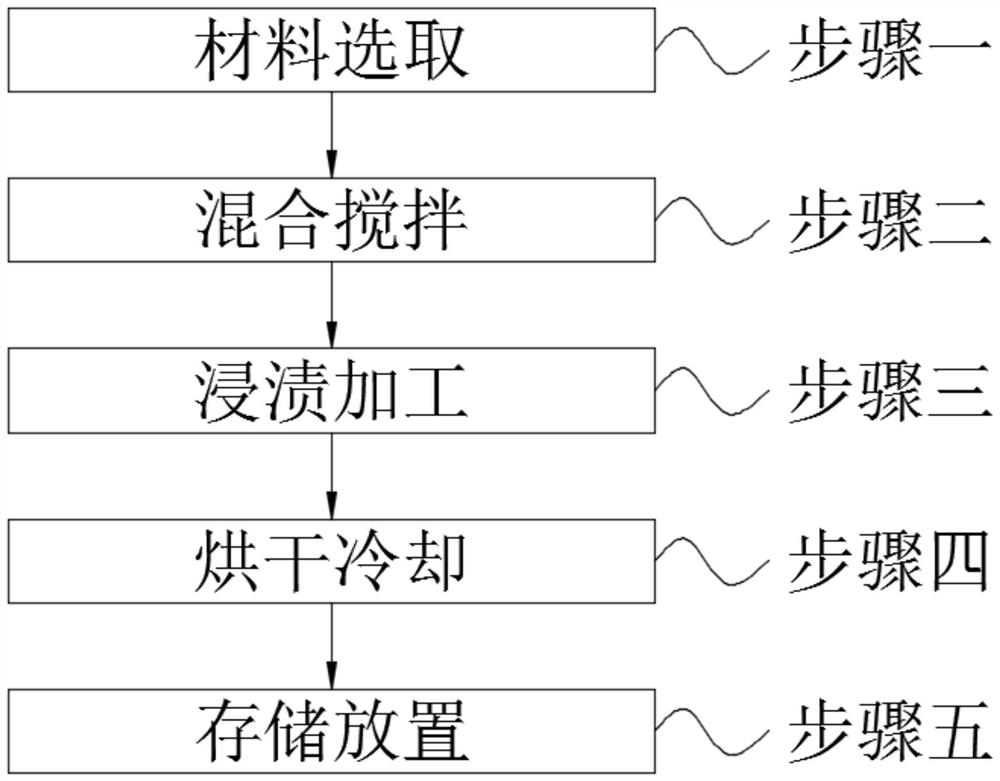

Water-based hydroxy acrylic acid dispersion and preparation method thereof

The invention discloses a water-based hydroxy acrylic acid dispersion and a preparation method thereof. The formula comprises: by mass,15 to 25 parts of an acrylic acid polymerization monomer, 20 to 30 parts of an organic solvent, 15 to 25 parts of deionized water, 10 to 20 parts of a chain regulator, 2 to 4 parts of a cross-linking agent, 10 to 20 parts of an alkaline neutralizer and 1 to 3 partsof an initiator. The preparation method comprises the following steps: 1, raw material selection, 2, mixing and stirring, 3, solution preparation, 4, alkaline neutralization, 5, dispersion preparation, and 6, encasement and storage. The dispersion is safe and reliable, does not contain a solvent, utilizes hydroxyl radical polymerization, and has the advantages of high glossiness, good weather resistance, high hardness, good water resistance, good chemical resistance and the like. The preparation method is simple and rigorous in process, cheap in raw materials, low in cost and convenient to process.

Owner:QINGYUAN YAKOO CHEM CO LTD

Tissue culture propagation method of endangered rare plant tetraena mongolica

ActiveCN113207693AEnsure a sterile environmentIncrease production capacityAfforestationHorticulture methodsBiotechnologySterile environment

The invention belongs to the technical field of plant asexual propagation, and discloses a tissue culture propagation method of an endangered rare plant tetraena mongolica. Tissue culture is intensively embodied in collection and pretreatment of an explant of the tetraaceae mongolian and the completion part of each treatment stage of the tetraaceae mongolian. A tissue culture technology is applied, and annual tetraena mongolica plants are directly induced to root for propagation. The annual new branches are taken as explants, and washing with running water is conducted to remove attachments such as dust and the like on the surfaces of the explants; and a cleaning agent is adopted to disinfect and sterilize the surface of the explants. The sterilizing agent is used for disinfecting and sterilizing the explants, the sterile environment of the treated explants is guaranteed through secondary flushing of sterile water, and the sterilizing agent is matched with the optimal culture medium to complete tissue culture of the tetraena mongolica. According to the culture mode, the technical bottleneck of artificial breeding and cultivation of the tetraena mongolica is broken through, and artificial rapid breeding and large-scale production and application of endangered desert plants are achieved. A large number of tetraena mongolica plants are obtained through a tissue culture asexual propagation means, artificial propagation of tetraena mongolica is achieved, and basic conditions are provided for continuation and expansion of populations.

Owner:包头市园林科研所

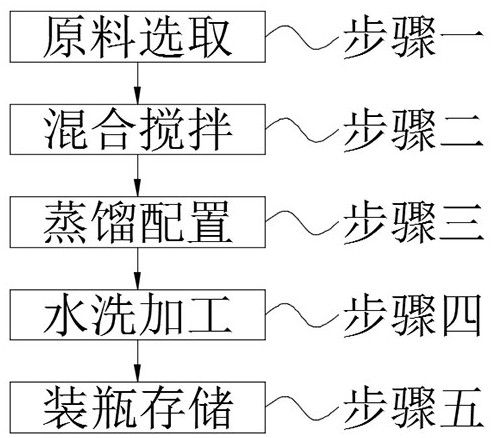

Formula of working solution in hydrogen peroxide production process

InactiveCN111908429AFast oxidationIncreased rate of hydrogen productionPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesAnthraquinonesEthylic acid

The invention discloses a formula of a working solution in a hydrogen peroxide production process, which comprises the following components in percentage by mass: tetrahydronaphthalene, a carrier, a solvent, 2-methylcyclohexyl acetate, sulfurized oleic acid, saline water and triethanolamine, according to the following mass percentage ratio: 15-25% of tetrahydronaphthalene, 20-35% of a carrier, 15-25% of a solvent, 10-20% of 2-methylcyclohexyl acetate, 3-7% of sulfurized oleic acid, 10-20% of saline water and 6-12% of triethanolamine. The working solution is safe and reliable, and is prepared by mixing and processing a carrier formed by mixing 2-ethyl anthraquinone and tetrahydro-2-ethyl anthraquinone and a mixed solvent of trioctyl phosphate and heavy aromatics, the performance is more stable, the oxidation speed of hydrogen peroxide is greatly increased, the hydrogen production rate of hydrogen peroxide is increased and loss of theworking solution is reduced. In addition, by means ofthe distillation and continuous washing processing mode, heavy aromatics in the solvent are prevented from generation and side reactions are reduced; the method is simple and rigorous in process, cheap in raw materials, low in cost and beneficial to processing and production.

Owner:JIANGSU LEE & MAN CHEM

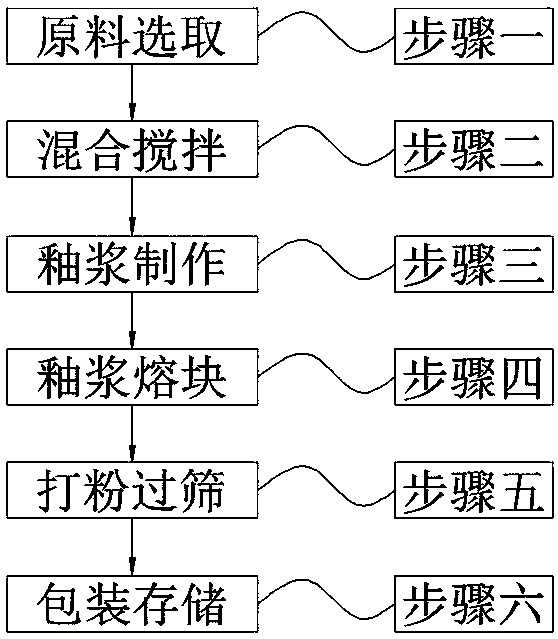

Preparation method of self-cleaning external gray glaze

The invention discloses a preparation method of self-cleaning external gray glaze. The formula comprises lead oxide, silicon dioxide, aluminum oxide, clay, borax, calcium oxide, magnesium oxide, porcelain powder, an opacifier and a strong fluxing agent. The preparation process comprises the following steps: step 1, selecting raw materials; step 2, mixing and stirring the raw materials; step 3, preparing glaze slip; step 4, fritting the glaze slip; step 5, powdering and sieving; and step 6, packaging and storing. The method is safe and reliable. Silicon dioxide, aluminum oxide and clay are usedas raw materials, borax and porcelain powder are scattered in, and the fired glaze is smooth, high in whiteness and good in brightness. The strong fluxing agent is adopted for sintering, the chemicalcorrosion resistance is high, wear resistance is extremely high, and certain self-cleaning performance is achieved. The process is simple and rigorous, other expensive gray glaze production processescan be replaced, the effect is remarkable, the raw materials are cheap, the cost is low, machining is convenient, the production cost is greatly saved, and machining and production are facilitated.

Owner:湖南高强电瓷电器有限公司

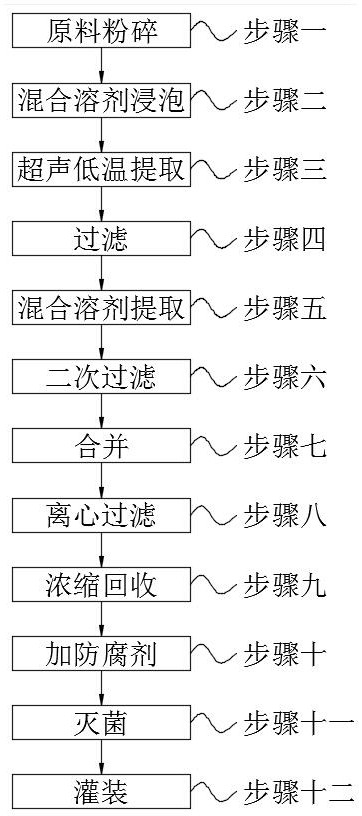

Process for extracting effective components of cosmetic extracting solution

InactiveCN112006957AHigh purityEasy to operateCosmetic preparationsToilet preparationsPreservativeProcess engineering

The invention discloses a process for extracting effective components of a cosmetic extracting solution. The extraction process comprises the following steps: step 1, crushing raw materials; step 2, soaking the materials in a mixed solvent; step 3, performing ultrasonic low-temperature extraction; step 4, performing filtering; step 5, performing extracting with a mixed solvent; step 6, performingsecondary filtration; step 7, performing merging; step 8, performing centrifugal filtration; step 9, performing concentrating and recycling; step 10, adding a preservative; step 11, performing sterilizing; and step 12, performing filling. The process for extracting effective components of a cosmetic extracting solution is simple in operation and adopts fructus cnidii as raw material, 3-butanedioland an ethanol solvent are added for ultrasonic low-temperature extraction, and filtering and concentrating are conducted to obtain effective components of the cosmetic extracting solution; the process is convenient and high in extraction efficiency, the extracted effective components of the cosmetic extracting solution do not contain impurities, the purity of the effective components of the cosmetic extracting solution is improved, raw materials are cheap, cost is low, processing is convenient, production cost is greatly saved, and processing and production are facilitated.

