Multi-fermentation-coupled pastry and processing method thereof

A processing method and pastry technology, which is applied in the field of multi-fermentation coupling pastry and processing, can solve the problems of unfavorable pastry fermentation processing, expensive processing materials, increased production costs, etc., and achieve the effects of convenient processing, low cost and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

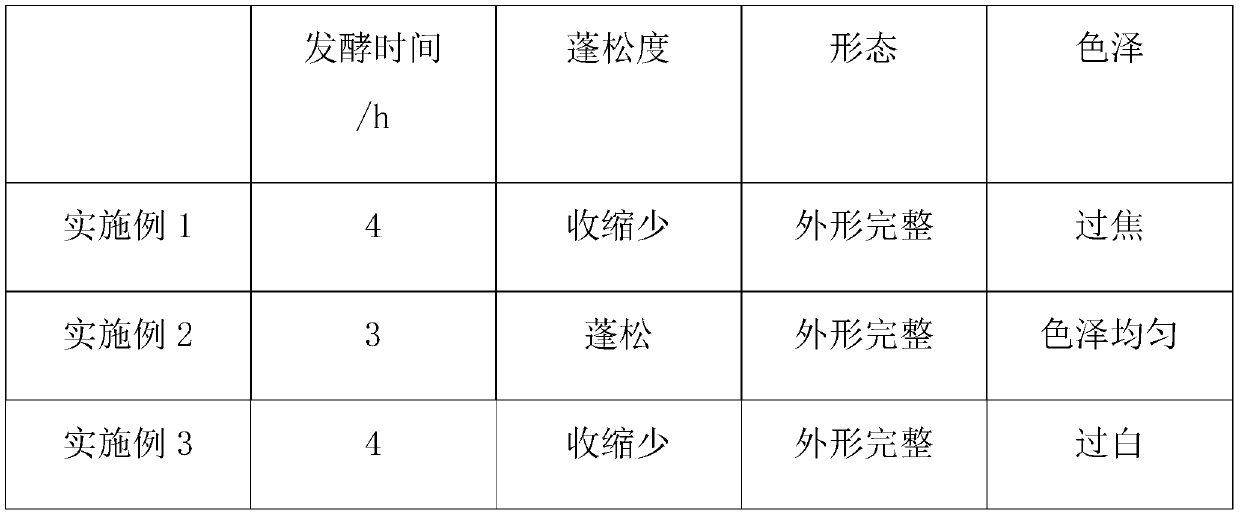

Embodiment 1

[0032] A multi-fermentation coupling pastry, the formula includes: aspergillus niger, flour, sweet potato, taro, rhizopus, starter, yam, eggs, white sugar and sweet noodle sauce, and the mass percentages of each component are: aspergillus niger 16%, 10% flour, 4% sweet potato, 10% taro, 20% rhizopus, 25% starter, 3% yam, 10% egg, 1% white sugar and 1% sweet bean paste.

