Double-surface-smooth ultra-thin electrolytic copper foil for lithium battery and preparation method thereof

A technology of electrolytic copper foil and lithium battery, applied in the field of copper foil, can solve problems such as unfavorable processing and production, unfavorable subsequent use, unfavorable user use, etc., and achieve the effects of favorable processing and production, convenient processing, and improved smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A double-sided glossy ultra-thin electrolytic copper foil for lithium batteries, the formula includes: pure water, copper raw materials, sulfuric acid, chromate, hydrogen peroxide, silane, initiator, resin substrate, catalyst, coupling agent, the composition of each component The mass percentages are: pure water 16%, copper raw material 20%, sulfuric acid 15%, chromate 10%, hydrogen peroxide 4%, silane 20%, initiator 3%, resin substrate 10%, catalyst 1% and Coupling agent 1%.

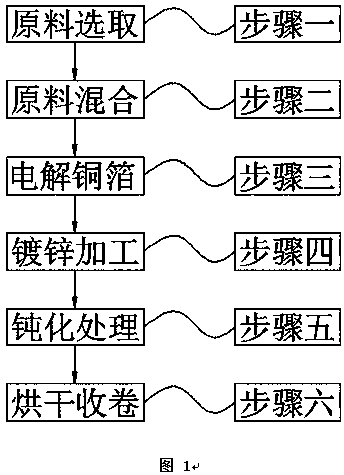

[0037] A method for preparing double-sided light ultra-thin electrolytic copper foil for lithium batteries, comprising the following steps: Step 1, raw material selection; Step 2, raw material mixing; Step 3, electrolytic copper foil; Step 4, galvanizing processing; Step 5, Passivation treatment; Step 6, drying and winding;

[0038] Wherein the above step 1, according to the mass percentage of each component is: pure water 16%, copper raw material 20%, sulfuric acid 15%, chromate 10%, hydrogen p...

Embodiment 2

[0058] A double-sided glossy ultra-thin electrolytic copper foil for lithium batteries, the formula includes: pure water, copper raw materials, sulfuric acid, chromate, hydrogen peroxide, silane, initiator, resin substrate, catalyst, coupling agent, the composition of each component The mass percentages are: pure water 16%, copper raw material 20%, sulfuric acid 15%, chromate 15%, hydrogen peroxide 4%, silane 15%, initiator 3%, resin substrate 10%, catalyst 1% and Coupling agent 1%.

[0059] A method for preparing double-sided light ultra-thin electrolytic copper foil for lithium batteries, comprising the following steps: Step 1, raw material selection; Step 2, raw material mixing; Step 3, electrolytic copper foil; Step 4, galvanizing processing; Step 5, Passivation treatment; Step 6, drying and winding;

[0060] Wherein the above-mentioned step 1, according to the mass percent content of each component is respectively: pure water 16%, copper raw material 20%, sulfuric acid 1...

Embodiment 3

[0080] A double-sided glossy ultra-thin electrolytic copper foil for lithium batteries, the formula includes: pure water, copper raw materials, sulfuric acid, chromate, hydrogen peroxide, silane, initiator, resin substrate, catalyst, coupling agent, the composition of each component The mass percentages are: pure water 16%, copper raw material 20%, sulfuric acid 15%, chromate 20%, hydrogen peroxide 4%, silane 10%, initiator 3%, resin substrate 10%, catalyst 1% and Coupling agent 1%.

[0081] A method for preparing double-sided light ultra-thin electrolytic copper foil for lithium batteries, comprising the following steps: Step 1, raw material selection; Step 2, raw material mixing; Step 3, electrolytic copper foil; Step 4, galvanizing processing; Step 5, Passivation treatment; Step 6, drying and winding;

[0082] Wherein the above step 1, according to the mass percentage of each component is: pure water 16%, copper raw material 20%, sulfuric acid 15%, chromate 20%, hydrogen p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com