Insulating heat-conducting additive, insulating heat-conducting material, preparation method of insulating heat-conducting material and light emitting diode

An insulating and thermally conductive and additive technology is applied in the field of insulating and thermally conductive materials and their preparation, as well as in the field of insulating and thermally conductive additives, and can solve the problems of reduced heat conduction efficiency and poor thermal conductivity of insulating and thermally conductive materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

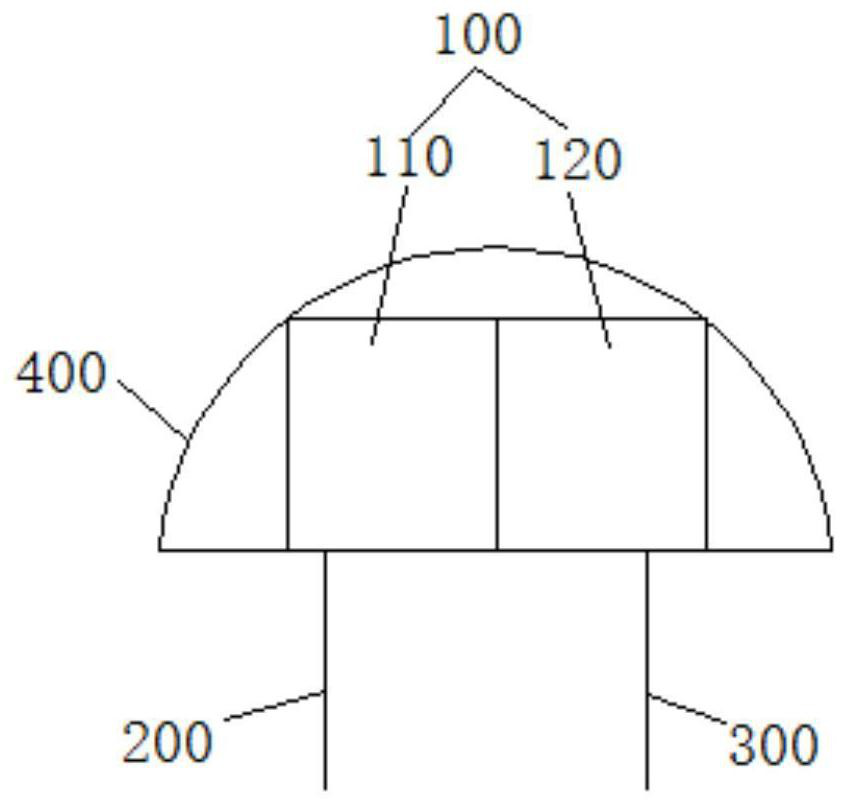

[0030] In order to improve the thermal conductivity of the insulating and thermally conductive material and improve the heat dissipation efficiency of the LED, an embodiment of the present invention provides an insulating and thermally conductive additive. The insulating and heat-conducting additive includes zero-dimensional insulating and heat-conducting fillers, one-dimensional insulating and heat-conducting fillers and two-dimensional insulating and heat-conducting fillers. The zero-dimensional insulating and heat-conducting filler is connected with a first group. The one-dimensional insulating and heat-conducting filler is connected with a second group. A third group is connected to the two-dimensional insulating and heat-conducting filler. Both the first group and the third group can undergo a cross-linking reaction with the second group, so that a three-dimensional insulating and heat-conducting network is formed among the zero-dimensional insulating and heat-conducting...

Embodiment approach 2

[0051] This embodiment provides an insulating and heat-conducting material. The insulating and heat-conducting material includes a polymer matrix and the above-mentioned insulating and heat-conducting additives.

[0052] Compared with the prior art, the beneficial effect of the insulating and heat-conducting material provided by the present invention is the same as that of the above-mentioned insulating and heat-conducting additive, which will not be repeated here.

[0053] Specifically, the mass ratio of the polymer matrix to the insulating and heat-conducting additive is (30:70)˜(65:35). At this time, the insulating and heat-conducting additive can be fully dispersed in the polymer matrix, so that a three-dimensional insulating and heat-conducting network can be constructed in the polymer matrix, and the heat-conducting performance of the insulating and heat-conducting material can be further improved. At the same time, it can also ensure that the insulating and heat-conduc...

Embodiment approach 3

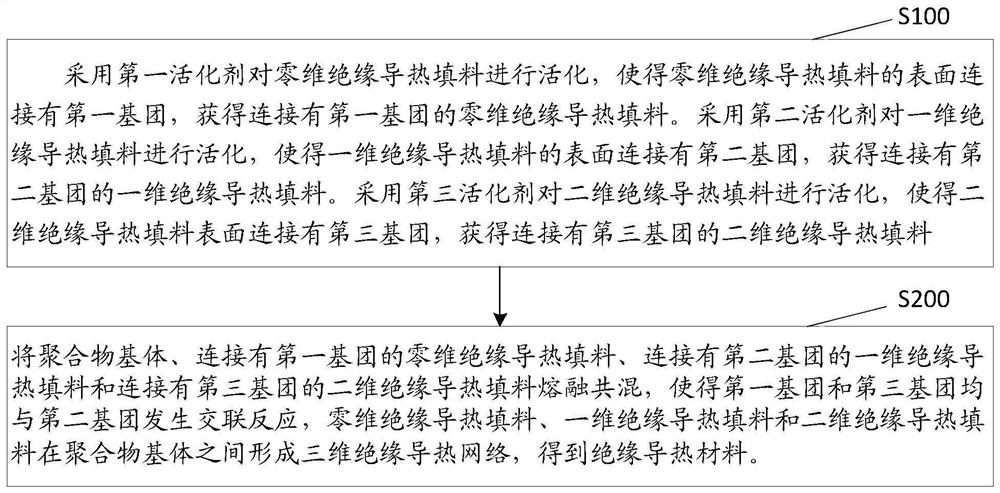

[0057] This embodiment provides a method for preparing an insulating and heat-conducting material. see figure 2 , the preparation method of the insulating and heat-conducting material comprises:

[0058] S200: Melt and blend the polymer matrix, the zero-dimensional insulating and heat-conducting filler connected with the first group, the one-dimensional insulating and heat-conducting filler connected with the second group, and the two-dimensional insulating and heat-conducting filler connected with the third group, so that Both the first group and the third group undergo a crosslinking reaction with the second group, and the zero-dimensional insulating and thermally conductive filler, the one-dimensional insulating and thermally conductive filler, and the two-dimensional insulating and thermally conductive filler form a three-dimensional insulating and thermally conductive network between the polymer matrix, and the obtained Insulating and thermally conductive material.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com