Owner:赣州佰珍堂香料有限公司

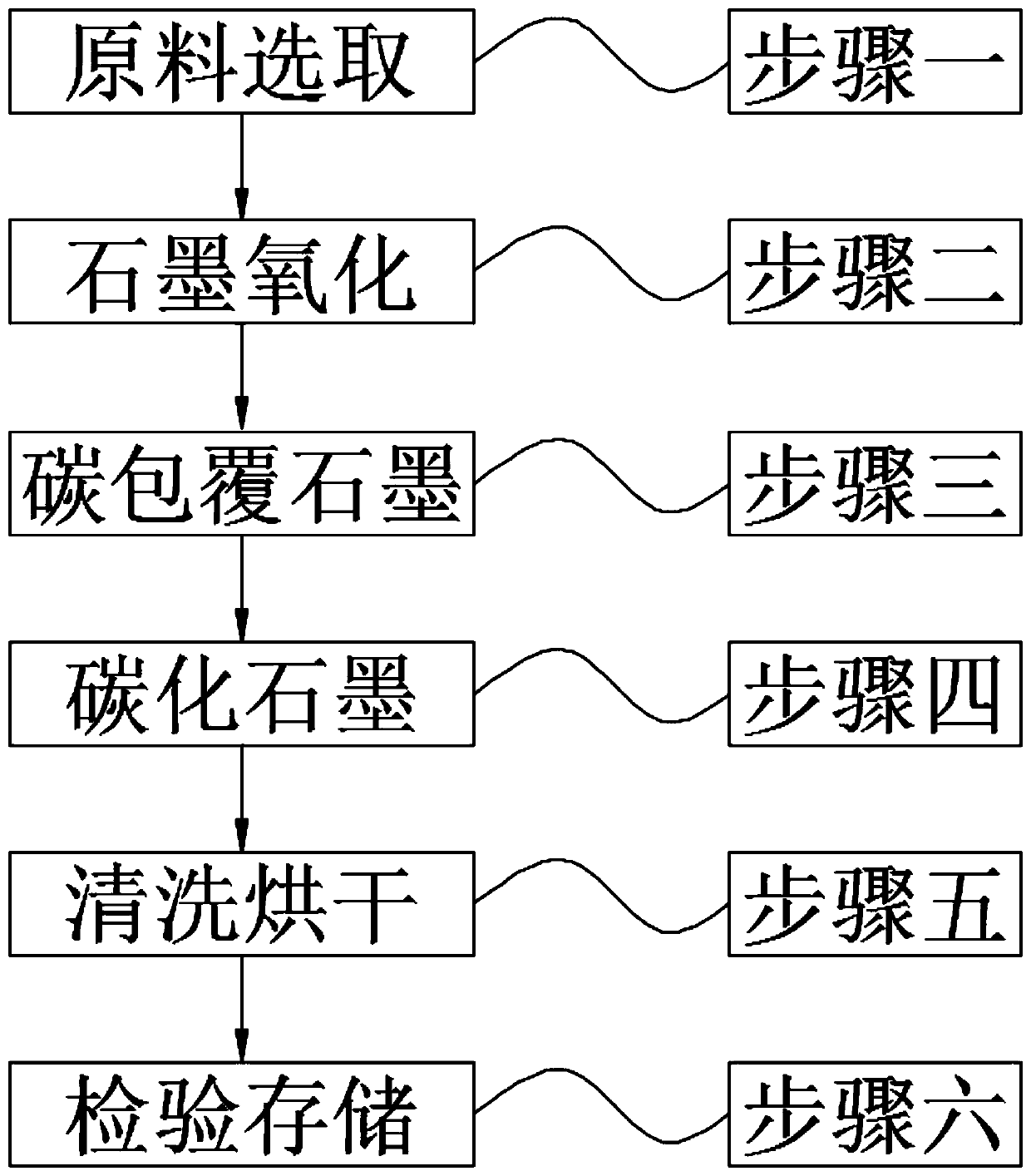

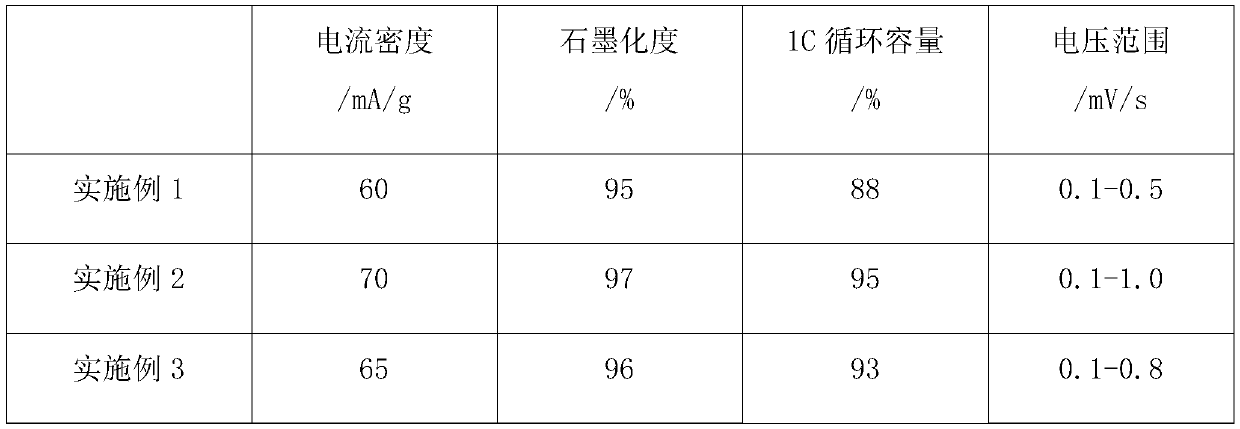

Preparation method of carbon-coated graphite negative electrode material

InactiveCN110642237AImprove electrochemical performanceReduce defectsGraphiteCell electrodesEpoxyPtru catalyst

The invention discloses a preparation method of a carbon-coated graphite negative electrode material. The carbon-coated graphite negative electrode material comprises graphite, graphene, ionic liquid,epoxy resin, polyvinylidene fluoride, ethanol, a pickling mixed solution, benzenediol, a catalyst and an initiator, and the mass percentages of the components are as the follows: 15-25% of graphite,20-30% of graphene, 15-25% of ionic liquid, 10-20% of epoxy resin, 2-4% of polyvinylidene fluoride, 10-20% of ethanol, 1-3% of the pickling mixed solution, 5-10% of benzenediol, 0.5-1% of the catalystand 0.5-1% of the initiator. The preparation method comprises the following steps: step 1, selecting raw materials; step 2, oxidizing graphite; step 3, coating the graphite with carbon; step 4, carbonizing the graphite; step 5, carrying out cleaning and drying; and step 6, carrying out inspecting and storing. The preparation method has a simple and rigorous process, and can replace other expensive preparation process of carbon-coated graphite negative electrode materials, and the effect is obvious. Raw materials are cheap and have low cost, and processing is convenient, so that production cost is greatly saved, and processing and production are facilitated.

