Preparation method of carbon-coated graphite negative electrode material

A graphite negative electrode and carbon-coated technology, which is applied in the field of preparation of carbon-coated graphite negative electrode materials, can solve problems such as the inability to significantly improve the electrochemical performance of graphite, the inability to eliminate graphite surface defects and impurities, and unfavorable graphite processing and production. Achieve the effects of improving electrochemical performance, facilitating processing and production, and facilitating processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

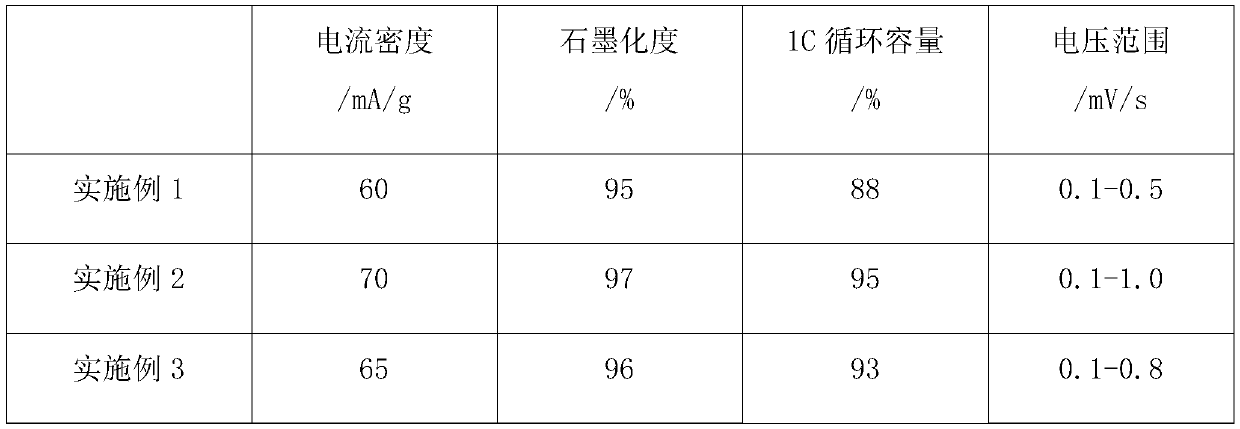

Embodiment 1

[0036] A carbon-coated graphite negative electrode material, the formula includes: graphite, graphene, ionic liquid, epoxy resin, polyvinylidene fluoride, ethanol, pickling mixed solution, quinone, catalyst and initiator, the mass of each component The percentages are: graphite 16%, graphene 20%, ionic liquid 25%, epoxy resin 10%, polyvinylidene fluoride 4%, ethanol 10%, pickling mixture 3%, quinone 10%, Catalyst 1% and Initiator 1%.

