Molybdenum step target and manufacturing method thereof

A step and frame technology, which is applied in the field of molybdenum step target and its manufacturing, can solve the problems of high molybdenum hardness, difficult molybdenum step target processing and forming, and poor machining performance, so as to improve confidence, facilitate picking, and prevent part deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

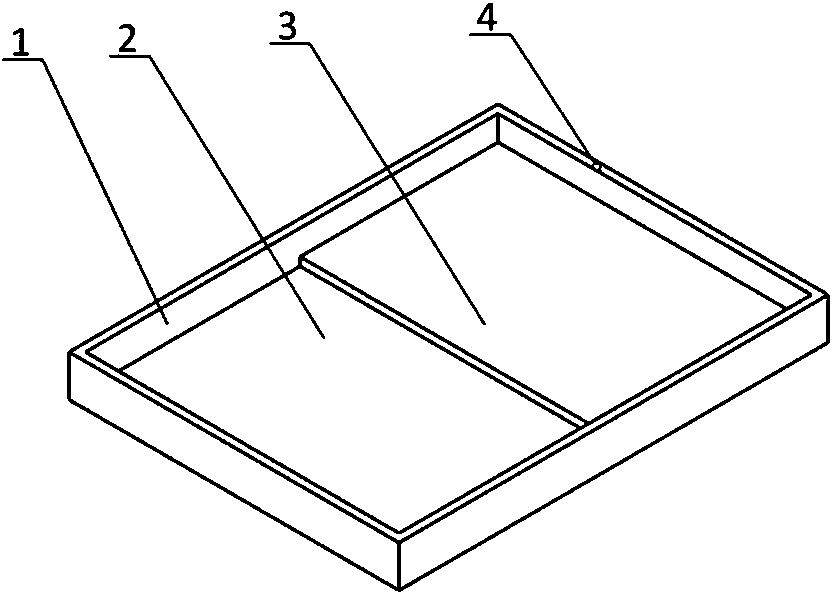

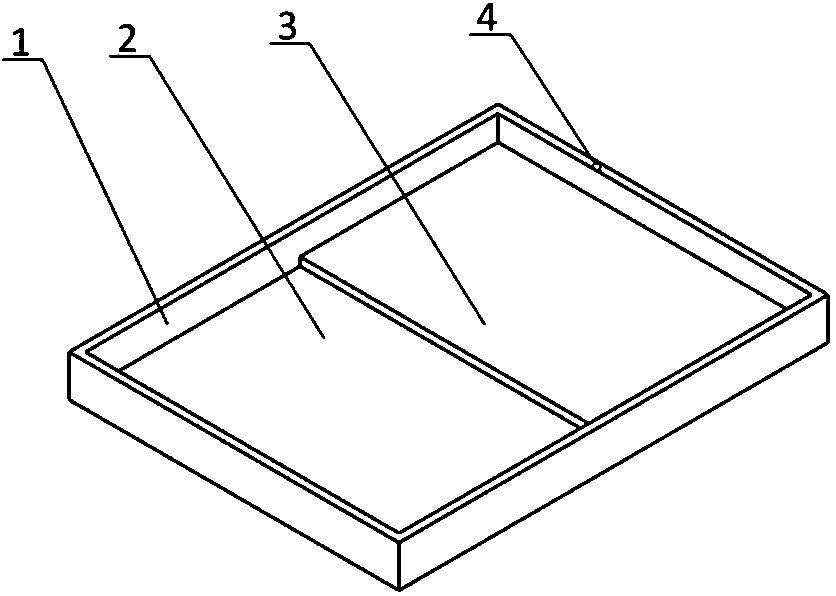

[0028] The outer dimension of the molybdenum step target prepared in this example is 10000 μm in length × 10000 μm in width, the frame width of the molybdenum step target is 100 μm, the inner base is 4900 μm in length × 9800 μm in width × 30 μm in thickness, and the steps are 4900 μm in length × 9800 μm in width × 40 μm in thickness . Its preparation process is as follows:

[0029] a. Using rolled molybdenum thin film, the molybdenum thin film is 100 μm thick, and processed into 10000 μm×10000 μm molybdenum blank by slow wire cutting;

[0030] b. Measure the thickness value H1 of the molybdenum blank by laser confocal measuring device;

[0031] c. Clamp the metal block with flat surface on the electric discharge milling machine;

[0032] d. Process the horizontal plane on the surface of the metal block by electric discharge milling, the size of the horizontal plane is 12000 μm × 12000 μm, and at the same time, the coordinate value H2 of the horizontal plane of the metal bloc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com