Owner:DONGGUAN KAIJIN NEW ENERGY TECH

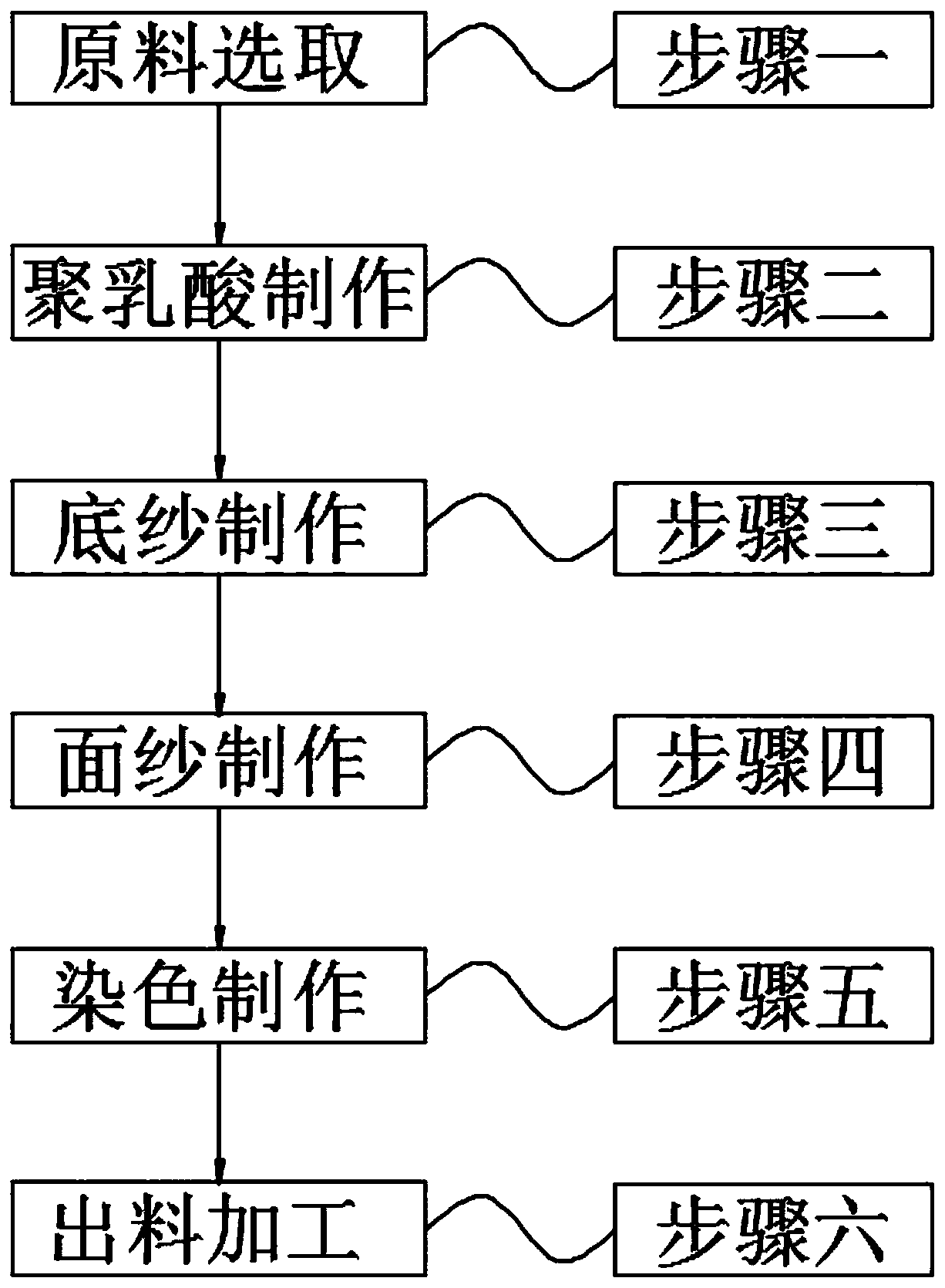

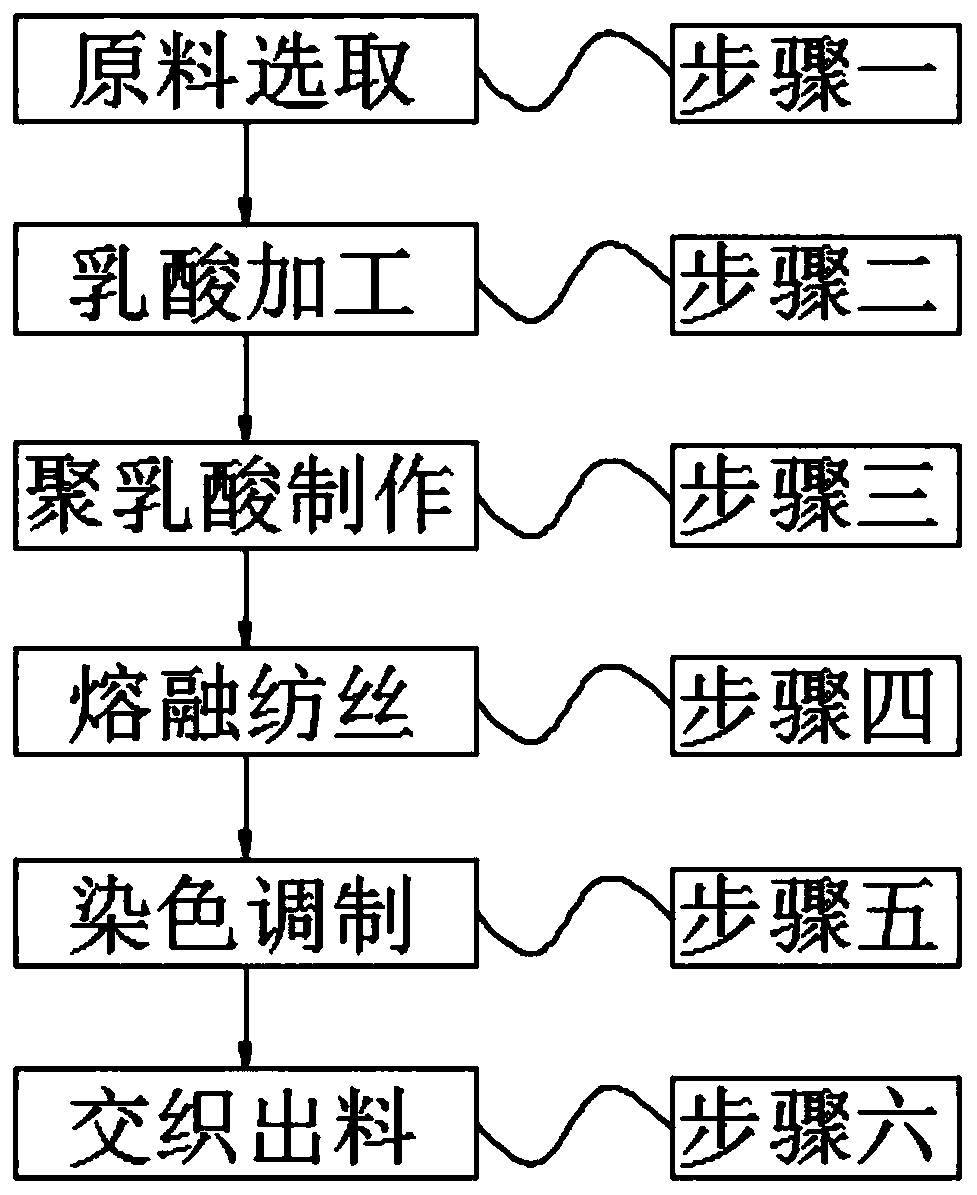

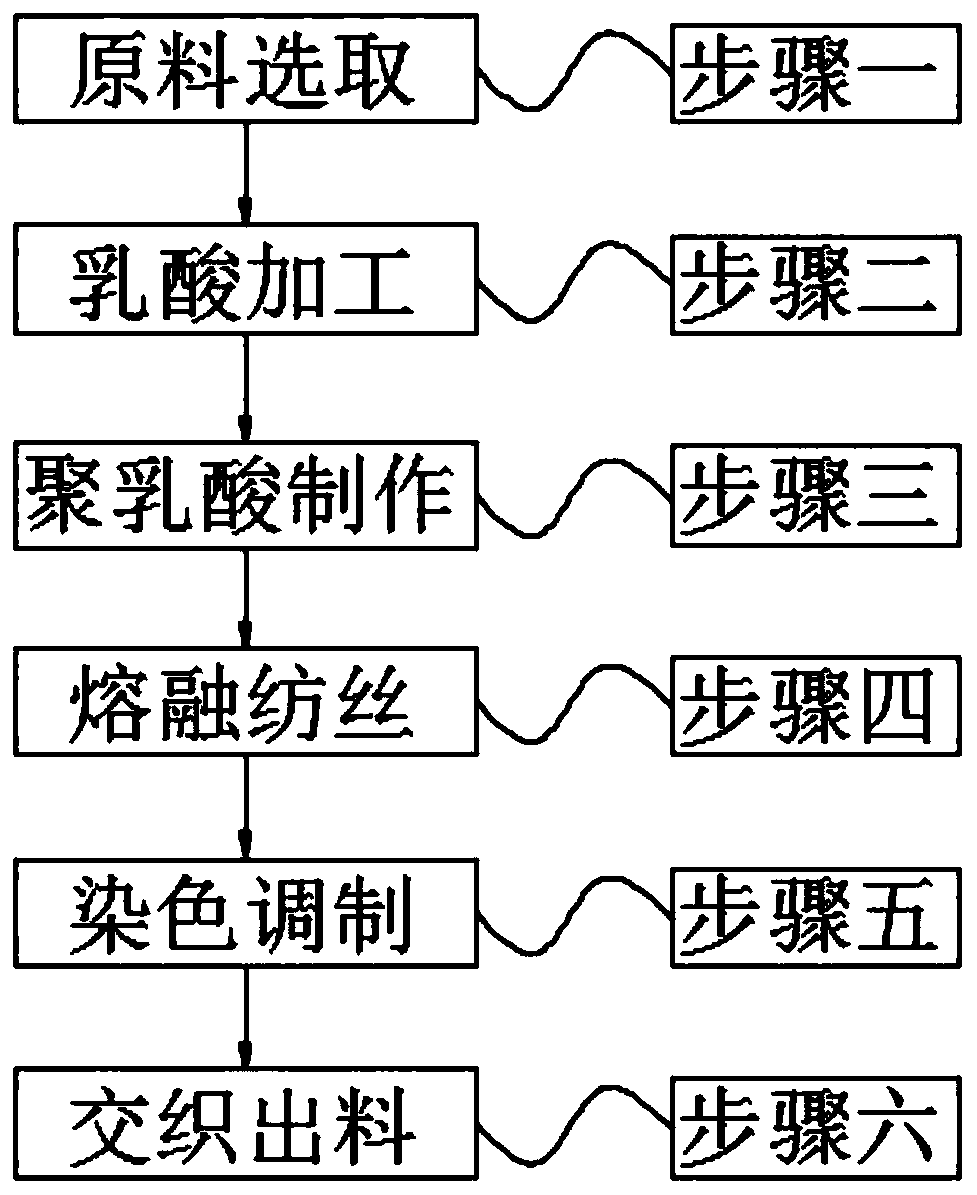

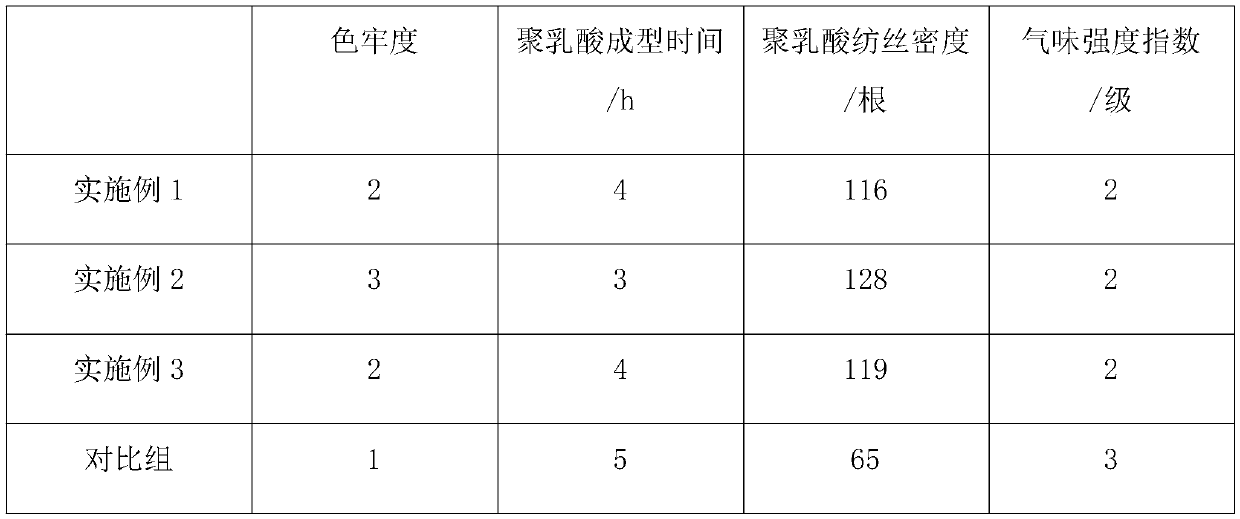

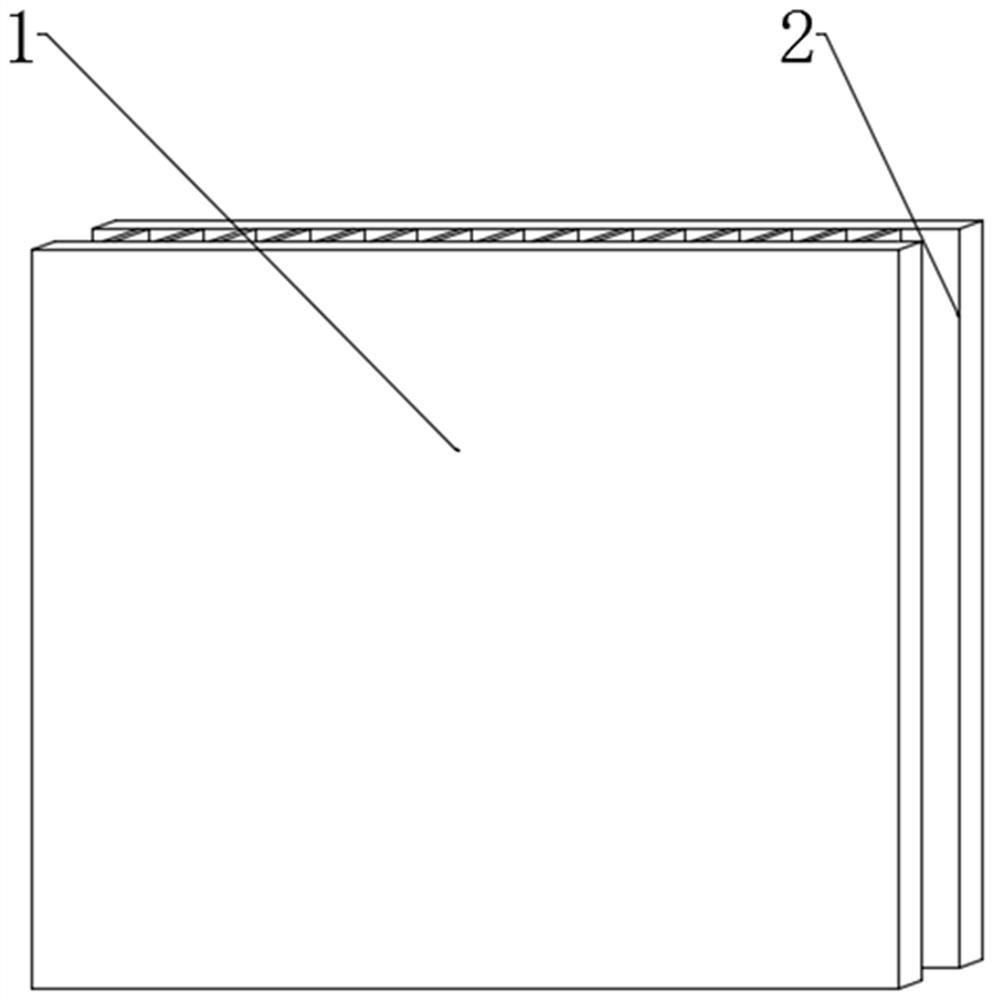

Polylactic acid based cotton interwoven fabric and processing method thereof

InactiveCN110004565APromote environmental protectionSmall smellMelt spinning methodsWoven fabricsPolyesterCellulose

The invention discloses a polylactic acid based cotton interwoven fabric and a processing method thereof. The polylactic acid based cotton interwoven fabric is prepared from, by mass, 25-35% of starch, 15-25% of cellulose, 3-8% of calcium carbonate, 10-20% of lime milk, 15-25% of polyester fibers, 5-10% of acetone, 2-5% of a dehydrating agent, 1-3% of a catalyst and 1-3% of a coloring agent according to a formula. A preparation process includes: step one, raw material selection; step two, lactic acid processing; step three, polylactic acid preparation; step four, melt spinning; step five, dyepreparation; step six, interweaving and discharging. The polylactic acid based cotton interwoven fabric and the processing method thereof have advantages that safety and reliability are realized, polylactic acid is obtained by starch fermentation and lactide ring-opening polymerization, lime milk is added for accelerating reaction to obtain polylactic acid with extremely high relative molecular weight, high polylactic acid spinning density, low manufacturing cost and cheapness of raw materials are realized, and production cost is greatly saved.

