Formula of working solution in hydrogen peroxide production process

A production process and working fluid technology, applied in peroxide/peroxy hydrate/peroxyacid/superoxide/ozonide, chemical instruments and methods, inorganic chemistry, etc., can solve the problem of reducing hydrogen peroxide production rate, Can not promote hydrogen peroxide oxidation speed, unfavorable processing and production and other problems, to achieve the effect of favorable processing and production, convenient processing and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of formula of the working liquid of hydrogen peroxide production process, formula comprises: tetrahydronaphthalene, carrier, solvent, 2-methylcyclohexyl acetate, sulfurized oleic acid, brine and triethanolamine, and the mass percent of each component is respectively Is: 16% tetralin, 20% vehicle, 25% solvent, 10% 2-methylcyclohexyl acetate, 7% sulfurized oleic acid, 12% saline, 10% triethanolamine.

[0032] Among them, the carrier is 2-ethylanthraquinone and tetrahydro 2-ethylanthraquinone mixed according to 1:1; the solvent is trioctyl phosphate and heavy aromatic hydrocarbon mixed according to 1:2; the carrier mass concentration is 120- 160g / L; the solvent contains an aromatic hydrocarbon with a benzene ring and an alkyl substituent; the brine is a mixture of sodium chloride and water at a ratio of 1:4.

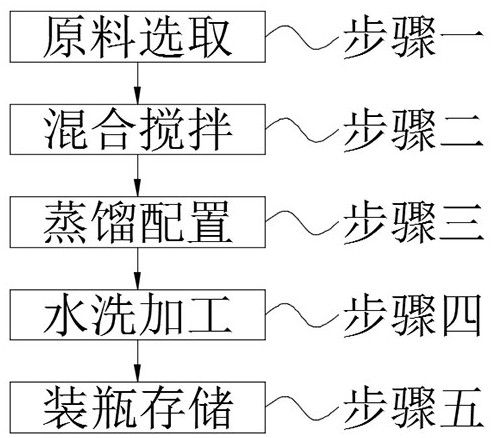

[0033] The preparation process of the formula of the working fluid in the hydrogen peroxide production process includes the following steps: Step 1, raw mater...

Embodiment 2

[0049]A kind of formula of the working liquid of hydrogen peroxide production process, formula comprises: tetrahydronaphthalene, carrier, solvent, 2-methylcyclohexyl acetate, sulfurized oleic acid, brine and triethanolamine, and the mass percent of each component is respectively Is: 16% tetralin, 25% vehicle, 20% solvent, 10% 2-methylcyclohexyl acetate, 7% sulfurized oleic acid, 12% saline, 10% triethanolamine.

[0050] Among them, the carrier is 2-ethylanthraquinone and tetrahydro 2-ethylanthraquinone mixed according to 1:1; the solvent is trioctyl phosphate and heavy aromatic hydrocarbon mixed according to 1:2; the carrier mass concentration is 120- 160g / L; the solvent contains an aromatic hydrocarbon with a benzene ring and an alkyl substituent; the brine is a mixture of sodium chloride and water at a ratio of 1:4.

[0051] The preparation process of the formula of the working fluid in the hydrogen peroxide production process includes the following steps: Step 1, raw materi...

Embodiment 3

[0067] A kind of formula of the working liquid of hydrogen peroxide production process, formula comprises: tetrahydronaphthalene, carrier, solvent, 2-methylcyclohexyl acetate, sulfurized oleic acid, brine and triethanolamine, and the mass percent of each component is respectively Is: 16% tetralin, 30% vehicle, 15% solvent, 10% 2-methylcyclohexyl acetate, 7% sulfurized oleic acid, 12% saline, 10% triethanolamine.

[0068] Among them, the carrier is 2-ethylanthraquinone and tetrahydro 2-ethylanthraquinone mixed according to 1:1; the solvent is trioctyl phosphate and heavy aromatic hydrocarbon mixed according to 1:2; the carrier mass concentration is 120- 160g / L; the solvent contains an aromatic hydrocarbon with a benzene ring and an alkyl substituent; the brine is a mixture of sodium chloride and water at a ratio of 1:4.

[0069] The preparation process of the formula of the working fluid in the hydrogen peroxide production process includes the following steps: Step 1, raw mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com