Flax interwoven fabric with built-in polylactic acid material and processing technology thereof

A polylactic acid material and processing technology, which is applied in textiles, fabrics, textiles and papermaking, etc., can solve the problems of unfavorable user health, low color fastness, unfavorable fabric appearance, etc., and achieves convenient cleaning, low cost, and low odor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

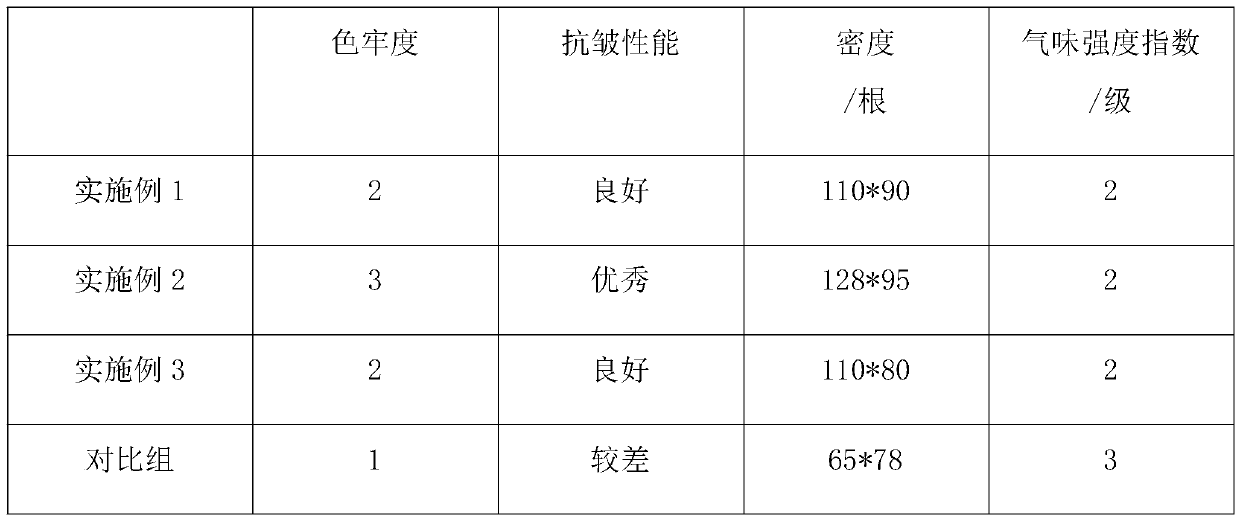

Embodiment 1

[0028] A linen interwoven fabric with built-in polylactic acid material, the formula includes: lactic acid monomer, linen, cotton fiber, viscose filament fiber, polyester fiber, milk protein fiber, dehydrating agent, catalyst and dyeing agent, the quality of each component The percentages are: 15% lactic acid monomer, 27% flax, 8% cotton fiber, 20% viscose filament fiber, 15% polyester fiber, 5% milk protein fiber, 5% Dehydrating agent, 3% catalyst and 2% coloring agent.