Owner:JIANGSU MINGYUAN TEXTILE

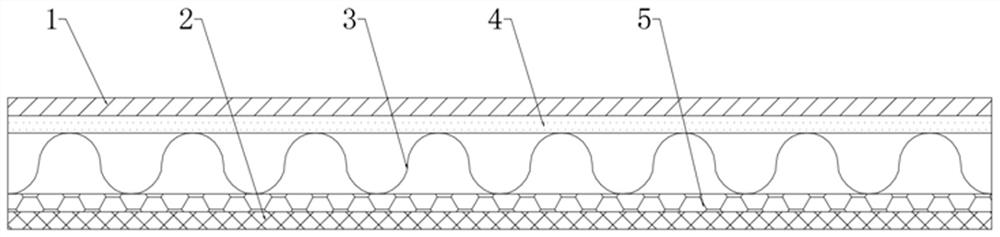

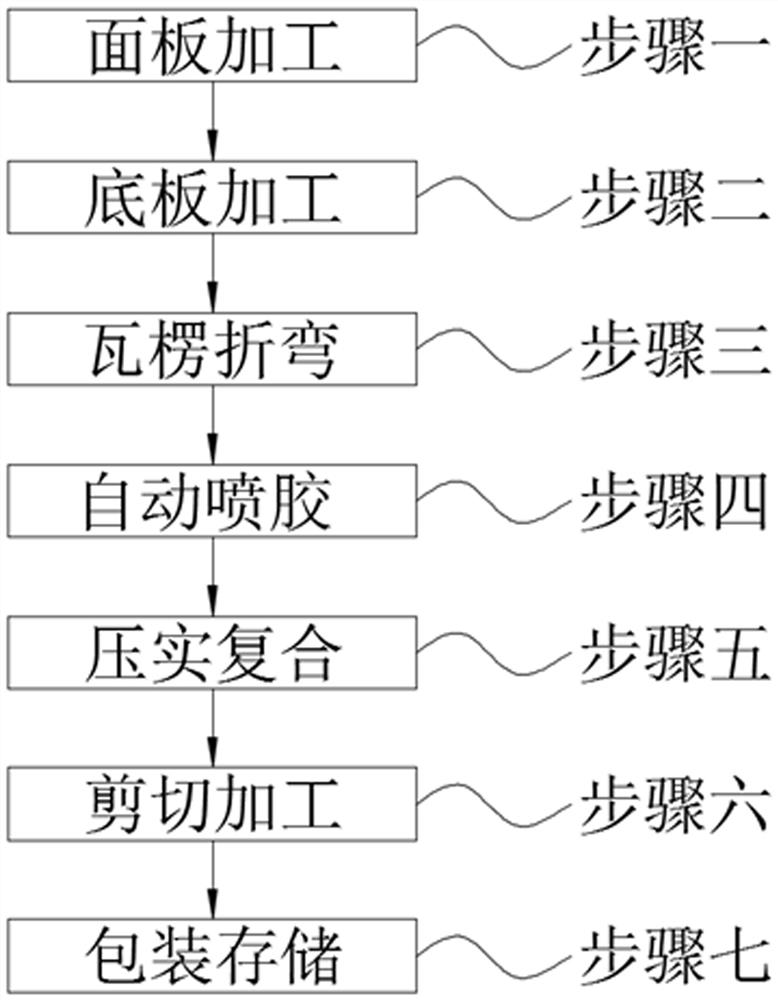

Aluminum corrugated board and processing method

PendingCN113815277AImprove adhesion strengthImprove flatnessRoof covering using slabs/sheetsConstruction materialPolyesterPolymer science

The invention discloses an aluminum corrugated board and a processing method, the aluminum corrugated board comprises a fluorocarbon coated aluminum panel, a polyester coated aluminum bottom plate, an aluminum corrugated core, a first viscous adhesive film layer and a second viscous adhesive film layer, the polyester coated aluminum bottom plate is arranged at the bottom of the panel, the second viscous adhesive film layer is adhered to the top of the polyester coated aluminum bottom plate, the first viscous adhesive film layer is adhered to the bottom of the fluorocarbon coated aluminum panel, and the aluminum corrugated core is arranged at the center of the fluorocarbon coated aluminum panel and the center of the polyester coated aluminum bottom plate, the fluorocarbon coated aluminum panel, the polyester coated aluminum bottom plate and the aluminum corrugated core are adopted as raw materials and are compounded and compacted under the high-temperature condition to form the aluminum corrugated board, a traditional direct bonding processing mode is abandoned, the bonding surfaces of the aluminum corrugated core, the fluorocarbon coated aluminum panel and the polyester coated aluminum bottom plate are cambered surfaces, so that the bonding surfaces are larger, the bonding strength is higher, and in addition, the aluminum corrugated board is light in weight, environment-friendly, sound-proof, heat-insulating, good in rigidity and higher in flatness.

Owner:金言实业集团有限公司

Viscous liquid eyeliner and production process

PendingCN113350209AStable physical and chemical propertiesEasy to useCosmetic preparationsMake-upViscous liquidHuman health

The invention discloses a viscous liquid eyeliner and a production process. The formula of the viscous liquid eyeliner comprises the following components in parts by mass: 15 to 25 parts of solvent, 40 to 60 parts of xanthan gum, 20 to 30 parts of propylene glycol, 20 to 30 parts of acrylic acid (ester) copolymer, 5 to 10 parts of colorant and 10 to 20 parts of preservative. The production process comprises the following steps: step 1, selecting materials; step 2, heating a water pot; step 3, performing uniform stirring; step 4, performing dispersion processing; step 5, performing mixing and coloring; step 6, performing film forming treatment; step 7, performing preservative processing; and step 8, performing discharging and reserving samples. The viscous liquid eyeliner disclosed by the invention is safe and reliable; the raw materials adopted by the formula are stable in physical and chemical properties; according to known chemical interaction, after the raw materials are mixed, no risk substance is generated, no harm is caused to human health, and the viscous liquid eyeliner is beneficial to use of a user; and moreover, the raw materials of the viscous liquid eyeliner disclosed by the invention are cheap and low in cost, and processing and production are facilitated.

Owner:袁明斌

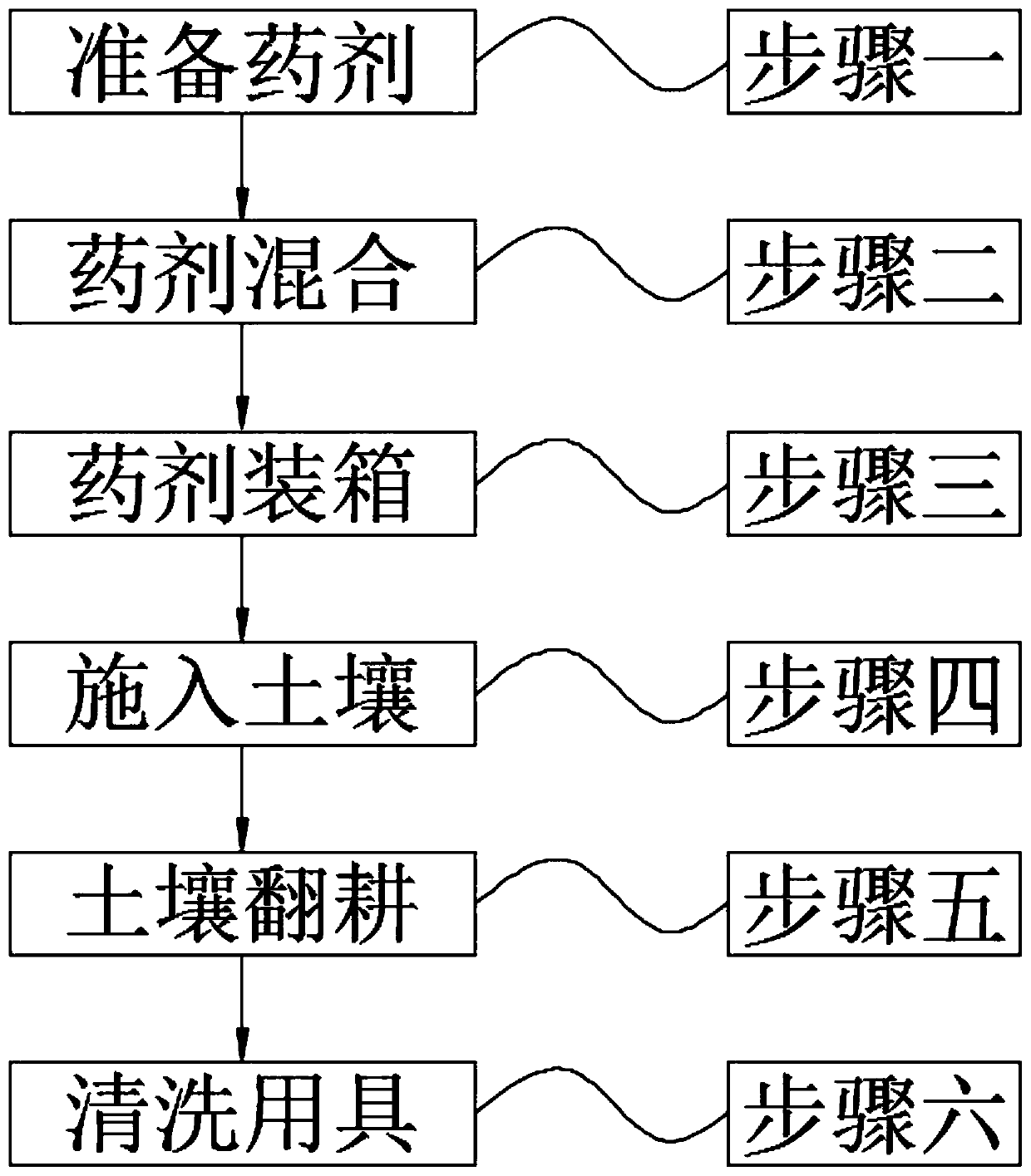

Iron and steel enterprise contaminated soil remediation agent and use method thereof

InactiveCN110511084AReduce CuLower HgSuperphosphatesContaminated soil reclamationSodium BentoniteDefoaming Agents

The invention discloses an iron and steel enterprise contaminated soil remediation agent and a use method thereof. The formula comprises the following components by mass percentage: 15-25% of quick lime, 20-30% of bentonite, 15-25% of calcium superphosphate, 10-20% of a calcium magnesium phosphate fertilizer, 2-4% of ground phosphate rock, 10-20% of biomass charcoal, 1-3% of an organic fertilizer,5-10% of corn straw, 0.5-1% of a catalyst and 0.5-1% of a defoaming agent. The use method includes: step 1, reagent preparation; step 2, reagent mixing; step 3, reagent cartonning; step 4, application into soil; step 5, soil plowing; and step 6, appliance cleaning. According to the invention, the soil remediation agent is safe and reliable, the process is simple and rigorous, can replace other expensive soil remediation agent production processes, the effect is remarkable, the raw materials are cheap and the cost is low, and the production cost is greatly saved, thus facilitating processing and production.

Owner:上海中新国源环保集团有限公司

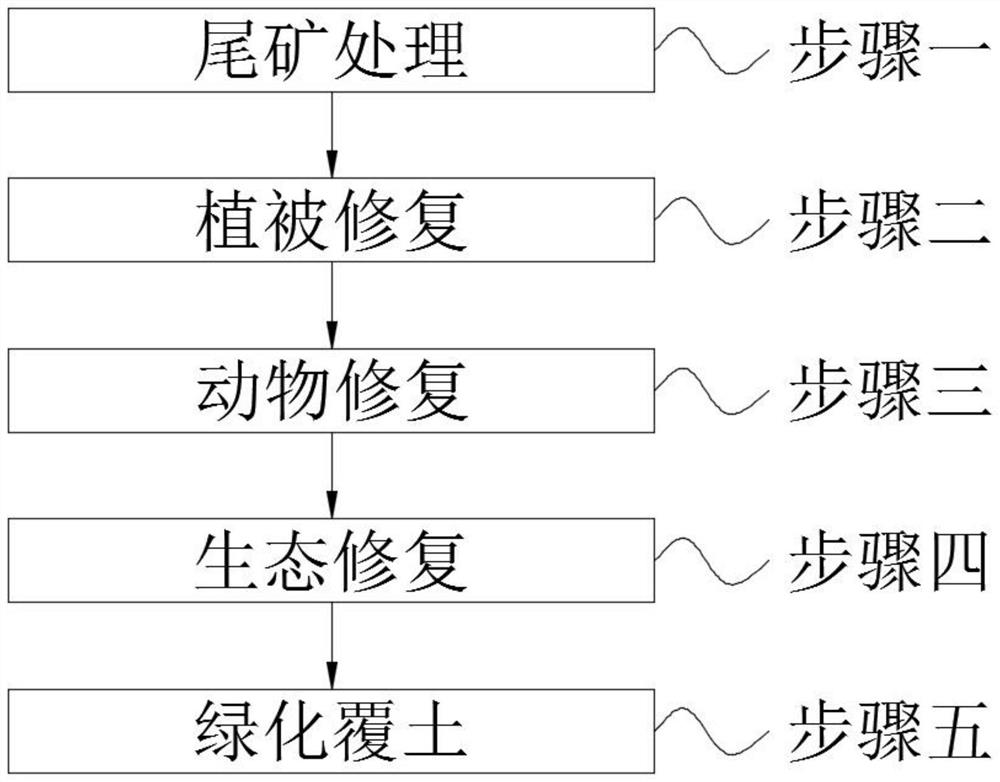

Tailing treatment and tailing pond ecological restoration method

PendingCN112703848AConducive to ecological restorationAvoid churnSoil-working methodsMicroorganismEnvironmental resource management

The invention discloses a tailing treatment and tailing pond ecological restoration method. The method comprises the steps of 1, tailing treatment; 2, vegetation restoration; 3, animal repairing; 4, ecological restoration; and 5, greening and earthing. In the step 1, mined tailings are manually cleaned, poured into a stone crusher, crushed and coarse-grained and then transported to an underground mining goaf of a mine to be used as filler for filling. According to the tailing treatment and tailing pond ecological restoration method, tailing treatment is conducted firstly, a plant planting and soil covering manner is determined according to the soil condition of a tailing pond, soil loss of the tailing pond is avoided, meanwhile, the microorganism and animal capacity of the tailing pond is increased, vegetation growth, environment protection and ecological planting are facilitated, the method is simple and rigorous in process, the method can replace other expensive tailing treatment and tailing pond ecological restoration methods, the raw materials are cheap, the cost is low, and the restoration cost is greatly saved.

