Method for removing grease solvent residues by supergravity rotating bed gas extraction method

A technology of supergravity rotating bed and extraction method, applied in the fields of cosmetics, chemical industry, medicine and food, to achieve the effect of easy installation, low operating temperature and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

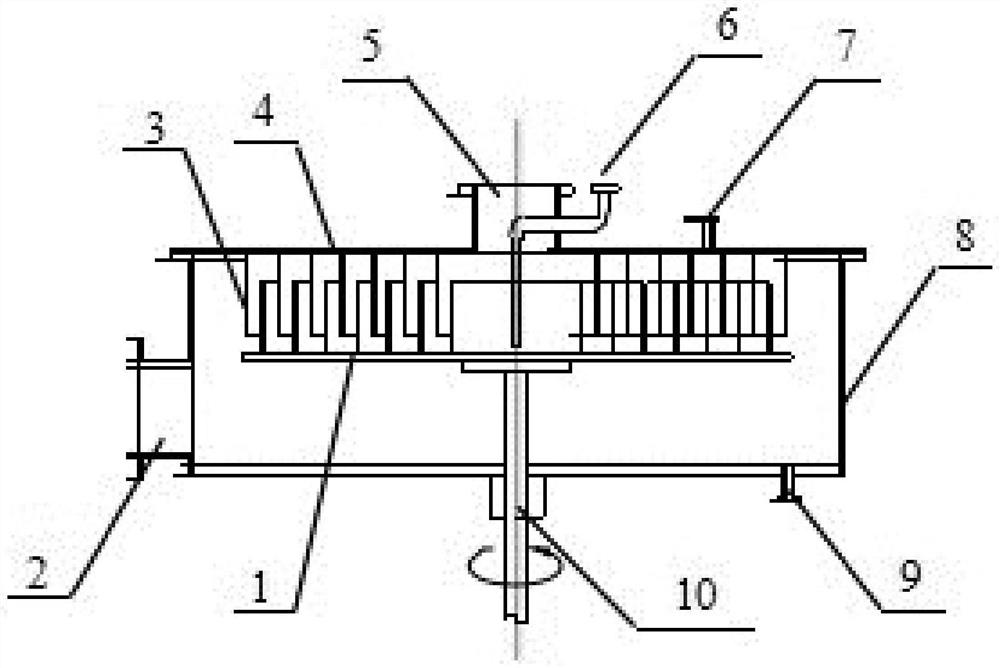

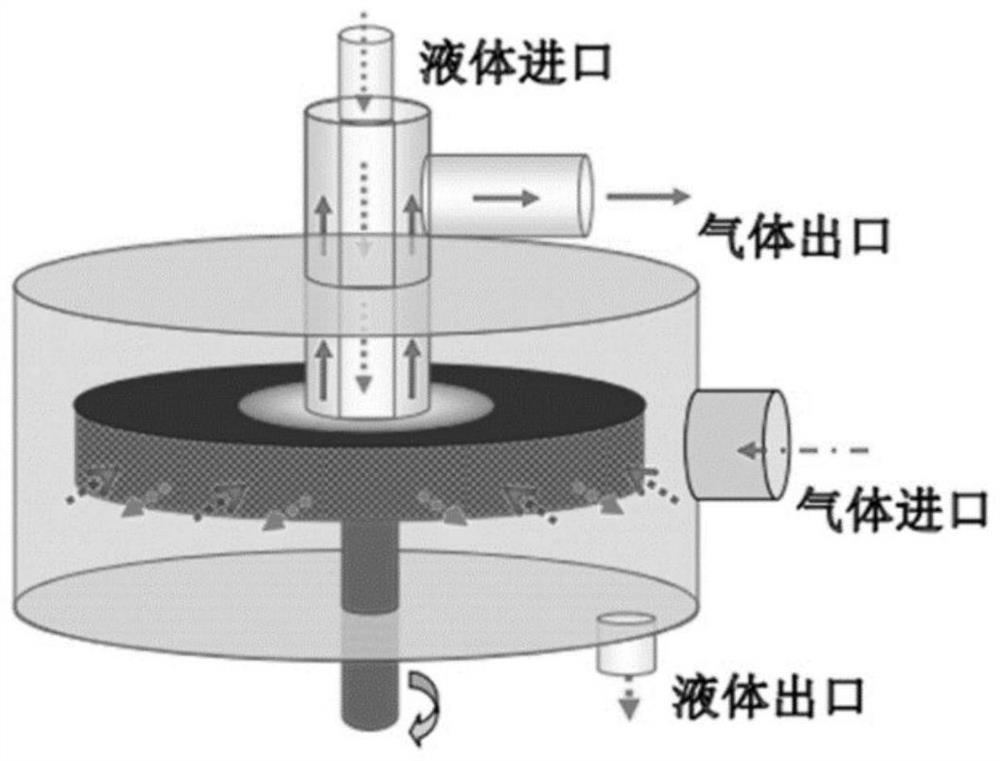

[0051] The three-layer baffled supergravity rotating bed is driven to reach the rated speed, and food-grade carbon dioxide with a pressure of 0.1 MPa is passed into the supergravity rotating bed from the gas inlet pipe (2) as the extraction gas, and the flow rate is set to 40L / h , 120L of residual No. 6 light gasoline (mainly n-hexane and cyclohexane) soybean oil in the raw material storage tank is pumped into the supergravity rotating bed from the liquid feed pipe (6), and the flow rate is set to 100L / h; Recycling treatment, solvent residual detection results: n-hexane is 1.5ppm; cyclohexane is 1ppm.

Embodiment 2

[0053]The three-layer baffled supergravity rotating bed is driven to reach the rated speed, and the food-grade nitrogen with a pressure of 0.1MPa is introduced into the supergravity rotating bed from the gas inlet pipe (2) as the extraction gas, and the flow rate is set to 50L / h , pump the peanut oil liquid feed pipe (6) of 120L of No. 6 light gasoline (mainly n-hexane and cyclohexane) remaining in the raw material storage tank into the supergravity rotating bed, and the flow rate is set to 100L / h; after four cycles Treatment, solvent residue detection results: n-hexane was not detected; cyclohexane was not detected.

Embodiment 3

[0055] The three-layer baffled supergravity rotating bed is driven to reach the rated speed, and the food-grade carbon dioxide with a pressure of 0.1MPa is passed into the supergravity rotating bed from the gas inlet pipe (2) as the extraction gas, and the flow rate is set to 60L / h , the fullerene linseed oil solution containing 120L of residual o-xylene in the raw material storage tank is pumped from the liquid feed pipe (6) into the supergravity rotating bed, and the flow rate is set to 100L / h; Test results: o-xylene was not detected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com