Preparation method of catalyst for converting carbon tetrachloride into chloroform

A technology of carbon tetrachloride and catalyst, which is applied in the field of preparation of carbon tetrachloride to chloroform catalyst, and can solve problems such as short life, unfavorable carbon tetrachloride to chloroform catalysis, troublesome processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A carbon tetrachloride to chloroform catalyst, the formula includes: chloroplatinic acid, methylene chloride, aluminum oxide, potassium chloride, acetic acid, oxalic acid, deionized water, manganese monomer and adsorbent, the mass percentage of each component The contents are: 16% chloroplatinic acid, 20% dichloromethane, 25% aluminum oxide, 10% potassium chloride, 4% acetic acid, 10% oxalic acid, 3% deionized water, 11% dichloromethane and adsorbent 1 %.

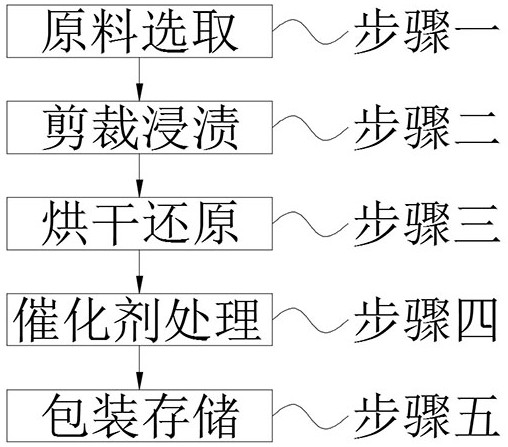

[0033] A preparation method of a carbon tetrachloride-to-chloroform catalyst, comprising the following steps: Step 1, raw material selection; Step 2, cutting and impregnating; Step 3, drying and reducing; Step 4, catalyst treatment; Step 5, packaging and storing;

[0034] Wherein in the above-mentioned step 1, according to the mass percentage content of each component, it is respectively: 16% of chloroplatinic acid, 20% of methylene chloride, 25% of aluminum oxide, 10% of potassium chloride, 4% of acetic acid, 10% of...

Embodiment 2

[0049] A kind of carbon tetrachloride turns chloroform catalyst, formula comprises: Chloroplatinic acid, dichloromethane, aluminum oxide, potassium chloride, acetic acid, oxalic acid, deionized water, manganese monomer and adsorbent, the mass percent of each component The contents are: 16% chloroplatinic acid, 25% dichloromethane, 20% aluminum oxide, 10% potassium chloride, 4% acetic acid, 10% oxalic acid, 3% deionized water, 11% dichloromethane and adsorbent 1 %.

[0050]A preparation method of a carbon tetrachloride-to-chloroform catalyst, comprising the following steps: Step 1, raw material selection; Step 2, cutting and impregnating; Step 3, drying and reducing; Step 4, catalyst treatment; Step 5, packaging and storing;

[0051] Wherein in the above-mentioned step 1, according to the mass percentage content of each component, it is respectively: 16% of chloroplatinic acid, 25% of methylene chloride, 20% of aluminum oxide, 10% of potassium chloride, 4% of acetic acid, 10% o...

Embodiment 3

[0067] A carbon tetrachloride to chloroform catalyst, the formula includes: chloroplatinic acid, methylene chloride, aluminum oxide, potassium chloride, acetic acid, oxalic acid, deionized water, manganese monomer and adsorbent, the mass percentage of each component The contents are: 16% chloroplatinic acid, 30% dichloromethane, 15% aluminum oxide, 10% potassium chloride, 4% acetic acid, 10% oxalic acid, 3% deionized water, 11% dichloromethane and adsorbent 1 %.

[0068] A preparation method of a carbon tetrachloride-to-chloroform catalyst, comprising the following steps: Step 1, raw material selection; Step 2, cutting and impregnating; Step 3, drying and reducing; Step 4, catalyst treatment; Step 5, packaging and storing;

[0069] Wherein in the above-mentioned step 1, according to the mass percentage content of each component is respectively: 16% of chloroplatinic acid, 30% of methylene chloride, 15% of aluminum oxide, 10% of potassium chloride, 4% of acetic acid, 10% of oxa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com