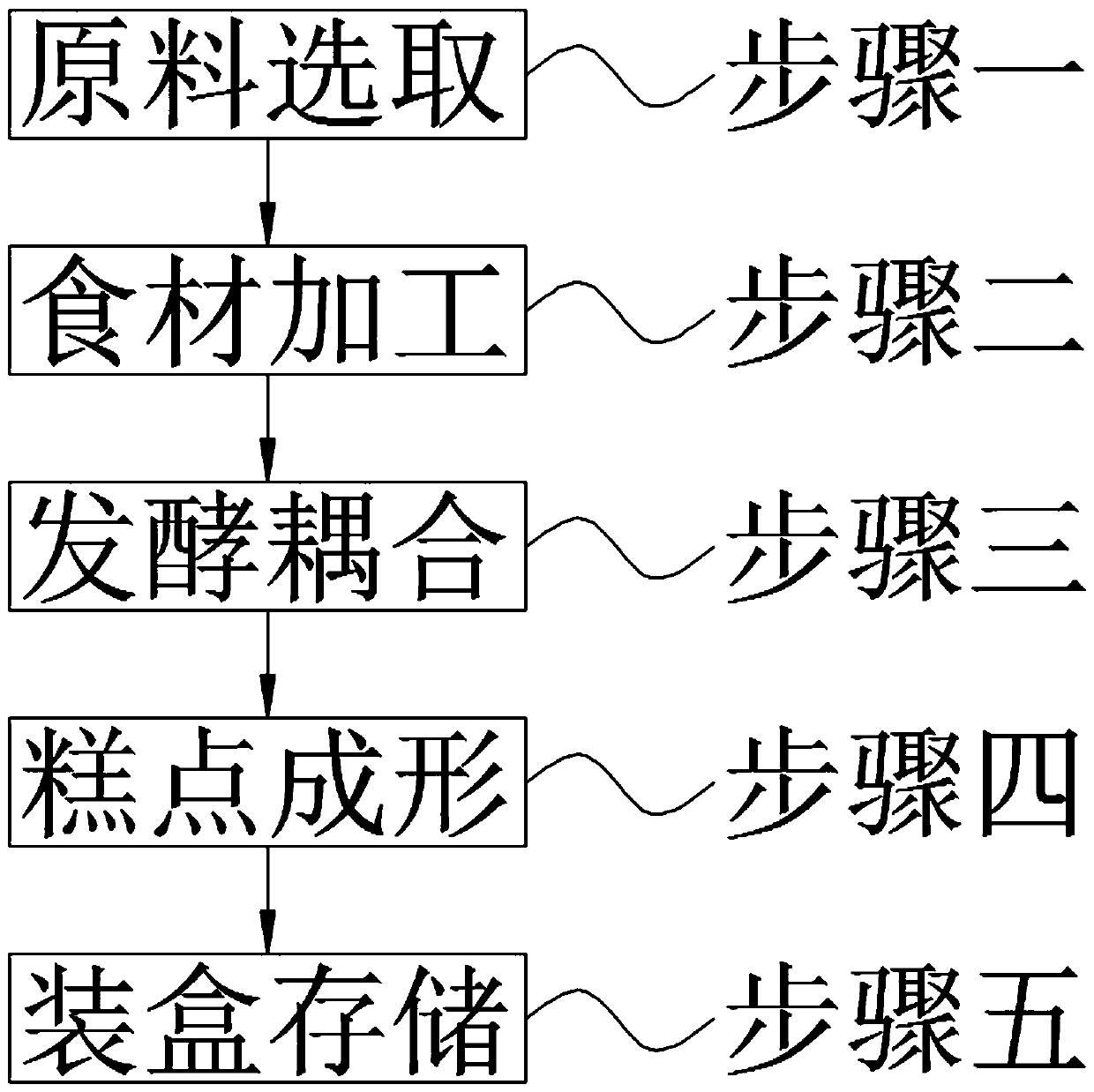

[0033] A processing method for multi-fermentation coupling pastry, comprising the following steps: step 1, raw material selection; step 2, food material processing; step 3, fermentation coupling; step 4, pastry forming; step 5, boxing and storage;

[0034] Wherein above-mentioned step 1, according to the mass percent content of each component is respectively: aspergillus niger 16%, flour 10%, sweet potato 4%, taro 10%, rhizopus 20%, starter 25%, yam 3%, egg 10%, white granulated sugar 1% and sweet noodle sauce 1% are selected, and weighed according to the sum of the weight percentages being 1;

[0035] In the...

Embodiment 2

[0050] A multi-fermentation coupling pastry, the formula includes: aspergillus niger, flour, sweet potato, taro, rhizopus, starter, yam, eggs, white sugar and sweet noodle sauce, and the mass percentages of each component are: aspergillus niger 16%, 10% flour, 4% sweet potato, 10% taro, 25% rhizopus, 20% starter, 3% yam, 10% egg, 1% white sugar and 1% sweet bean paste.

[0051] A processing method for multi-fermentation coupling pastry, comprising the following steps: step 1, raw material selection; step 2, food material processing; step 3, fermentation coupling; step 4, pastry forming; step 5, boxing and storage;

[0052] Wherein above-mentioned step 1, according to the mass percentage content of each component is respectively: aspergillus niger 16%, flour 10%, sweet potato 4%, taro 10%, rhizopus 25%, starter 20%, yam 3%, egg 10%, white granulated sugar 1% and sweet noodle sauce 1% are selected, and weighed according to the sum of the weight percentages being 1;

[0053] In ...

Embodiment 3

[0068] A multi-fermentation coupling pastry, the formula includes: aspergillus niger, flour, sweet potato, taro, rhizopus, starter, yam, eggs, white sugar and sweet noodle sauce, and the mass percentages of each component are: aspergillus niger 16%, 10% flour, 4% sweet potato, 10% taro, 30% rhizopus, 15% starter, 3% yam, 10% egg, 1% white sugar and 1% sweet bean sauce.

[0069] A processing method for multi-fermentation coupling pastry, comprising the following steps: step 1, raw material selection; step 2, food material processing; step 3, fermentation coupling; step 4, pastry forming; step 5, boxing and storage;

[0070] Wherein above-mentioned step 1, according to the mass percentage content of each component is respectively: aspergillus niger 16%, flour 10%, sweet potato 4%, taro 10%, rhizopus 25%, starter 20%, yam 3%, egg 10%, white granulated sugar 1% and sweet noodle sauce 1% are selected, and weighed according to the sum of the weight percentages being 1;

[0071] In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com