Fruity lollypop and processing technology

A processing technology, lollipop technology, applied in the field of fruit lollipops, can solve the problems of human health hazards, loss of original fruit flavor, etc., and achieve the effect of simple and rigorous technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A fruit-flavored lollipop, the formula includes: white granulated sugar, water, glucose syrup, citric acid, tea polyphenols, concentrated fruit juice and natural pigments, and the mass percentages of each component are: 45% white granulated sugar, 28% % water, 15% glucose syrup, 1.3% citric acid, 3% tea polyphenols, 7.4% mango juice concentrate, 0.3% carotene.

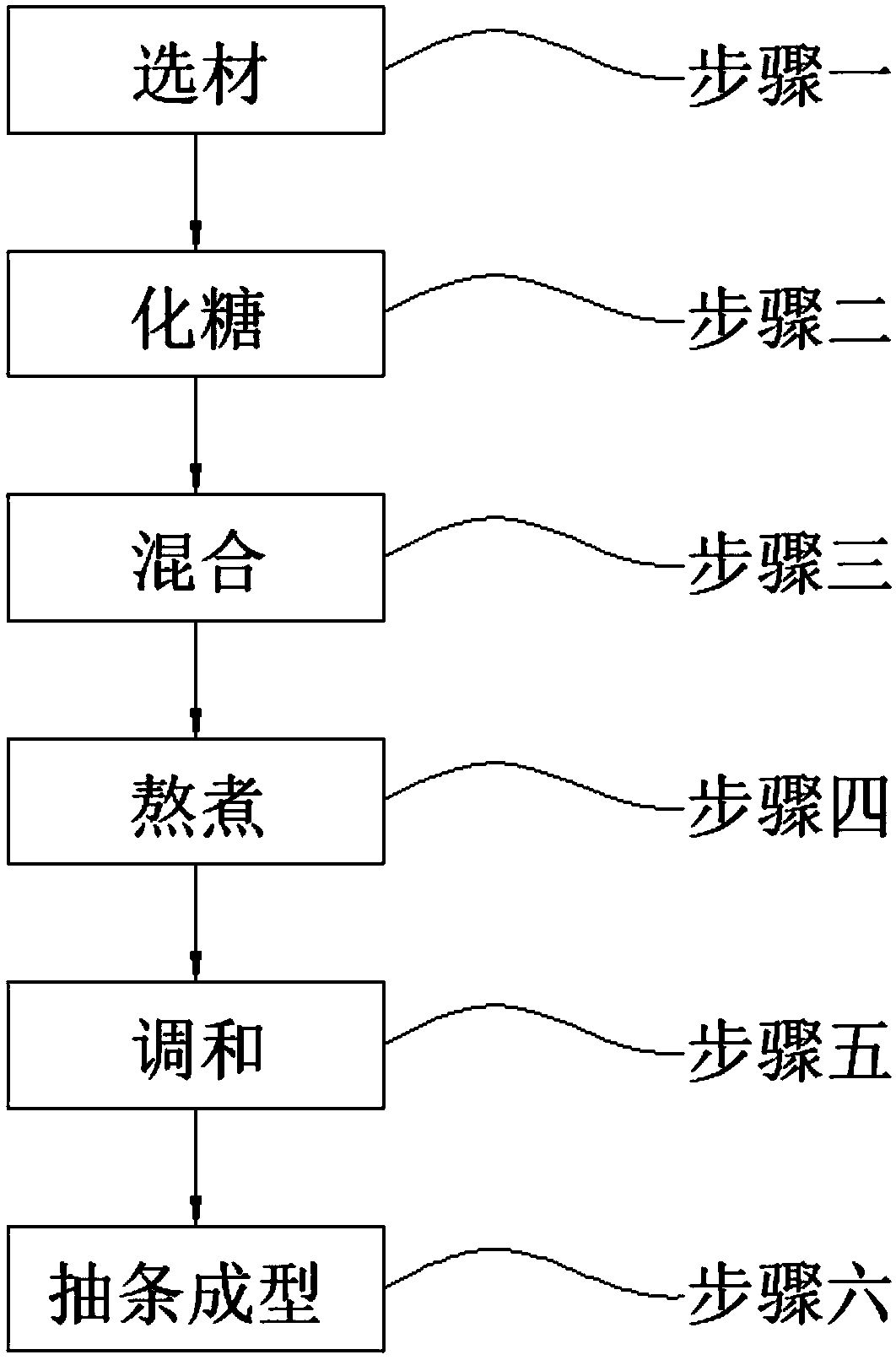

[0035] A processing technique for fruit-flavored lollipops, comprising the following steps: Step 1, material selection; Step 2, melting sugar; Step 3, mixing; Step 4, boiling; Step 5, blending; Step 6, drawing and forming;

[0036] Wherein the above-mentioned step 1, according to the mass percentage content of each component is respectively: 45% white granulated sugar, 28% water, 15% glucose syrup, 1.3% citric acid, 3% tea polyphenol, 7.4% Mango juice concentrate, 0.3% natural pigment are selected, and weighed according to the sum of weight percentages being 1;

[0037] Wherein in above-mentioned step 2, turnin...

Embodiment 2

[0054] A fruit-flavored lollipop, the formula includes: white granulated sugar, water, glucose syrup, citric acid, tea polyphenols, concentrated fruit juice and natural pigments, and the mass percentages of each component are: 44.5% white granulated sugar, 28% % water, 14% glucose syrup, 1.5% citric acid, 3.8% tea polyphenols, 8% blueberry juice concentrate, 0.2% gardenia blue.

[0055] A processing technique for fruit-flavored lollipops, comprising the following steps: Step 1, material selection; Step 2, melting sugar; Step 3, mixing; Step 4, boiling; Step 5, blending; Step 6, drawing and forming;

[0056] Wherein the above-mentioned step one, according to the mass percentage content of each component is respectively: 44.5% white granulated sugar, 28% water, 14% glucose syrup, 1.5% citric acid, 3.8% tea polyphenol, 8% Blueberry juice concentrate, 0.2% gardenia blue are weighed;

[0057] Wherein in above-mentioned step 2, turning sugar comprises the following steps:

[0058]...

Embodiment 3

[0074] A fruit-flavored lollipop, the formula includes: white granulated sugar, water, glucose syrup, citric acid, tea polyphenols, concentrated fruit juice and natural pigments, and the mass percentages of each component are: 46% white granulated sugar, 26.5% % water, 13% glucose syrup, 1.5% citric acid, 3.8% tea polyphenols, 9% watermelon juice concentrate, 0.2% monascus red.

[0075] A processing technique for fruit-flavored lollipops, comprising the following steps: Step 1, material selection; Step 2, melting sugar; Step 3, mixing; Step 4, boiling; Step 5, blending; Step 6, drawing and forming;

[0076] Wherein the above-mentioned step 1, according to the mass percentage content of each component is respectively: 46% white granulated sugar, 26.5% water, 13% glucose syrup, 1.5% citric acid, 3.8% tea polyphenol, 9% Watermelon juice concentrate, 0.2% Monascus Red are weighed;

[0077] Wherein in above-mentioned step 2, turning sugar comprises the following steps:

[0078] 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com