Pretreatment method of zircon powder and preparation method of vanadium zirconium blue material

The technology of vanadium zirconium blue material and zircon powder is applied in the field of pigment production, which can solve the problems of insufficient purity and activity of vanadium zirconium blue pigment, low reactivity of zircon powder and high impurity content, so as to make full use of raw materials, The effect of improving conversion rate and reducing reaction impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

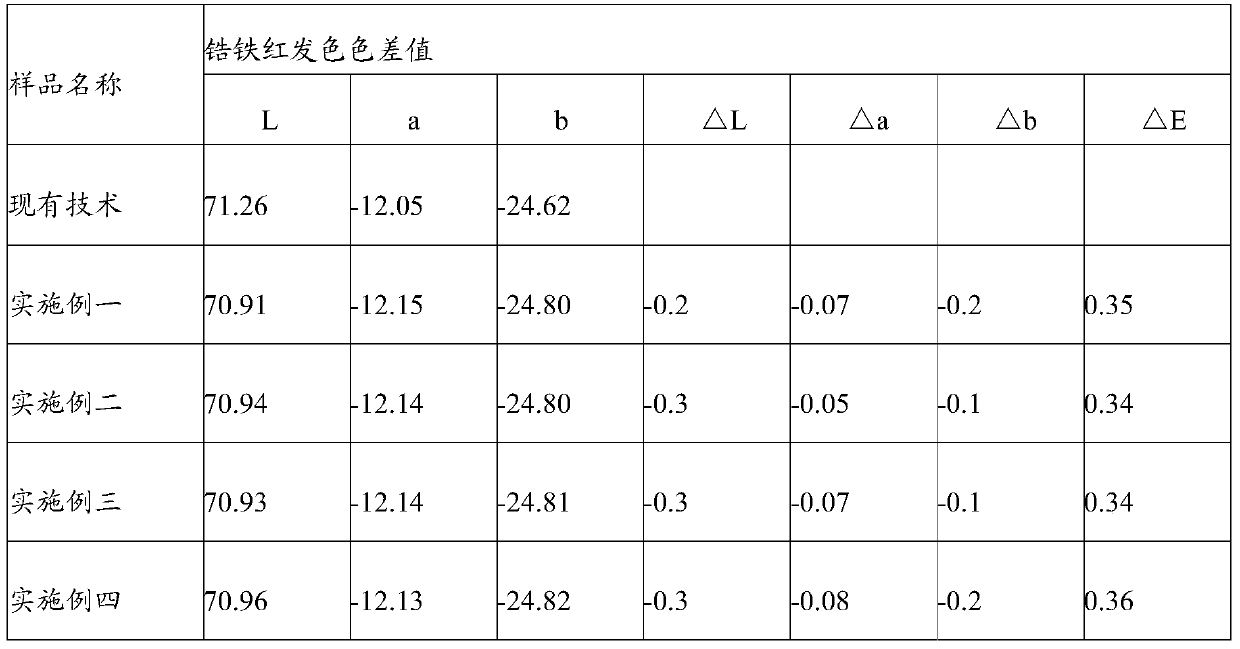

[0015] The present invention also provides a method for preparing vanadium-zirconium blue material. The zircon powder, vanadium pentoxide and sodium chloride pretreated by the above-mentioned zircon powder pretreatment method are mixed to obtain a mixture, and then the The mixture is heated at a uniform speed to a temperature of 800-900° C., the heating time is 8-11 hours, the temperature of the mixture is maintained at 800-900° C. for 1-1.5 hours, and then cooled to obtain a vanadium-zirconium blue material.

[0016] As can be seen from the foregoing description, the beneficial effects of the present invention are:

[0017] (1) The pretreatment method of zircon powder of the present invention, the above-mentioned heating and pressure treatment can effectively open the bonding bond of zirconia and silicon dioxide in the zircon powder, realize sufficient debonding, and the debonding rate can reach 98% The above; pickling has the effect of removing impurities, and drying can fur...

Embodiment 1

[0029] The preparation method of a vanadium-zirconium blue material in this embodiment is to heat and pressurize the zircon powder, the temperature of the heat treatment is 350°C, the pressure of the pressure treatment is 0.4MPa, and then the And the zircon powder after the pressure treatment is pickled to neutrality with a mass concentration of 1% sulfuric acid or hydrochloric acid, and the Al 2 o 3 , Fe 2 o 3 、TiO 2 and P 2 o 5 The mass concentration of impurities is 0.1%. The pickled zircon powder is first dried and then ground to control the particle size of the zircon powder to 5 μm to obtain the pretreated zircon powder.

[0030] The zircon powder, vanadium pentoxide and sodium chloride after the pretreatment method of the above-mentioned zircon powder pretreatment (also can add other vanadium zirconium blue material preparation raw materials in the prior art) are evenly mixed to obtain a mixture , first grind the mixture, then heat the mixture at a uniform speed ...

Embodiment 2

[0032] The preparation method of a vanadium-zirconium blue material in this embodiment is to heat and pressurize the zircon powder, the temperature of the heat treatment is 400°C, the pressure of the pressure treatment is 0.6MPa, and then the And the zircon powder after the pressure treatment is pickled to neutrality with a mass concentration of 2% sulfuric acid or hydrochloric acid, and the Al 2 o 3 , Fe 2 o 3 、TiO 2 and P 2 o 5 The mass concentration of impurities is 0.01%. The pickled zircon powder is first dried and then ground to control the particle size of the zircon powder to 10 μm to obtain the pretreated zircon powder.

[0033] The zircon powder, vanadium pentoxide and sodium chloride after the pretreatment method of the above-mentioned zircon powder pretreatment (also can add other vanadium zirconium blue material preparation raw materials in the prior art) are evenly mixed to obtain a mixture , first grind the mixture, then heat the mixture at a uniform spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com