Owner:甘肃建投榆中绿色矿业有限责任公司

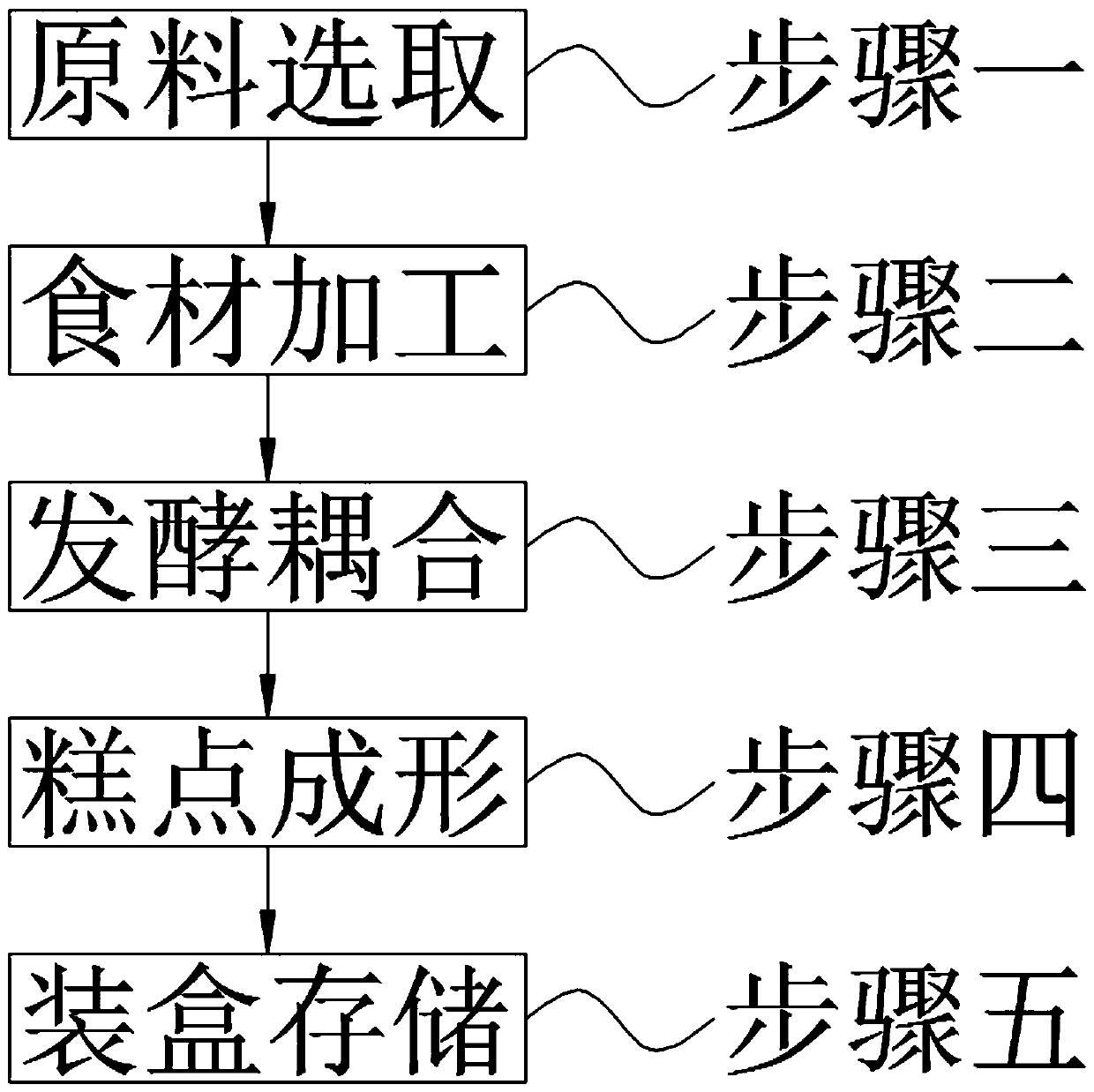

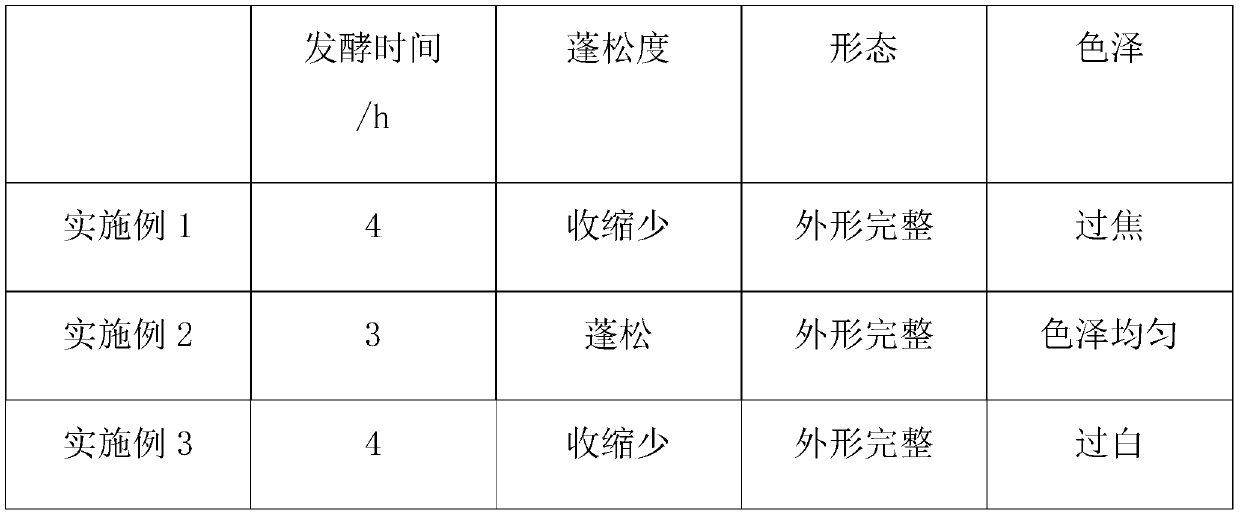

Multi-fermentation-coupled pastry and processing method thereof

PendingCN111387243AImprove tasteThe process is simple and rigorousDough treatmentPre-baking dough treatmentMouthfeelFermentation starter

The present invention discloses a multi-fermentation-coupled pastry and a processing method thereof. A formula comprises aspergillus niger, flour, sweet potatoes, taros, rhizopus, a fermentation agent, Chinese yams, eggs, white granulated sugar and fermented flour sweet sauce. The mass percentages of each component are respectively as follows: 15-25% of aspergillus niger, 10-20% of flour, 2-4% ofsweet potatoes, 10-20% of taros, 25-35% of rhizopus, 15-25% of a fermentation agent, 1-3% of Chinese yams, 5-10% of eggs, 0.5-1% of white granulated sugar and 0.5-1% of fermented flour sweet sauce. The processing method comprises the followings steps: step one, raw material selecting; step two, edible material processing; step three, fermentation coupling; step four, pastry shaping; and step five,boxing and storing. The processing method is safe and reliable and uses the aspergillus niger, rhizopus and fermentation agent as the fermentation raw materials, multi-fermentation-coupled fermentation is conducted under vacuum conditions, traditional simple fermentation-agent fermentation is abandoned, the processing method is more conducive to pastry fermentation and processing, so that the pastry is more fluffy, mouthfeel of the pastry is greatly improved, and the pastry is simple and rigorous, the raw materials are cheap and low in cost, and production cost is greatly saved.

Owner:福建省诏安四海食品有限公司

Preparation method of catalyst for converting carbon tetrachloride into chloroform

InactiveCN111790411AHigh catalytic efficiencyIncrease conversion ratePreparation by dehalogenationOrganic-compounds/hydrides/coordination-complexes catalystsOXALIC ACID DIHYDRATEPtru catalyst

The invention discloses a preparation method of a catalyst for converting carbon tetrachloride into chloroform. The formula comprises the following components: chloroplatinic acid, dichloromethane, aluminum oxide, potassium chloride, acetic acid, oxalic acid, deionized water, a manganese monomer and an adsorbent. The catalyst is prepared from the following components in percentage by mass: 15 to 25 percent of chloroplatinic acid, 20 to 35 percent of dichloromethane, 15 to 25 percent of aluminum oxide, 10 to 20 percent of potassium chloride, 2 to 4 percent of acetic acid, 10 to 20 percent of oxalic acid, 1 to 3 percent of deionized water, 6 to 11 percent of manganese monomer and 0.5 to 1 percent of the adsorbent. The method is safe and reliable, aluminum oxide and chloroplatinic acid are used as carriers to prepare the catalyst for converting carbon tetrachloride into chloroform. A traditional catalytic hydrogenation reaction mode is abandoned; clipping and dipping of the adsorbent aremore beneficial to carrier processing, dichloromethane is added as a diluent, the catalytic efficiency of the carbon tetrachloride-to-chloroform catalyst is further improved, carbon tetrachloride-to-chloroform catalysis is facilitated, the catalyst is high in activity and conversion rate, the process is simple and rigorous, the raw materials are cheap and low in cost, and the production cost is greatly reduced.

Owner:JIANGSU LEE & MAN CHEM

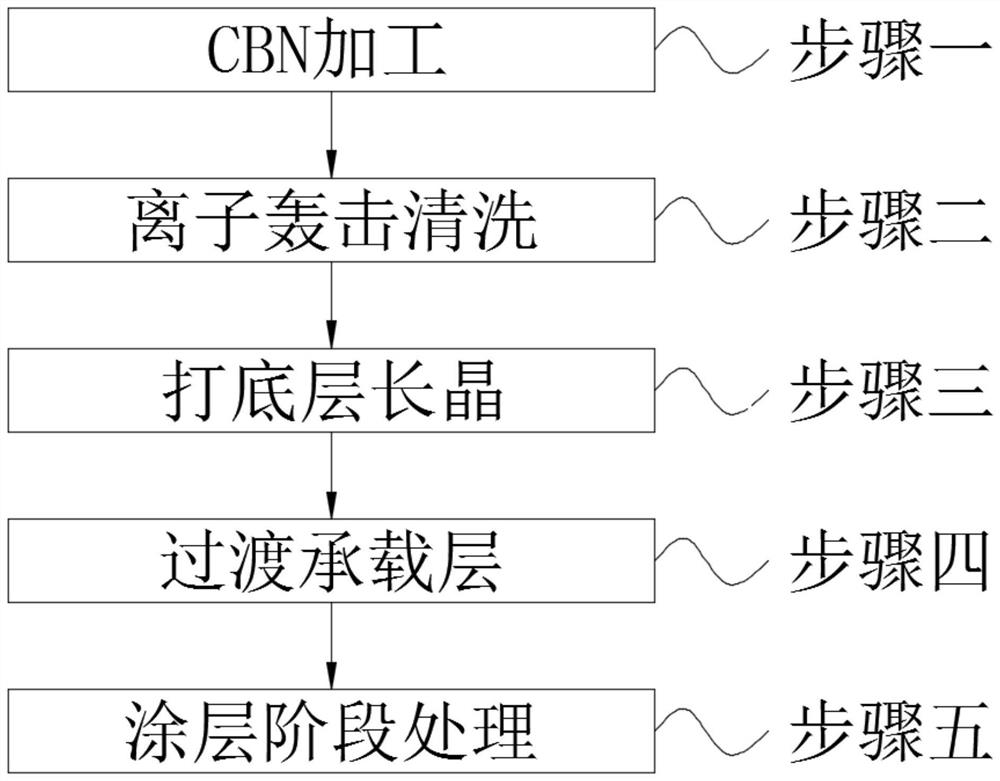

Method for coating CBN cutter material

InactiveCN112575290AHigh hardnessEasy to operateVacuum evaporation coatingSputtering coatingIon bombardmentThin membrane

The invention discloses a method for coating a CBN cutter material. The method comprises the following steps of step 1, CBN processing; step 2, ion bombardment cleaning; step 3, priming coat crystal growth; step 4, bearing layer transition; and step 5, coating stage treatment, wherein in the step 1, the property and style of the CBN cutter material are manually detected, a target material raw material is selected to be coated on a proper CBN cutter material, and the target material raw material is put into a plasma gun. The method for coating the CBN cutter material is easy to operate and lowin cost, a cylindrical arc technology is adopted, the high-hardness coating is applied to a CBN blade, hardware understanding and technological parameter design are combined, the adhesiveness can be improved on the CBN material, the adhesion strength can be comparable with that of steel, the film hardness is extremely high, and the advantages of good wear resistance and high temperature resistanceare achieved, so that the method is suitable for super-hard dry type cutting process, the process is simple and rigorous, the raw materials are cheap, the cost is low, and the production cost is greatly saved.

