Preparation method of self-cleaning external gray glaze

A gray and glaze technology, applied in the field of preparation of self-cleaning external gray glaze, can solve the problems of easy chemical corrosion and abrasion, complicated production process, stickiness and instability, etc. Simple, rigorous and easy to process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A self-cleaning exterior gray glaze, the formula includes: lead oxide, silicon dioxide, aluminum oxide, clay, borax, calcium oxide, magnesium oxide, porcelain powder, opacifying agent and strong fluxing agent, the mass of each component The percentages are: lead oxide 16%, silicon dioxide 25%, aluminum oxide 20%, clay 10%, borax 4%, calcium oxide 10%, magnesium oxide 3%, porcelain powder 10%, opacifying agent 1% and Strong Flux 1%.

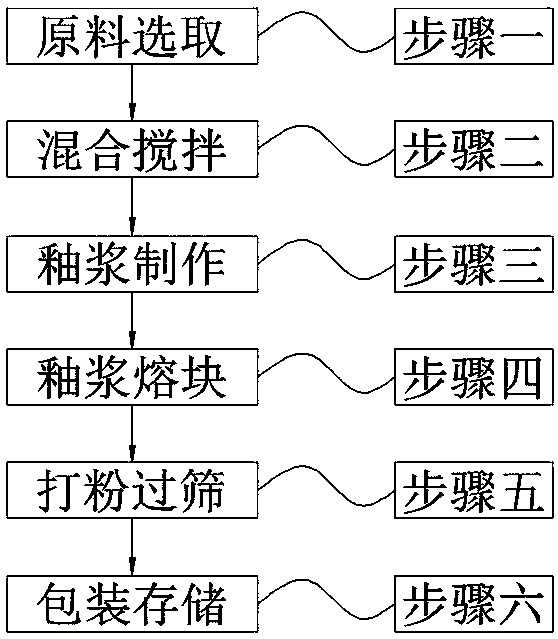

[0037] A method for preparing a self-cleaning exterior gray glaze, comprising the following steps: step 1, selecting raw materials; step 2, mixing and stirring; step 3, making glaze slurry; step 4, fritting the glaze slurry; step 5, beating powder and sieving; Step 6, packing and storing;

[0038] Wherein in the above-mentioned step one, according to the mass percentage content of each component is respectively: lead oxide 16%, silicon dioxide 25%, aluminum oxide 20%, clay 10%, borax 4%, calcium oxide 10%, oxide 3% of magnesium, 10% of po...

Embodiment 2

[0059] A self-cleaning exterior gray glaze, the formula includes: lead oxide, silicon dioxide, aluminum oxide, clay, borax, calcium oxide, magnesium oxide, porcelain powder, opacifying agent and strong fluxing agent, the mass of each component The percentages are: lead oxide 16%, silicon dioxide 25%, aluminum oxide 20%, clay 10%, borax 4%, calcium oxide 10%, magnesium oxide 3%, porcelain powder 10%, opacifying agent 1% and Strong Flux 1%.

[0060] A method for preparing a self-cleaning exterior gray glaze, comprising the following steps: step 1, selecting raw materials; step 2, mixing and stirring; step 3, making glaze slurry; step 4, fritting the glaze slurry; step 5, beating powder and sieving; Step 6, packing and storing;

[0061] Wherein in the above-mentioned step one, according to the mass percentage content of each component is respectively: lead oxide 16%, silicon dioxide 25%, aluminum oxide 20%, clay 10%, borax 4%, calcium oxide 10%, oxide 3% of magnesium, 10% of po...

Embodiment 3

[0082] A self-cleaning exterior gray glaze, the formula includes: lead oxide, silicon dioxide, aluminum oxide, clay, borax, calcium oxide, magnesium oxide, porcelain powder, opacifying agent and strong fluxing agent, the mass of each component The percentages are: lead oxide 16%, silicon dioxide 30%, aluminum oxide 15%, clay 10%, borax 4%, calcium oxide 10%, magnesium oxide 3%, porcelain powder 10%, opacifier 1% and Strong Flux 1%.

[0083] A method for preparing a self-cleaning exterior gray glaze, comprising the following steps: step 1, selecting raw materials; step 2, mixing and stirring; step 3, making glaze slurry; step 4, fritting the glaze slurry; step 5, beating powder and sieving; Step 6, packing and storing;

[0084] Wherein in the above-mentioned step one, according to the mass percentage content of each component is respectively: lead oxide 16%, silicon dioxide 30%, aluminum oxide 15%, clay 10%, borax 4%, calcium oxide 10%, oxide 3% of magnesium, 10% of porcelain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com