Method for preparing graphene coated protective metal lithium microspheres

A graphene-coated, metal lithium technology, applied in electrical components, electrochemical generators, battery electrodes, etc., can solve problems such as unfavorable application of lithium-ion batteries, and achieve the effect of excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

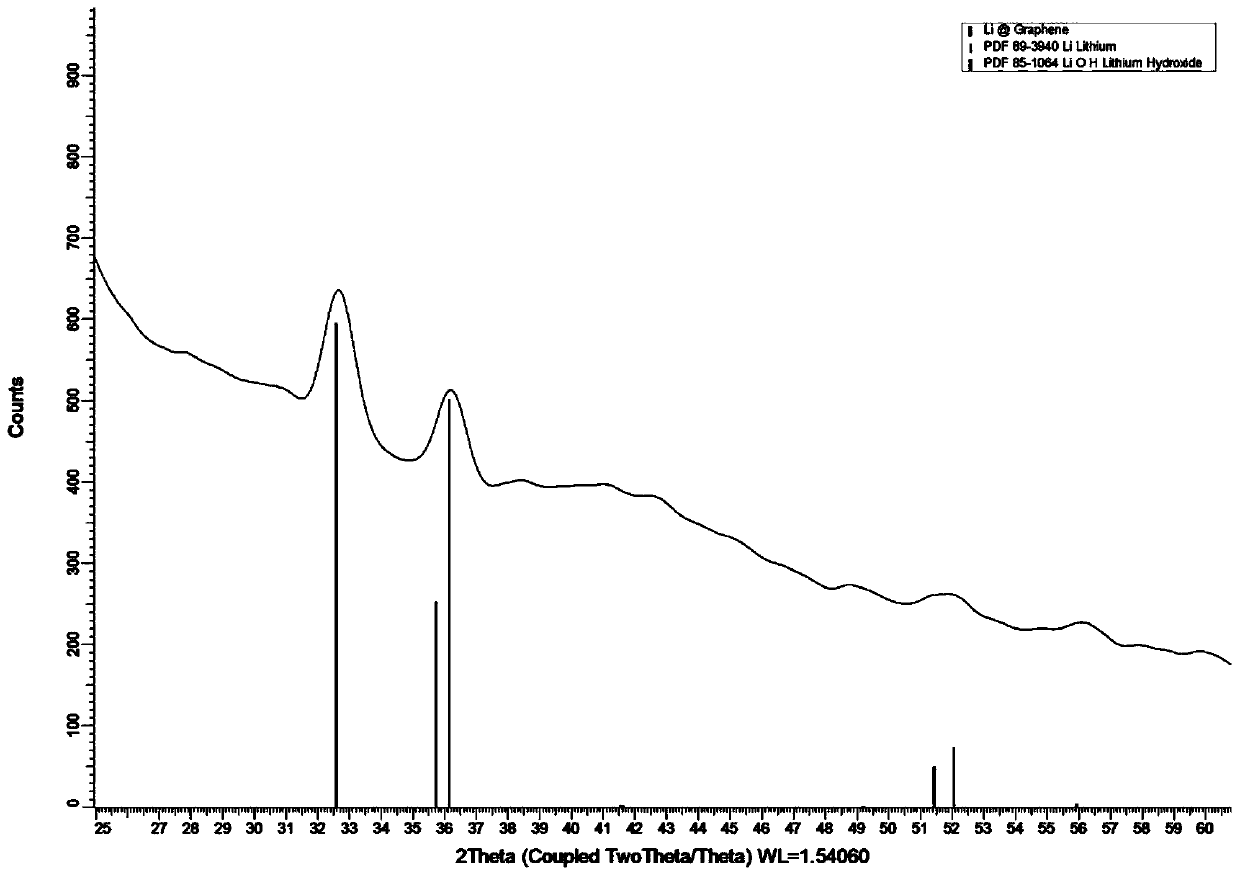

[0020] A preparation method for graphene-coated and protected metal lithium microspheres, comprising the steps of:

[0021] S1. Weigh 80-90mg of lithium metal, add it to 25-35ml of inert solvent, heat the lithium metal in the inert solvent to melt the lithium metal, and disperse it by high-shear stirring to make the molten lithium metal in the inert solvent Micron-sized particles are formed, and then the temperature is lowered to solidify the lithium metal to form a lithium metal microsphere dispersion;

[0022] S2. Weigh 50-60 mg of surface carboxyl-modified graphene after sanding treatment, add it to 25-35 ml of inert solvent, and then perform ultrasonic dispersion treatment for 5-10 minutes to form a uniform and stable graphene dispersion;

[0023] S3. Mix the metal lithium microsphere dispersion in step S1 and the graphene dispersion in step S2, fully stir for 30-40 minutes, filter and separate the inert solvent or evaporate and dry it to prepare graphene-coated and protec...

Embodiment 2

[0028] A preparation method for graphene-coated and protected metal lithium microspheres, comprising the steps of:

[0029] S1. Weigh 80-90mg of lithium metal, add it to 25-35ml of inert solvent, heat the lithium metal in the inert solvent to melt the lithium metal, and disperse it by high-shear stirring to make the molten lithium metal in the inert solvent Micron-sized particles are formed, and then the temperature is lowered to solidify the lithium metal to form a lithium metal microsphere dispersion;

[0030] S2. Weighing 50-60 mg of surface hydroxyl-modified graphene after sanding treatment, adding it to 25-35 ml of inert solvent, and then performing ultrasonic dispersion treatment for 5-10 minutes to form a uniform and stable graphene dispersion;

[0031] S3. Mix the metal lithium microsphere dispersion in step S1 and the graphene dispersion in step S2, fully stir for 30-40 minutes, filter and separate the inert solvent or evaporate and dry it to prepare graphene-coated a...

Embodiment 3

[0034] A preparation method for graphene-coated and protected metal lithium microspheres, comprising the steps of:

[0035] S1. Weigh 80-90mg of lithium metal, add it to 25-35ml of inert solvent, heat the lithium metal in the inert solvent to melt the lithium metal, and disperse it by high-shear stirring to make the molten lithium metal in the inert solvent Micron-sized particles are formed, and then the temperature is lowered to solidify the lithium metal to form a lithium metal microsphere dispersion;

[0036] S2. Weigh 50-60 mg of epoxy-modified graphene on the surface after sanding treatment, add it to 25-35 ml of inert solvent, and then perform ultrasonic dispersion treatment for 5-10 minutes to form a uniform and stable graphene dispersion;

[0037] S3. Mix the metal lithium microsphere dispersion in step S1 and the graphene dispersion in step S2, fully stir for 30-40 minutes, filter and separate the inert solvent or evaporate and dry it to prepare graphene-coated and pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com