Film with low interference degree on sensitivity of capacitive screen and processing technology

A processing technology and technology of capacitive screen, applied in the field of capacitive screen, can solve the problems of low touch sensitivity, poor electrical conductivity, reduced sensitivity, etc., and achieve the effects of improving production efficiency, low cost, and improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A film with low interference to the sensitivity of the capacitive screen, the formula includes: quartz glass substrate, metal indium, ammonium carbonate, tin sulfate, nitric acid, tin chloride, alcohol, ammonia water, catalyst, additives, the mass percentage of each component The contents are: 16% quartz glass substrate, 20% metal indium, 25% ammonium carbonate, 10% tin sulfate, 4% nitric acid, 10% tin chloride, 3% alcohol, 10% Ammonia, 1% catalyst and 1% additive.

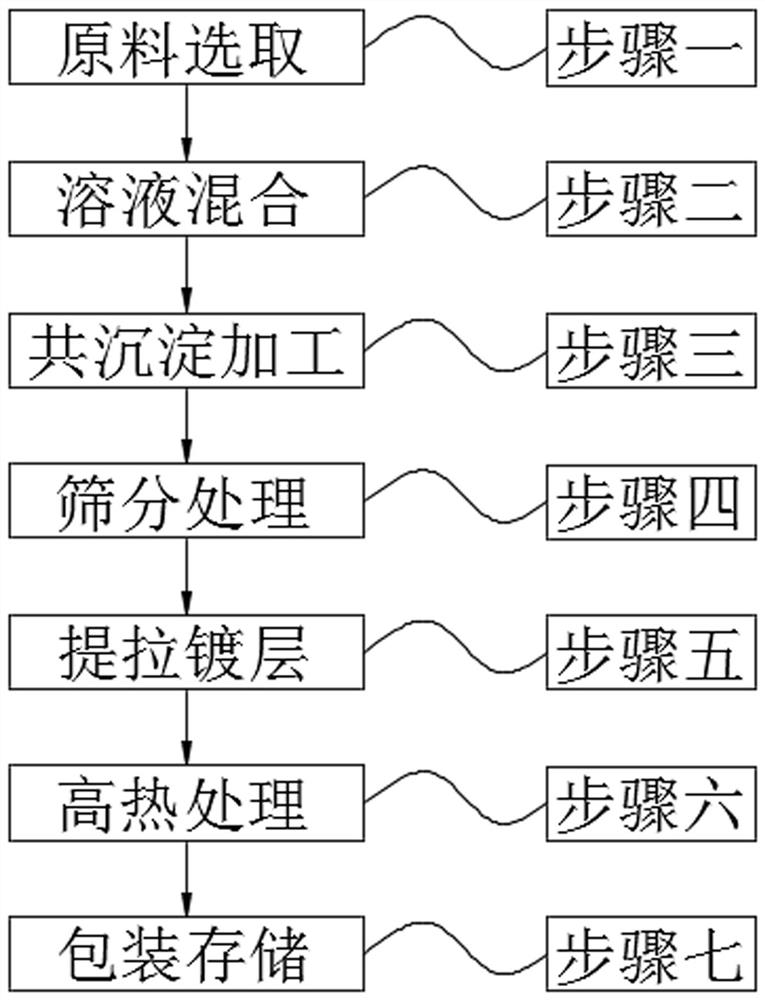

[0032] A processing technology for pasting films with low sensitivity to capacitive screens, comprising the following steps: Step 1, raw material selection; Step 2, solution mixing; Step 3, co-precipitation processing; Step 4, treatment and screening; Step 5, pulling Coating; step six, high heat treatment; step seven, packaging and storage;

[0033] Wherein in above-mentioned step 1, according to the mass percentage content of each component is respectively: 16% quartz glass substrate, 20% metal indium, 25...

Embodiment 2

[0049]A film with low interference to the sensitivity of the capacitive screen, the formula includes: quartz glass substrate, metal indium, ammonium carbonate, tin sulfate, nitric acid, tin chloride, alcohol, ammonia water, catalyst, additives, the mass percentage of each component The contents are: 16% quartz glass substrate, 25% metal indium, 20% ammonium carbonate, 10% tin sulfate, 4% nitric acid, 10% tin chloride, 3% alcohol, 10% Ammonia, 1% catalyst and 1% additive.

[0050] A processing technology for pasting films with low sensitivity to capacitive screens, comprising the following steps: Step 1, raw material selection; Step 2, solution mixing; Step 3, co-precipitation processing; Step 4, treatment and screening; Step 5, pulling Coating; step six, high heat treatment; step seven, packaging and storage;

[0051] Wherein in above-mentioned step 1, according to the mass percentage content of each component is respectively: 16% quartz glass substrate, 25% metallic indium, ...

Embodiment 3

[0067] A film with low interference to the sensitivity of the capacitive screen, the formula includes: quartz glass substrate, metal indium, ammonium carbonate, tin sulfate, nitric acid, tin chloride, alcohol, ammonia water, catalyst, additives, the mass percentage of each component The contents are: 16% quartz glass substrate, 30% metal indium, 15% ammonium carbonate, 10% tin sulfate, 4% nitric acid, 10% tin chloride, 3% alcohol, 10% Ammonia, 1% catalyst and 1% additive.

[0068] A processing technology for pasting films with low sensitivity to capacitive screens, comprising the following steps: Step 1, raw material selection; Step 2, solution mixing; Step 3, co-precipitation processing; Step 4, treatment and screening; Step 5, pulling Coating; step six, high heat treatment; step seven, packaging and storage;

[0069] Wherein in above-mentioned step 1, according to the mass percentage content of each component respectively: 16% quartz glass substrate, 30% metallic indium, 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com