Owner:东莞市普拉提纳米科技有限公司

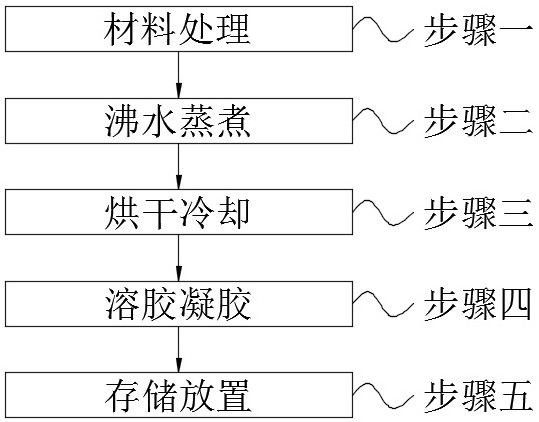

Preparation method of anti-wrinkle cotton and linen composite fiber material for garment production

PendingCN112878043AHigh densityImprove wrinkle resistanceWrinkle resistant fibresGrip property fibresFiberCeramic materials

The invention discloses a preparation method of an anti-wrinkle cotton and linen composite fiber material for garment production. The preparation method comprises the following steps of step 1, material treatment; step 2, cooking with boiling water; step 3, drying and cooling; step 4, sol-gel preparation; and step 5, storing and placing, wherein in the first step, proper cotton and linen raw materials are manually selected according to finished products needing to be processed, and the cotton and linen raw materials are screened and dedusted. The preparation method of the anti-wrinkle cotton and linen composite fiber material for garment production is easy to operate and low in cost, processing is conducted in the mode that soaking is conducted firstly and then sol-gel is conducted, and the density of the cotton and linen composite fiber material is increased; and meanwhile, the cotton and linen composite fiber material is softer, the anti-wrinkle performance of the cotton and linen composite fiber material is improved, use by a user is facilitated, the process is simple and rigorous, the production technology can replace other relatively expensive cotton and linen composite fiber material production technologies, the effect is remarkable, raw materials are cheap and low in cost, processing is convenient, the production cost is greatly saved, and processing and production are facilitated.

Owner:XINXIANG PATRON SAINT SPECIAL FABRIC

Preparation method of chitosan-based uvioresistant finishing agent

InactiveCN112281474AEasy to useEasy to produceBiochemical fibre treatmentLight resistant fibresSodium lactateTitanium oxide

The invention discloses a preparation method of a chitosan-based uvioresistant finishing agent. A formula of the chitosan-based uvioresistant finishing agent is prepared from the following componentsin percentage by mass: 15-25% of ammonium polyphosphate, 20-30% of chitosan, 15-25% of sodium lactate, 10-20% of 2,4-dihydroxy benzophenone, 2-4% of 4-nitro-1, 10-20% of titanium dioxide, 1-3% of sodium hydroxide, 5-10% of methylbenzene, 0.5-1% of citric acid, 0.5-1% of ethyl alcohol and 1-3% of a dispersing agent. According to the preparation method, safety and reliability are achieved, the chitosan-based uvioresistant finishing agent is commonly prepared by adopting the chitosan as a processing raw material and adding ammonium polyphosphate, sodium lactate, 2,4-dihydroxy benzophenone, 4-nitro-1, titanium dioxide, sodium hydroxide and methylbenzene, the ultraviolet resistance is enhanced, meanwhile, the antibacterial property is achieved, user use is facilitated, making is simple and convenient, time and labor are saved, and user production is facilitated.

Owner:YINGKOU INST OF TECH

Film with low interference degree on sensitivity of capacitive screen and processing technology

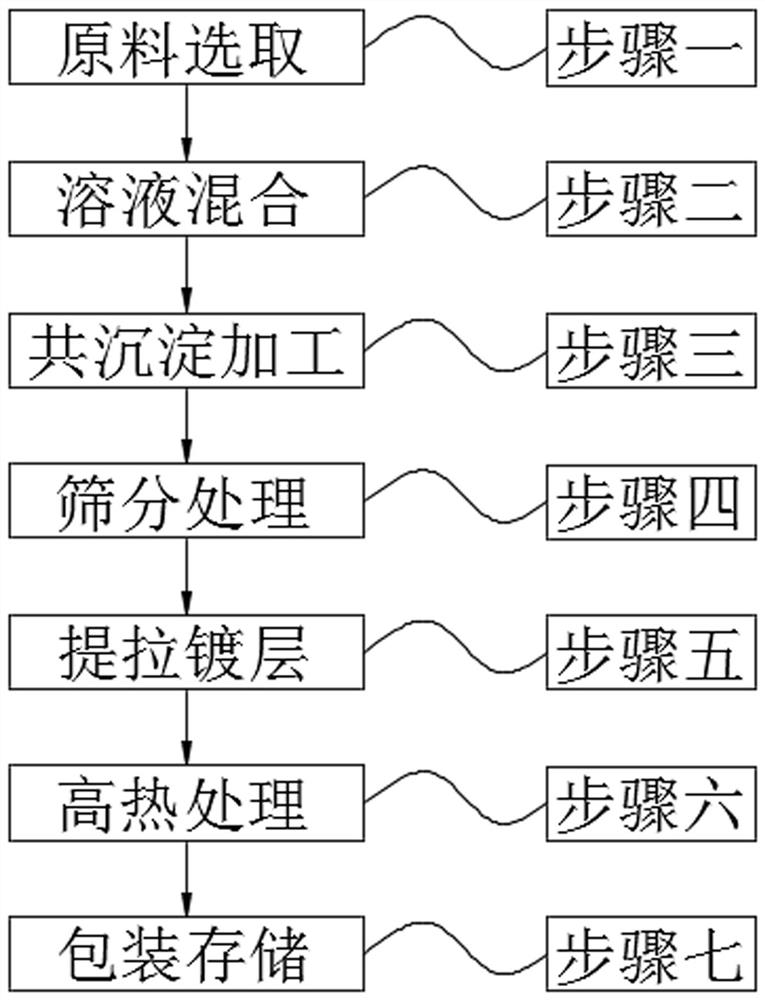

The invention discloses a film with low interference degree on the sensitivity of a capacitive screen and a processing technology. The formula comprises the following components: a quartz glass substrate, metal indium, ammonium carbonate, tin sulfate, nitric acid, tin chloride, alcohol, ammonia water, a catalyst and an additive, the mass percentage of each component is as follows: 15-25% of a quartz glass substrate, 20-30% of metal indium, 15-25% of ammonium carbonate, 10-20% of tin sulfate, 2-4% of nitric acid, 10-20% of tin chloride, 1-3% of alcohol, 5-10% of ammonia water, 0.5-1% of a catalyst and 0.5-1% of an additive; the preparation process comprises the following steps: step 1, selecting raw materials; step 2, solution mixing; step 3, coprecipitation processing; step 4, processing and screening; step 6, lifting the plating layer; step 6, high heat treatment; and step 7, packaging and storing. According to the invention, the ITO sol is prepared by adopting coprecipitation processing and ultrasonic reaction so that the quartz glass substrate and the ITO sol are fused more tightly, the conductivity of the capacitive screen film is improved, and the sensitivity of the capacitivescreen film is improved.

Owner:QINGYUAN LANHAI HUIGU INTELLIGENT TECH CO LTD

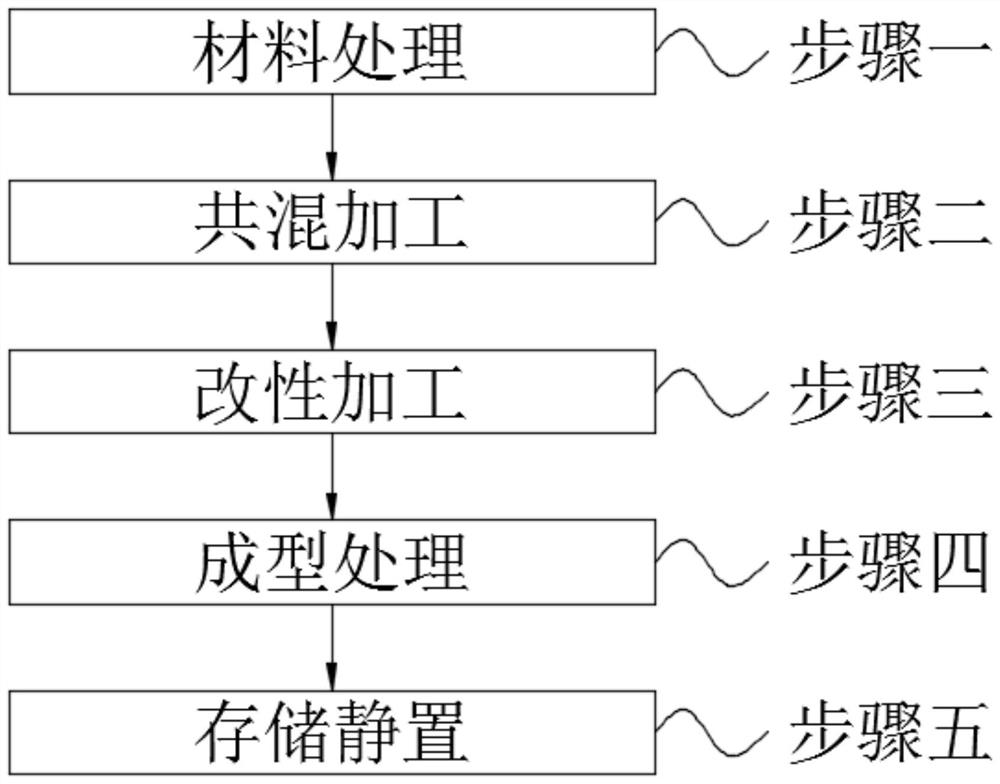

Polylactic acid resin, PBAT and talcum powder modification processing technology

The invention discloses a polylactic acid resin, PBAT and talcum powder modification processing technology. The technology comprises the following steps: 1, performing material treatment; 2, performing blending processing; 3, performing modification processing; 4, performing forming treatment; 5, performing storing and standing, wherein in the step 1, proper polylactic acid resin, PBAT and talcum powder are manually selected, and the polylactic acid resin, PBAT and talcum powder are respectively filtered; the polylactic resin, PBAT and talcum powder modification processing technology is easy to operate and low in cost, the polylactic resin, PBAT and talcum powder are adopted for modification treatment, then injection molding is conducted, the operation is easy, resources are saved, time and labor are saved, and the polylactic resin, PBAT and talcum powder modification processing technology has excellent strength and elasticity and is beneficial for users to use; the process is simple and rigorous, can replace other expensive polylactic resin, PBAT and talcum powder modification technologies, has the advantages of remarkable effect, cheap materials and low cost, greatly saves the cost, and is beneficial to processing and production.

