Composite material applied to electronic equipment and production method thereof

A composite material and electronic equipment technology, applied in the field of composite materials, can solve the problems of reducing the toughness of composite materials, low wear resistance and corrosion resistance, unfavorable processing and production, etc. High abrasion resistance and corrosion resistance, easy processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

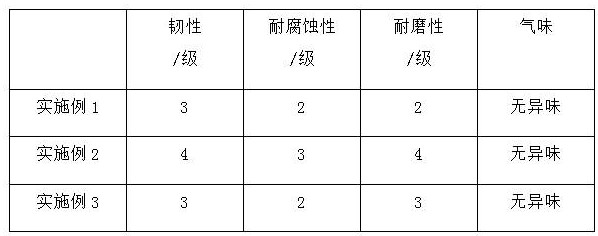

Embodiment 1

[0032] Composite materials used in electronic equipment, the formula includes: epoxy resin, graphite, silicon carbide, aluminum oxide, potassium permanganate, deionized water, ethylene acrylic acid copolymer, styrene, hydrogen peroxide, initiator and diluent, each The mass percentages of the components are: 16% epoxy resin, 20% graphite, 25% silicon carbide, 10% aluminum oxide, 4% potassium permanganate, 10% deionized water, 2% ethylene acrylic acid copolymer, Styrene 8%, hydrogen peroxide 1%, initiator 1% and thinner 3%.

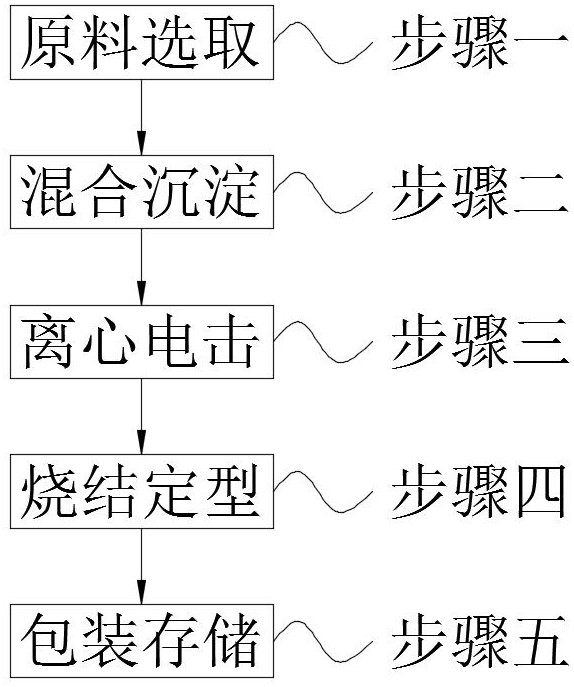

[0033] The production method of the composite material applied to the electronic equipment includes the following steps: Step 1, raw material selection; Step 2, mixed precipitation; Step 3, centrifugal electric shock; Step 4, sintering and shaping; Step 5, packaging and storage;

[0034] Wherein the above step 1, according to the mass percentage of each component is: epoxy resin 16%, graphite 20%, silicon carbide 25%, aluminum oxide 10%, potassium permangan...

Embodiment 2

[0049] Composite materials used in electronic equipment, the formula includes: epoxy resin, graphite, silicon carbide, aluminum oxide, potassium permanganate, deionized water, ethylene acrylic acid copolymer, styrene, hydrogen peroxide, initiator and diluent, each The mass percentages of the components are: 16% epoxy resin, 25% graphite, 20% silicon carbide, 10% aluminum oxide, 4% potassium permanganate, 10% deionized water, 2% ethylene acrylic acid copolymer, Styrene 8%, hydrogen peroxide 1%, initiator 1% and thinner 3%.

[0050] The production method of the composite material applied to the electronic equipment includes the following steps: Step 1, raw material selection; Step 2, mixed precipitation; Step 3, centrifugal electric shock; Step 4, sintering and shaping; Step 5, packaging and storage;

[0051] Wherein the above step 1, according to the mass percentage of each component is: epoxy resin 16%, graphite 25%, silicon carbide 20%, aluminum oxide 10%, potassium permanganat...

Embodiment 3

[0066] Composite materials used in electronic equipment, the formula includes: epoxy resin, graphite, silicon carbide, aluminum oxide, potassium permanganate, deionized water, ethylene acrylic acid copolymer, styrene, hydrogen peroxide, initiator and diluent, each The mass percentages of the components are: 16% epoxy resin, 30% graphite, 15% silicon carbide, 10% aluminum oxide, 4% potassium permanganate, 10% deionized water, 2% ethylene acrylic acid copolymer, Styrene 8%, hydrogen peroxide 1%, initiator 1% and thinner 3%.

[0067] The production method of the composite material applied to the electronic equipment includes the following steps: Step 1, raw material selection; Step 2, mixed precipitation; Step 3, centrifugal electric shock; Step 4, sintering and shaping; Step 5, packaging and storage;

[0068] Wherein the above step 1, according to the mass percentage of each component is: epoxy resin 16%, graphite 30%, silicon carbide 15%, aluminum oxide 10%, potassium permangan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com