Iron and steel enterprise contaminated soil remediation agent and use method thereof

A technology for contaminated soil and remediation agent, applied in the field of contaminated soil remediation agent in iron and steel enterprises, can solve the problems of inability to degrade and eliminate heavy metal elements in soil, time-consuming and laborious production process, increase of heavy metals in soil, etc. , the effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

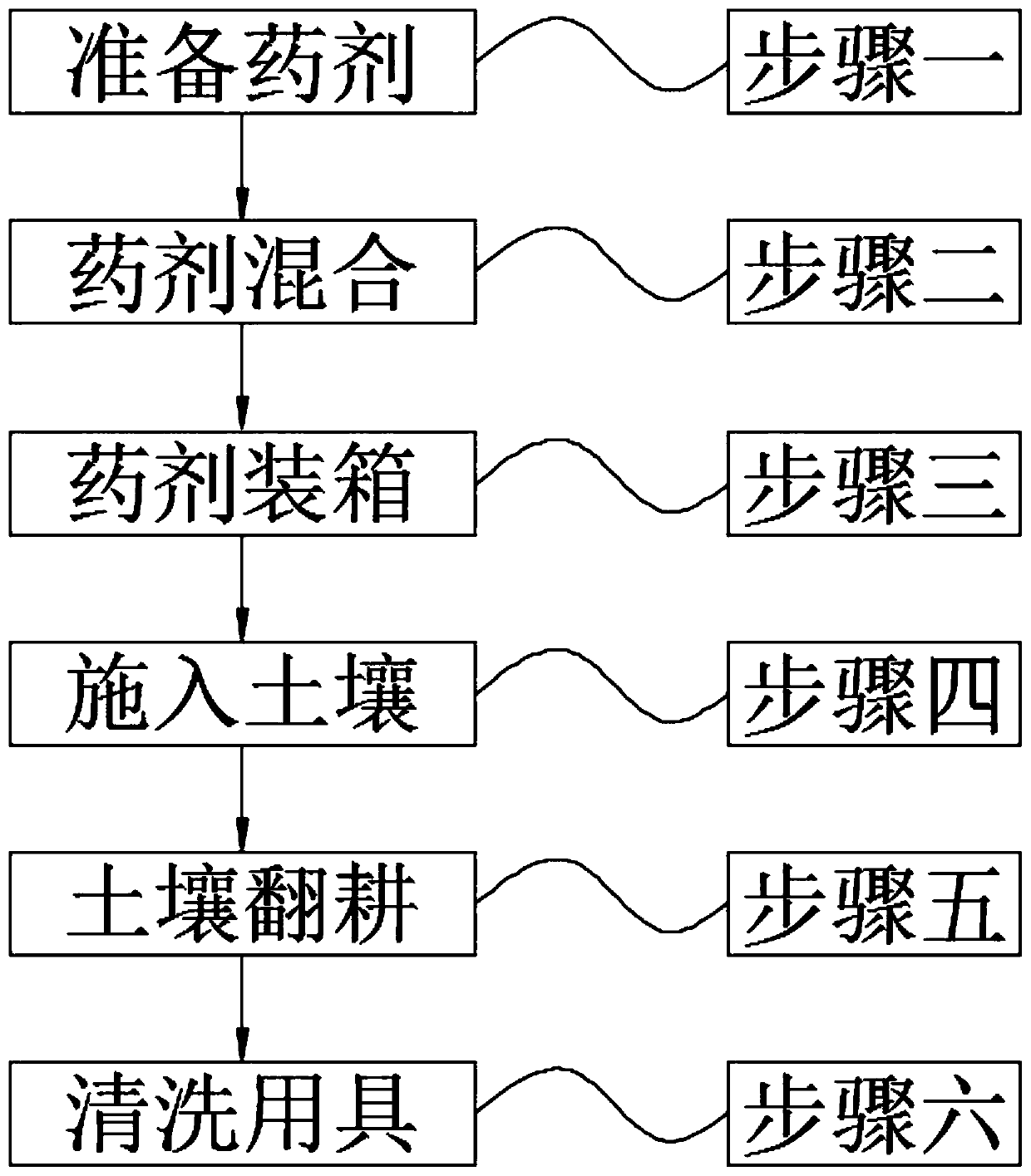

Method used

Image

Examples

Embodiment 1

[0025] A remediation agent for contaminated soil in iron and steel enterprises, the formula includes: quicklime, bentonite, superphosphate, calcium magnesium phosphate fertilizer, phosphate rock powder, biochar, organic fertilizer, corn stalks, catalyst and defoamer, the mass of each component is 100% The contents are: quicklime 16%, bentonite 20%, superphosphate 25%, calcium magnesium phosphate fertilizer 10%, phosphate rock powder 4%, biochar 10%, organic fertilizer 3%, corn straw 10%, catalyst 1% and defoamer 1%.

[0026] A kind of preparation method of iron and steel enterprise polluted soil remediation agent is, according to the mass percentage content of each component is respectively: quicklime 16%, bentonite 20%, calcium superphosphate 25%, calcium magnesium phosphate fertilizer 10%, phosphate rock powder 4% , 10% of biochar, 3% of organic fertilizer, 10% of corn stalk, 1% of catalyst and 1% of defoamer are selected, and weighed according to the sum of the weight perce...

Embodiment 2

[0038] A remediation agent for contaminated soil in iron and steel enterprises, the formula includes: quicklime, bentonite, superphosphate, calcium magnesium phosphate fertilizer, phosphate rock powder, biochar, organic fertilizer, corn stalks, catalyst and defoamer, the mass of each component is 100% The contents are: quicklime 16%, bentonite 25%, superphosphate 20%, calcium magnesium phosphate fertilizer 10%, phosphate rock powder 4%, biochar 10%, organic fertilizer 3%, corn straw 10%, catalyst 1% and defoamer 1%.

[0039] A kind of preparation method of iron and steel enterprise polluted soil remediation agent is, according to the mass percentage content of each component is respectively: quicklime 16%, bentonite 25%, calcium superphosphate 20%, calcium magnesium phosphate fertilizer 10%, phosphate rock powder 4% , 10% of biochar, 3% of organic fertilizer, 10% of corn stalk, 1% of catalyst and 1% of defoamer are selected, and weighed according to the sum of the weight perce...

Embodiment 3

[0051] A remediation agent for contaminated soil in iron and steel enterprises, the formula includes: quicklime, bentonite, superphosphate, calcium magnesium phosphate fertilizer, phosphate rock powder, biochar, organic fertilizer, corn stalks, catalyst and defoamer, the mass of each component is 100% The contents are: quicklime 16%, bentonite 30%, superphosphate 15%, calcium magnesium phosphate fertilizer 10%, phosphate rock powder 4%, biochar 10%, organic fertilizer 3%, corn straw 10%, catalyst 1% and defoamer 1%.

[0052] A kind of preparation method of iron and steel enterprise polluted soil remediation agent is, according to the mass percentage content of each component is respectively: quicklime 16%, bentonite 30%, superphosphate 15%, calcium magnesium phosphate fertilizer 10%, phosphate rock powder 4% , 10% of biochar, 3% of organic fertilizer, 10% of corn stalk, 1% of catalyst and 1% of defoamer are selected, and weighed according to the sum of the weight percentages b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com