Owner:大连盈诺环保科技有限公司

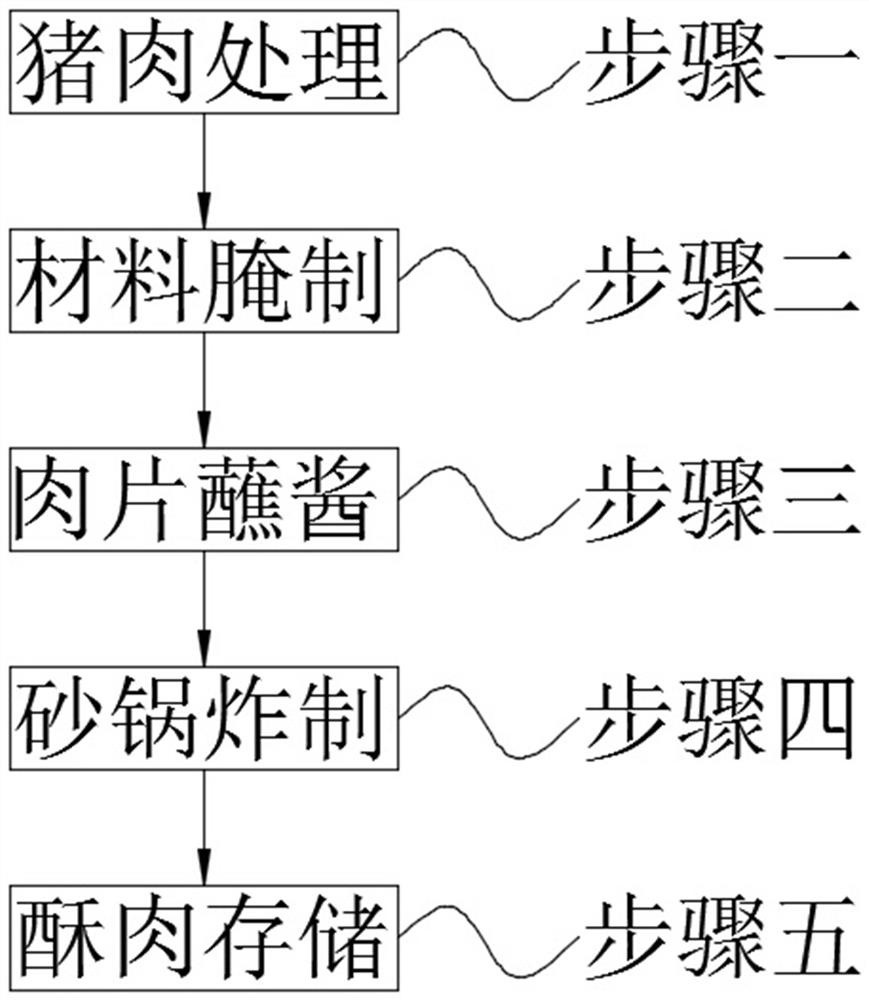

Preparation method of small crispy pork slices suitable for children's mouth feel

PendingCN114052205AAvoid out of shapeGreat tasteFood ingredient as mouthfeel improving agentBiotechnologyNutritive values

The invention discloses a preparation method of small crispy pork slices suitable for children's mouth feel, and the preparation method comprises the following steps of: 1, pork treatment; 2, material pickling; 3, dipping of sliced meat in sauce; 4, frying in a marmite; and 5, storage of the crispy pork slices; wherein in the step 1, pig tenderloin which is bright in color, ruddy in color, transparent in meat quality, compact in texture, rich in elasticity, capable of being quickly restored after being pressed by hands and special in pork flavor is manually selected; the small crispy pork slices are safe and reliable, the pork tenderloin is adopted as the raw material, sweet potato starch and eggs are added, the mouthfeel is good and the nutritional value is high, the phenomenon that the small crispy pork slices is not shaped during frying is avoided, and the pork slices are fried with rapeseed oil over big fire and then over soft fire, so that the small crispy pork slices are not loose, better in taste and suitable for children to eat; the technology can replace other expensive small crispy pork slice processing technologies, raw materials are cheap and low in cost, the production cost is greatly saved, and small crispy pork slice processing production is facilitated.

Owner:ZHANGZHOU SHENGLONG FOOD

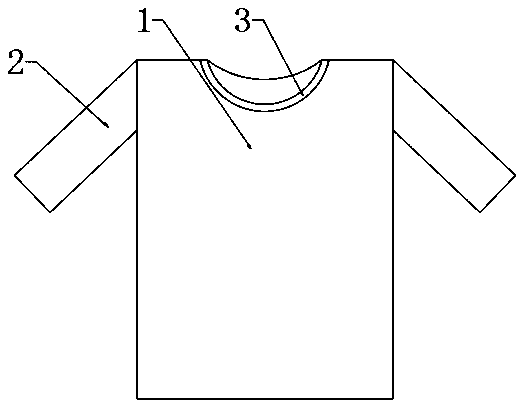

Non-ironing environment-friendly breathable sunscreen summer clothes and manufacturing method

PendingCN111466623AGood for healthConvenient for daily useWoven fabricsProtective garmentSpinningEngineering

The invention discloses non-ironing environment-friendly breathable sunscreen summer clothes and a manufacturing method. The non-ironing environment-friendly breathable sunscreen summer clothes comprise clothes cut pieces, clothes cuffs and a clothes neckline. The formula comprises silk, flax, polyamide fibers, polyester fibers, milk protein fibers, calcium carbonate, acetone, a dehydrating agent,a catalyst and a coloring agent. According to the non-ironing environment-friendly breathable sunscreen summer clothes and the manufacturing method thereof, silk, flax, polyamide fibers, polyester fibers and milk protein fibers are adopted, the odor is small, and energy conservation and environmental protection are facilitated; meanwhile, silk, flax, polyamide fibers, polyester fibers and milk protein fibers are moderate in the aspects of dyeing and finishing, temperature, alkalinity and the like, thereby facilitating health of the user; in addition, the summer clothes are formed by adoptinga screw extruder for spinning and then using a loom for interweaving, so that the crease resistance, the breathability and the sun protection of the summer clothes are improved, the density is greatlyincreased, the color fastness during dyeing is improved, and the summer clothes are neat, attractive, convenient to clean, low in cost and beneficial to daily use of users.

Owner:湖南亚西欧服饰有限公司

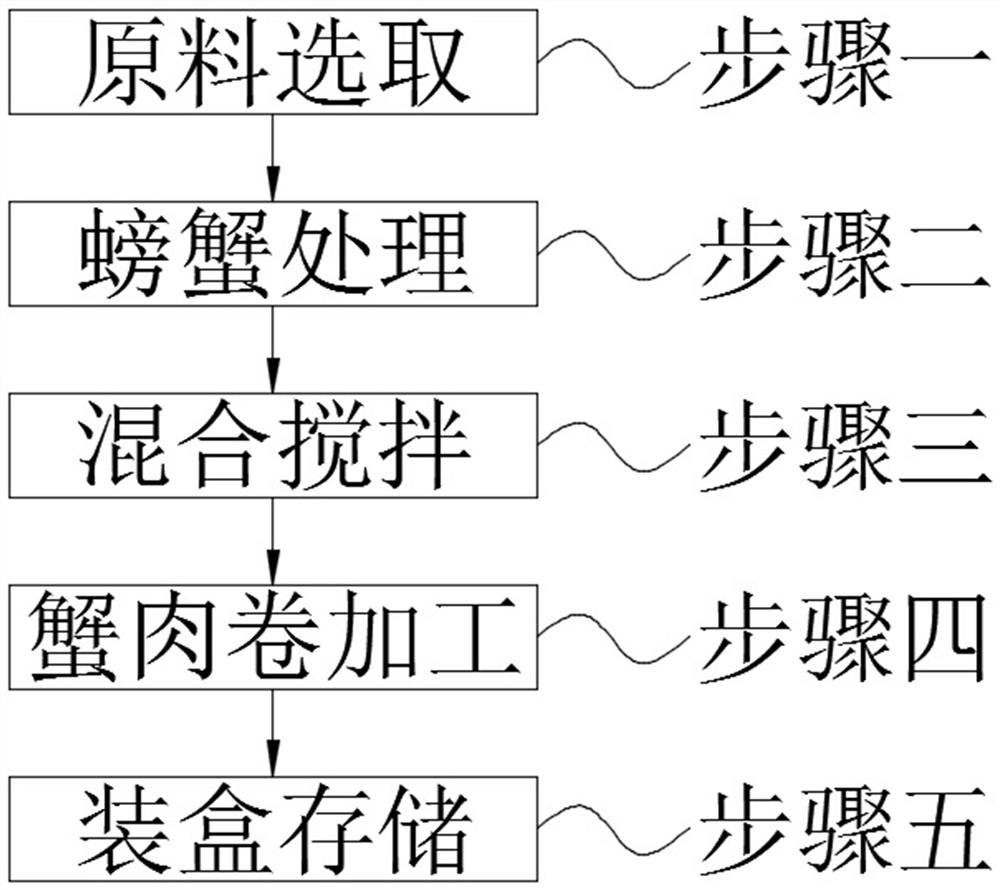

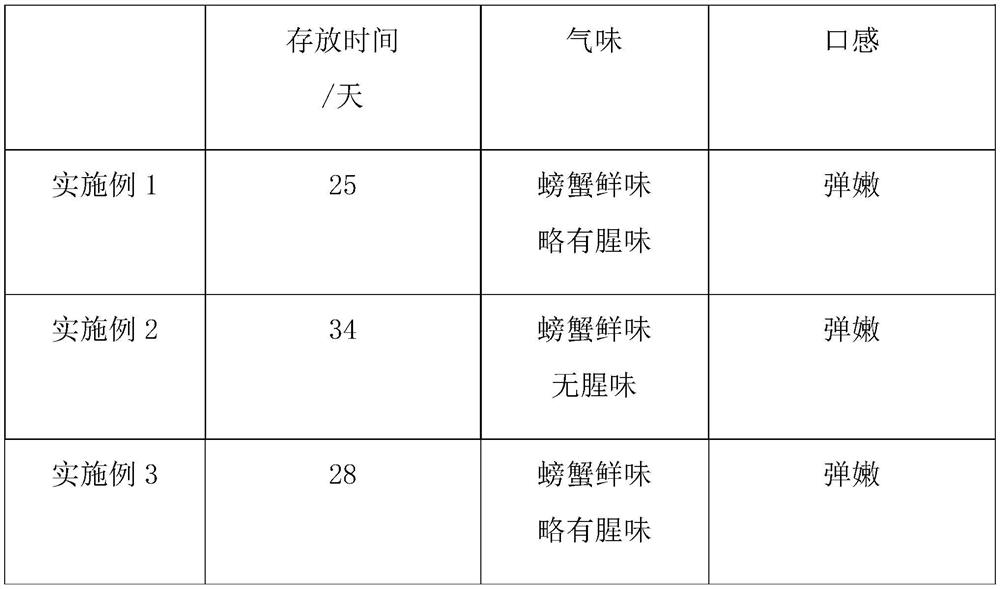

Crab meat rolls and preparation method thereof

PendingCN111838584AKeep it authenticGreat tasteFood ingredient as mouthfeel improving agentBiotechnologyNutritive values

The invention discloses crab meat rolls and a preparation method thereof. The crab meat roll comprises the following components: by mass, 15-25 parts of flour, 25-35 parts of crabs, 15-25 parts of pork stuffing, 10-20 parts of starch, 2-4 parts of egg white, 10-20 parts of white radishes, 1-3 parts of cooking wine, 5-10 parts of edible salt, 1-3 parts of yellow peppers and 1-3 parts of black sesame seeds. The crab meat rolls are safe and reliable, crab meat is used as a raw material and is added with the pork stuffing and the white radishes and is mixed, and the fresh crab meat roll maintainsthe original taste and flavor of crab meat, increases the freshness, is fresh, tender and refreshing, has high nutritional value, is mixed with yellow pepper and black sesame, has good color and luster, is fresh, improves the mouthfeel, has good taste, is simple and rigorous in process, can replace other expensive crab meat roll processing technologies, greatly saves the production cost, and is beneficial to the production of the crab meat roll.

