Preparation method of chitosan-based uvioresistant finishing agent

An anti-ultraviolet and chitosan technology, applied in fiber processing, biochemical fiber processing, textiles and papermaking, etc., can solve the problems of expensive raw materials for anti-ultraviolet finishing agents, reduced anti-ultraviolet performance, unfavorable processing and production, etc. Ultraviolet performance, conducive to processing and production, simple and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A chitosan-based anti-ultraviolet finishing agent, the formula includes: ammonium polyphosphate, chitosan, sodium lactate, 2,4-dihydroxybenzophenone, 4-nitro-1, titanium dioxide, sodium hydroxide, toluene, Citric acid, ethanol and dispersant, the mass percent composition of each component is respectively: 16% ammonium polyphosphate, 30% chitosan, 15% sodium lactate, 10% 2,4-dihydroxybenzidine Ketone, 4% 4-nitro-1, 10% titanium dioxide, 2% sodium hydroxide, 8% toluene, 1% citric acid, 1% ethanol and 3% dispersant.

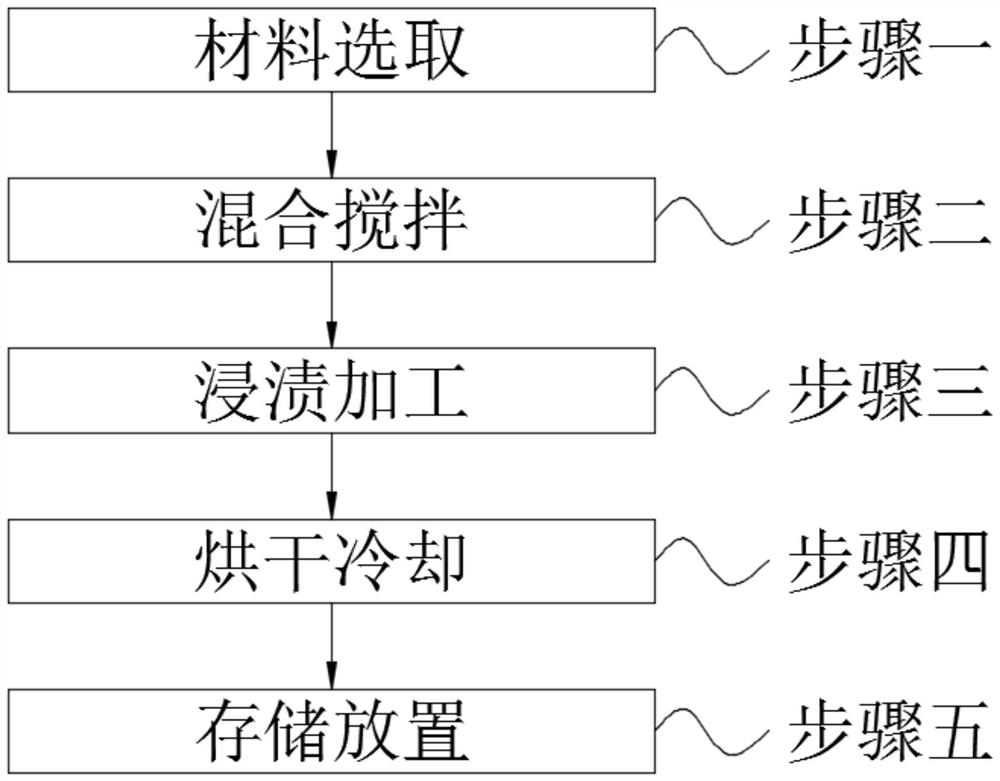

[0031] A method for preparing a chitosan-based anti-ultraviolet finishing agent, comprising the following steps: step 1, material selection; step 2, mixing and stirring; step 3, dipping processing; step 4, drying and cooling; step 5, storing and placing;

[0032] Wherein in the above-mentioned step one, according to the mass percent of each component, it is respectively: 16% ammonium polyphosphate, 30% chitosan, 15% sodium lactate, 10% 2,4-dihydroxybenzopheno...

Embodiment 2

[0046] A chitosan-based anti-ultraviolet finishing agent, the formula includes: ammonium polyphosphate, chitosan, sodium lactate, 2,4-dihydroxybenzophenone, 4-nitro-1, titanium dioxide, sodium hydroxide, toluene, Citric acid, ethanol and dispersant, the mass percent composition of each component is respectively: 16% ammonium polyphosphate, 25% chitosan, 20% sodium lactate, 10% 2,4-dihydroxybenzidine Ketone, 4% 4-nitro-1, 10% titanium dioxide, 2% sodium hydroxide, 8% toluene, 1% citric acid, 1% ethanol and 3% dispersant.

[0047] A method for preparing a chitosan-based anti-ultraviolet finishing agent, comprising the following steps: Step 1, material selection; Step 2, mixing and stirring; Step 3, dipping processing; Step 4, drying and cooling; Step 5, storing and placing;

[0048]Wherein in the above-mentioned step one, according to the mass percent content of each component is respectively: 16% ammonium polyphosphate, 25% chitosan, 20% sodium lactate, 10% 2,4-dihydroxybenzoph...

Embodiment 3

[0062] A chitosan-based anti-ultraviolet finishing agent, the formula includes: ammonium polyphosphate, chitosan, sodium lactate, 2,4-dihydroxybenzophenone, 4-nitro-1, titanium dioxide, sodium hydroxide, toluene, Citric acid, ethanol and dispersant, the mass percent content of each component is respectively: 16% ammonium polyphosphate, 20% chitosan, 25% sodium lactate, 10% 2,4-dihydroxybenzidine Ketone, 4% 4-nitro-1, 10% titanium dioxide, 2% sodium hydroxide, 8% toluene, 1% citric acid, 1% ethanol and 3% dispersant.

[0063] A method for preparing a chitosan-based anti-ultraviolet finishing agent, comprising the following steps: step 1, material selection; step 2, mixing and stirring; step 3, dipping processing; step 4, drying and cooling; step 5, storing and placing;

[0064] Wherein in the above-mentioned step one, according to the mass percentage content of each component is respectively: 16% ammonium polyphosphate, 20% chitosan, 25% sodium lactate, 10% 2,4-dihydroxybenzoph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com