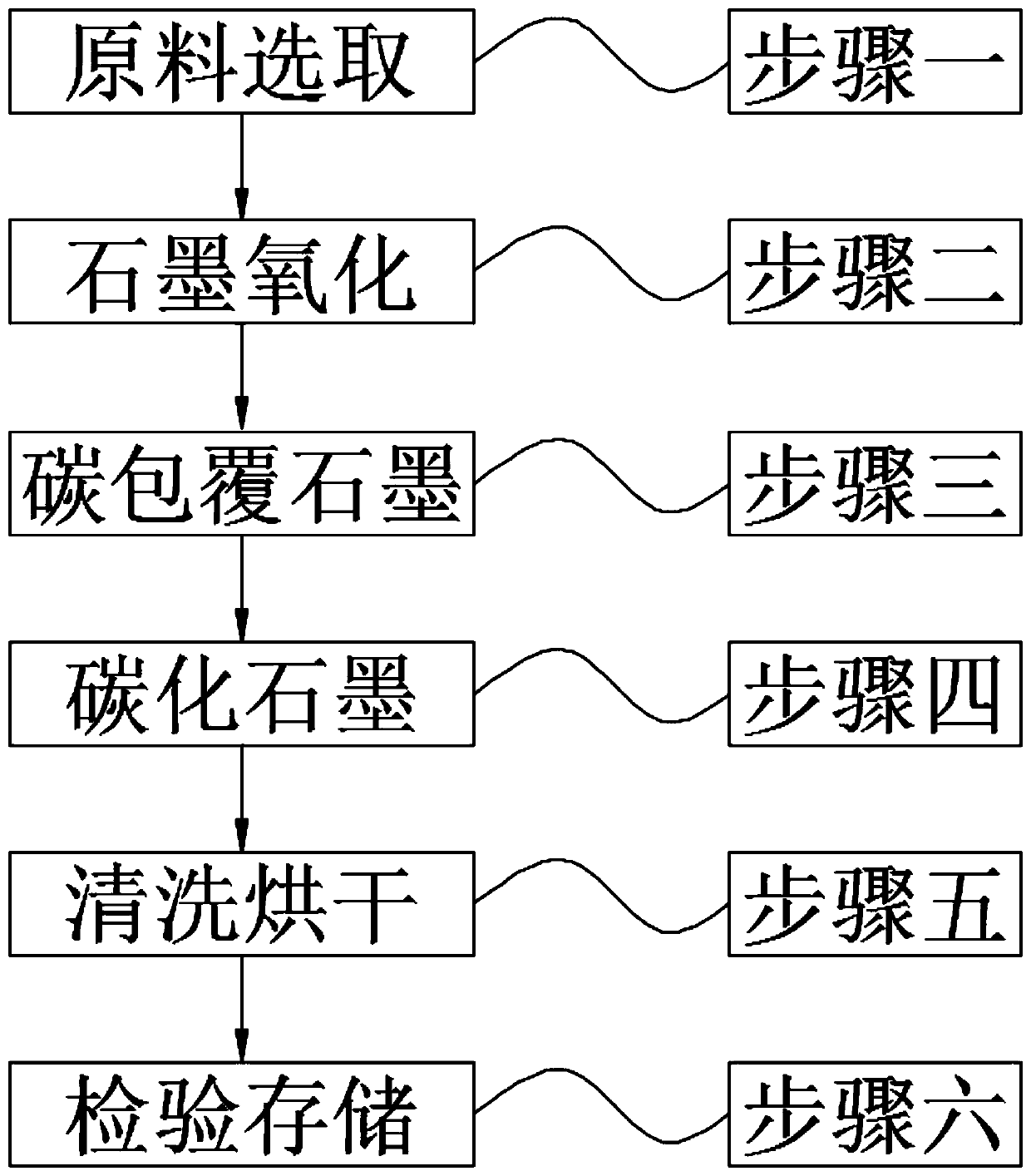

[0037] A method for preparing a carbon-coated graphite negative electrode material, comprising the following steps: Step 1, raw material selection; Step 2, graphite oxidation; Step 3, carbon-coated graphite; Step 4, carbonized graphite; Step 5, cleaning and drying; Sixth, inspection and storage;

[0038] Wherein the above-mentioned step 1, according to the mass percentage content of each component is respectively: graphite 16%, graphene 20%, ionic liquid 25%, epoxy resin 10%, polyvinylidene fluoride 4%, ethanol 10%, acid 3% of washing mixed so...

Embodiment 2

[0059] A carbon-coated graphite negative electrode material, the formula includes: graphite, graphene, ionic liquid, epoxy resin, polyvinylidene fluoride, ethanol, pickling mixed solution, quinone, catalyst and initiator, the mass of each component The percentages are: graphite 16%, graphene 25%, ionic liquid 20%, epoxy resin 10%, polyvinylidene fluoride 4%, ethanol 10%, pickling mixture 3%, quinone 10%, Catalyst 1% and Initiator 1%.

[0060] A method for preparing a carbon-coated graphite negative electrode material, comprising the following steps: Step 1, raw material selection; Step 2, graphite oxidation; Step 3, carbon-coated graphite; Step 4, carbonized graphite; Step 5, cleaning and drying; Sixth, inspection and storage;

[0061] Wherein the above-mentioned step 1, according to the mass percentage content of each component is respectively: graphite 16%, graphene 25%, ionic liquid 20%, epoxy resin 10%, polyvinylidene fluoride 4%, ethanol 10%, acid 3% of washing mixed so...

Embodiment 3

[0082] A carbon-coated graphite negative electrode material, the formula includes: graphite, graphene, ionic liquid, epoxy resin, polyvinylidene fluoride, ethanol, pickling mixed solution, quinone, catalyst and initiator, the mass of each component The percentages are: graphite 16%, graphene 30%, ionic liquid 15%, epoxy resin 10%, polyvinylidene fluoride 4%, ethanol 10%, pickling mixture 3%, quinone 10%, Catalyst 1% and Initiator 1%.

[0083] A method for preparing a carbon-coated graphite negative electrode material, comprising the following steps: Step 1, raw material selection; Step 2, graphite oxidation; Step 3, carbon-coated graphite; Step 4, carbonized graphite; Step 5, cleaning and drying; Sixth, inspection and storage;

[0084] Wherein the above-mentioned step 1, according to the mass percentage content of each component is respectively: graphite 16%, graphene 30%, ionic liquid 15%, epoxy resin 10%, polyvinylidene fluoride 4%, ethanol 10%, acid 3% of washing mixed so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com