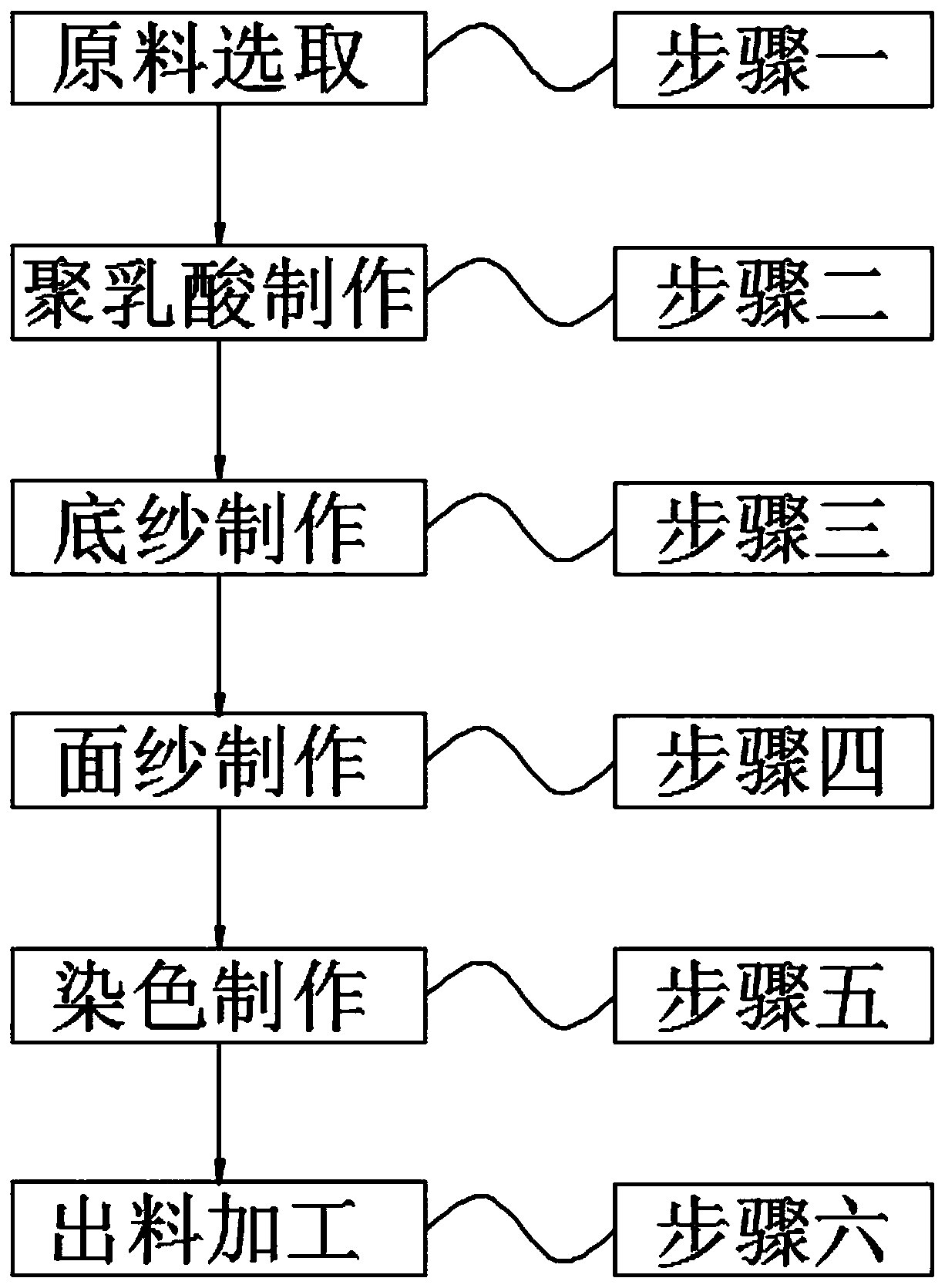

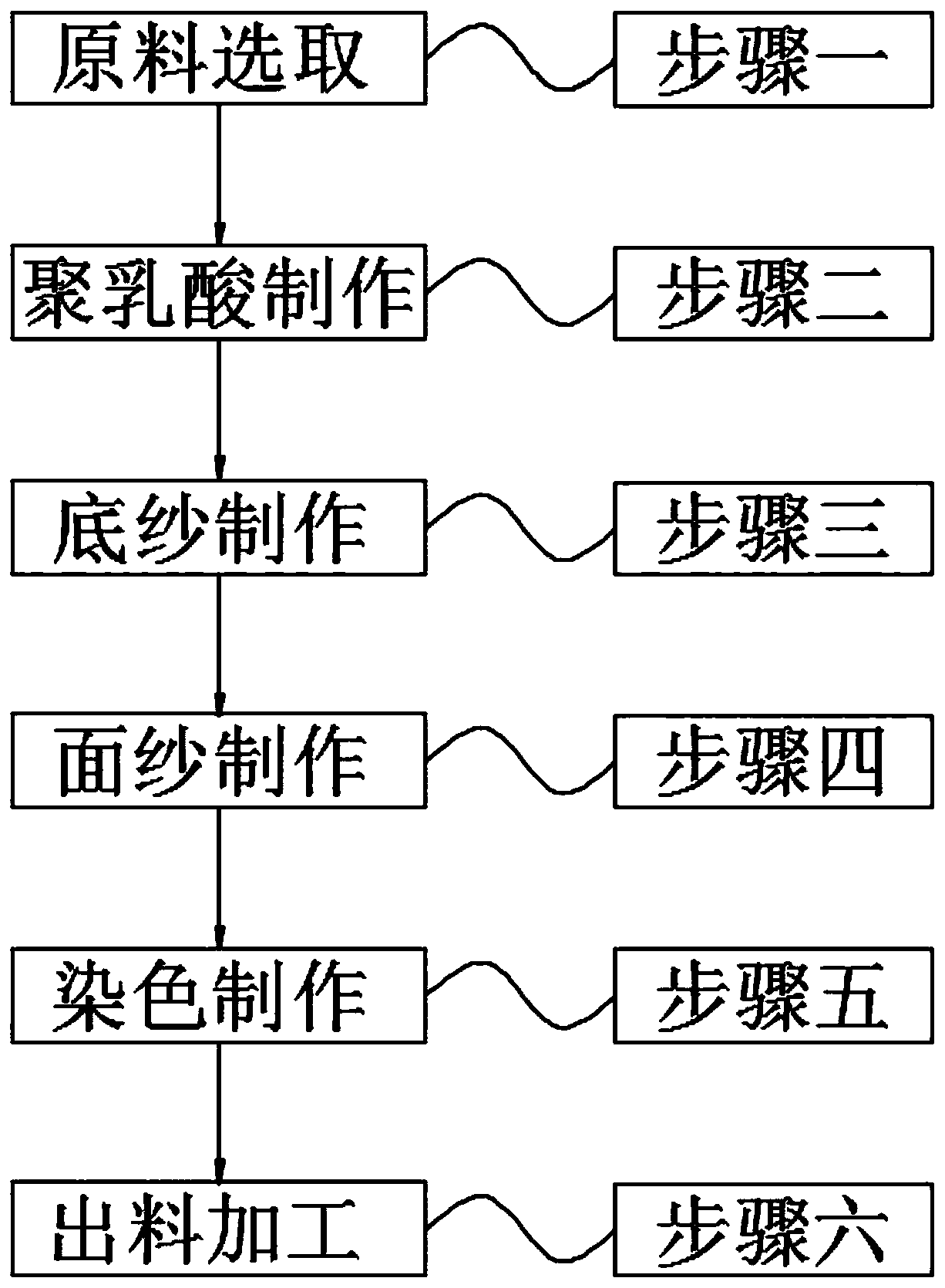

[0029] A processing technology of flax interwoven fabric with built-in polylactic acid material, comprising the following steps: Step 1, raw material selection; Step 2, polylactic acid production; Step 3, bottom yarn production; Step 4, veil production; Step 5, dyeing production; Step 6, discharging processing;

[0030] Wherein in the above-mentioned step 1, according to the mass percentage content of each component is respectively: 15% lactic acid monomer, 27% flax, 8% cotton fiber, 20% viscose filament fi...

Embodiment 2

[0042] A linen interwoven fabric with built-in polylactic acid material, the formula includes: lactic acid monomer, linen, cotton fiber, viscose filament fiber, polyester fiber, milk protein fiber, dehydrating agent, catalyst and dyeing agent, the quality of each component The percentages are: 20% lactic acid monomer, 27% flax, 8% cotton fiber, 15% viscose filament fiber, 15% polyester fiber, 5% milk protein fiber, 5% Dehydrating agent, 3% catalyst and 2% coloring agent.

[0043] A processing technology of flax interwoven fabric with built-in polylactic acid material, comprising the following steps: Step 1, raw material selection; Step 2, polylactic acid production; Step 3, bottom yarn production; Step 4, veil production; Step 5, dyeing production; Step 6, discharging processing;

[0044] Wherein in the above-mentioned step 1, according to the mass percentage content of each component is respectively: 20% lactic acid monomer, 27% flax, 8% cotton fiber, 15% viscose filament fi...

Embodiment 3

[0056] A linen interwoven fabric with built-in polylactic acid material, the formula includes: lactic acid monomer, linen, cotton fiber, viscose filament fiber, polyester fiber, milk protein fiber, dehydrating agent, catalyst and dyeing agent, the quality of each component The percentages are: 25% lactic acid monomer, 27% flax, 8% cotton fiber, 10% viscose filament fiber, 15% polyester fiber, 5% milk protein fiber, 5% Dehydrating agent, 3% catalyst and 2% coloring agent.

[0057] A processing technology of flax interwoven fabric with built-in polylactic acid material, comprising the following steps: Step 1, raw material selection; Step 2, polylactic acid production; Step 3, bottom yarn production; Step 4, veil production; Step 5, dyeing production; Step 6, discharging processing;

[0058] Wherein in the above-mentioned step 1, according to the mass percentage content of each component is respectively: 25% lactic acid monomer, 27% flax, 8% cotton fiber, 10% viscose filament fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com