Owner:东山远隆食品有限公司

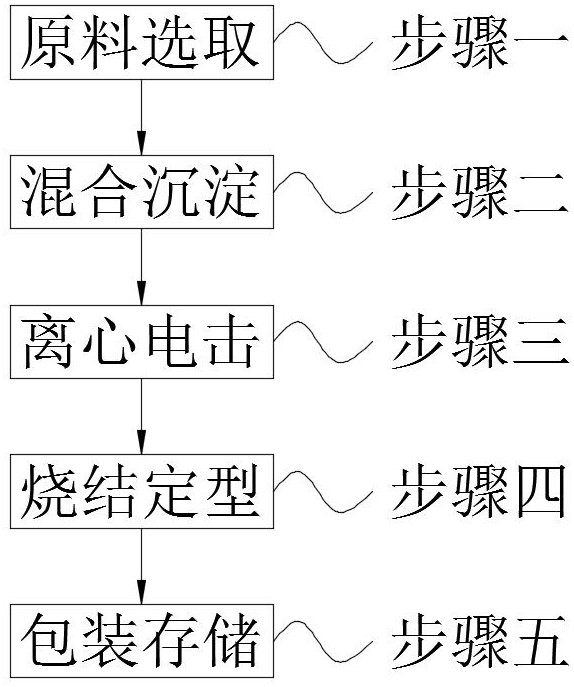

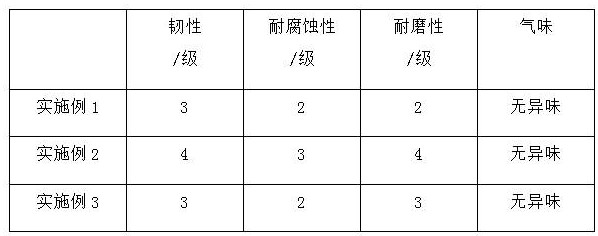

Composite material applied to electronic equipment and production method thereof

The invention discloses a composite material applied to electronic equipment and a production method of the composite material, and the formula of the composite material comprises the following components in percentage by mass: 15-25% of epoxy resin, 20-30% of graphite, 15-25% of silicon carbide, 10-20% of aluminum oxide, 2-4% of potassium permanganate, 10-20% of deionized water, 1-3% of an ethylene-acrylic acid copolymer, 5-10% of styrene, 0.5-1% of hydrogen peroxide, 0.5-1% of an initiator and 1-3% of a diluent, the composite material is safe and reliable, graphite, silicon carbide, aluminumoxide, an ethylene-acrylic acid copolymer and styrene are adopted as raw materials, centrifugal electric shock is conducted to prepare a composite material raw material, then epoxy resin is smeared,sintering is conducted, the toughness, abrasion resistance and corrosion resistance of the composite material of the electronic equipment are improved, the performance is more stable, and the machining process is free of pollution, and environmental protection is facilitated.

Owner:惠州市国鹏科技有限公司

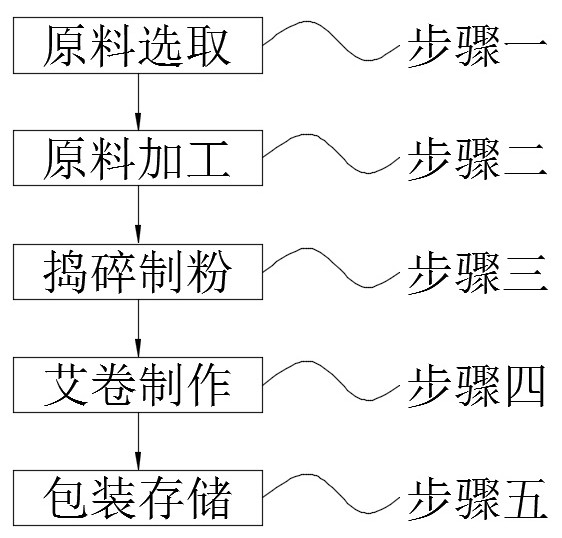

Moxibustion stick and manufacturing method thereof

PendingCN111904851AEasy to useFierce firepowerDevices for heating/cooling reflex pointsPharmaceutical product form changeRadix AconitiMugwort

The invention discloses a moxibustion stick and a manufacturing method thereof.The moxibustion stick is prepared from the components in parts by mass: 15-25 parts of Chinese mugwort moxa, 20-30 partsof mulberry bark paper, 15-25 parts of flos carthami, 10-20 parts of rhizoma chuanxiong, 10-20 parts of radix aconiti carmichaeli and 10-20 parts of radix angelicae pubescentis. The manufacturing method of the moxibustion stick comprises the following steps: step 1, selecting raw materials; 2, processing the raw materials; 3, carrying out mashing and powdering; 4, preparing moxa rolls; and step 5,performing packaging and storing. The moxibustion stick is safe and reliable, is prepared from Chinese mugwort moxa as a raw material, is matched with traditional Chinese medicines flos carthami, rhizoma chuanxiong, radix aconiti carmichaeli and radix angelicae pubescentis, is prepared by rolling mulberry bark paper, has the effects of strong fire, strong thermal radiation penetrating power, lasting combustion and the like, can be suitable for conventional moxibustion methods and special moxibustion methods such as acupuncture and moxibustion, is wide in application range, and is beneficial for users to use. The raw materials are cheap, the cost is low, and the production cost is saved.

Owner:湖南源一本草生物科技有限责任公司

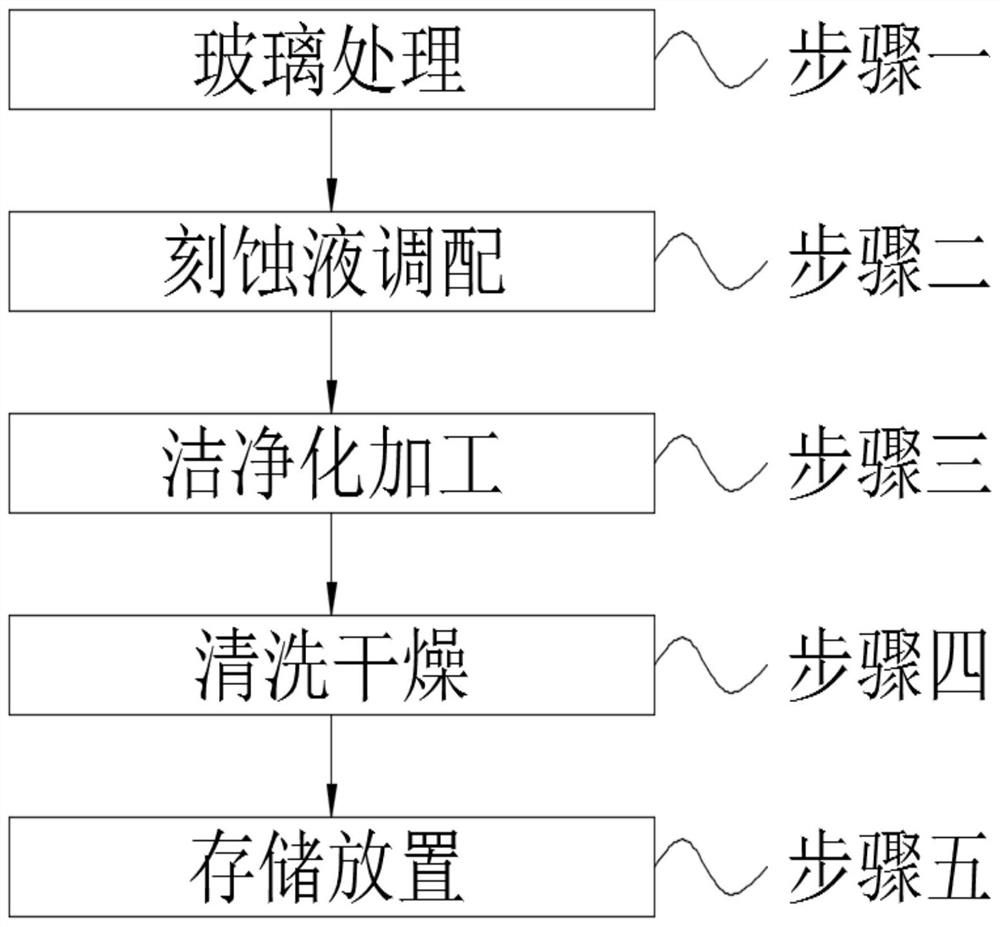

Cleaning processing technology of anti-glare glass

PendingCN112499985AIncreased anti-glareEasy to useCoatingsManufacturing technologyProcess engineering

The invention discloses a cleaning processing technology of anti-glare glass. The cleaning processing technology comprises the following steps: step 1, glass treating; step 2, preparing an etching solution; step 3, cleaning and processing; step 4, cleaning and drying; step 5, storing and placing; wherein in the step 1, glass raw materials with proper sizes are manually selected according to the anti-glare glass to be processed, and the glass raw materials are scrubbed; the anti-glare glass cleaning processing technology has the advantages of simple operation, low cost, simple operation, resource saving, operator reduction, time saving, labor saving, cleaning processing under aseptic conditions, facilitation of the increase of the anti-glare degree of the glass, facilitation of the use of users, and improvement of the anti-glare degree of the anti-glare glass. And the process is simple and rigorous, can replace other expensive anti-glare glass processing and manufacturing technologies,has the advantages of obvious effect, cheap materials and low cost, greatly saves the cost, and is beneficial to processing and production.

Owner:郴州市天诚光电科技有限公司

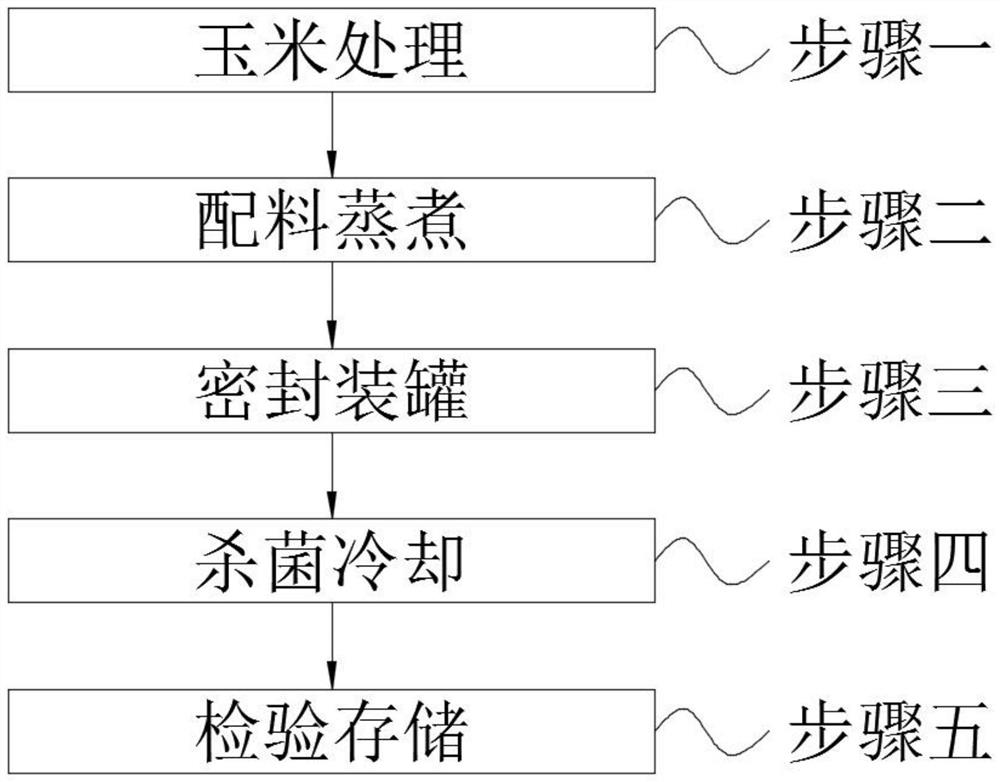

Preparation process of canned multi-flavor tomato juice corn kernels

The invention discloses a preparation process of canned multi-flavor tomato juice corn kernels. The preparation process comprises the following steps of: step 1, treating corns; step 2, cooking ingredients; step 3, sealing and canning; step 4, sterilizing and cooling; and step 5, inspecting and storing, wherein in the step 1, fresh, full, mature and non-rotten corns are manually selected, and the corns are cleaned to remove outer leaves and filaments. The preparation process of the canned multi-flavor tomato juice corn kernels is simple to operate and low in cost; the materials are selected firstly, and then the ingredients are cooked, sealed and sterilized to prepare the canned multi-flavor tomato juice corn kernels; the cooking temperature can be adjusted according to different corns, so that the sweetness of the corns is improved; meanwhile, tomato juice is added, so that the taste of the canned multi-flavor tomato juice corn kernels is improved, and the canned multi-flavor tomato juice corn kernels are convenient for users to eat; and the process is simple and rigorous, the raw materials are cheap and low in cost, the processing is convenient, the production cost is greatly saved, and the processing and production are facilitated.

Owner:FUJIAN BISHAN FOOD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com