Preparation method of aluminum-oxide-coated nano lithium titanate composite material

A nano-lithium titanate, composite material technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of affecting battery capacity and cycle, easy to generate overpotential, affecting battery performance, etc., to improve battery flatulence problem, Suppression of flatulence problems, guaranteed effect of capacity and cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

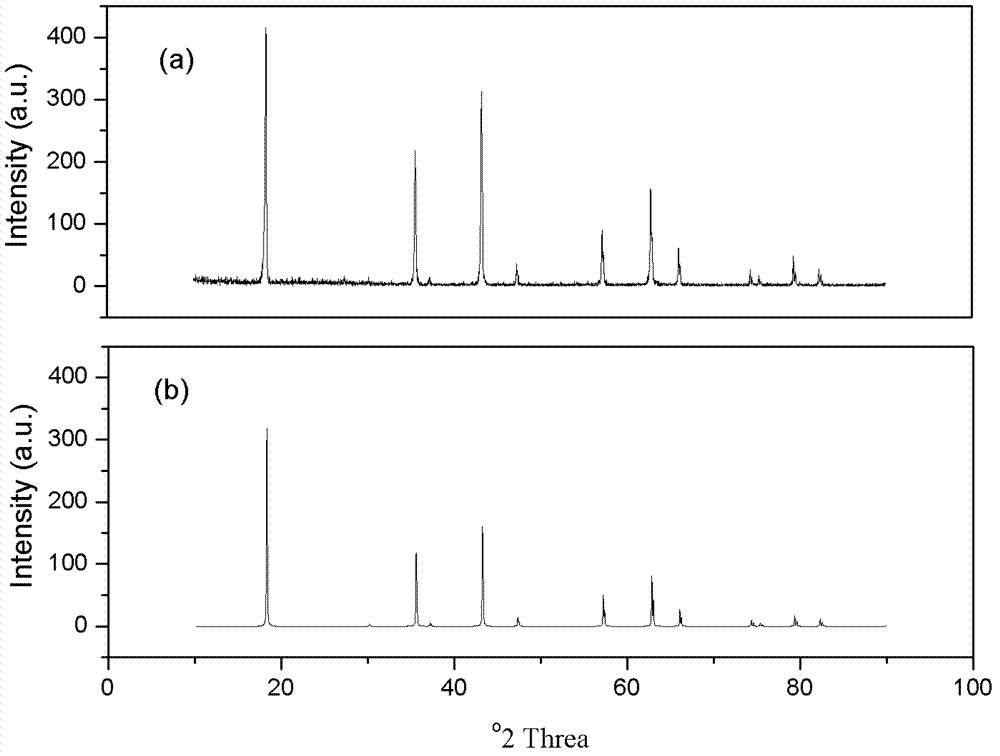

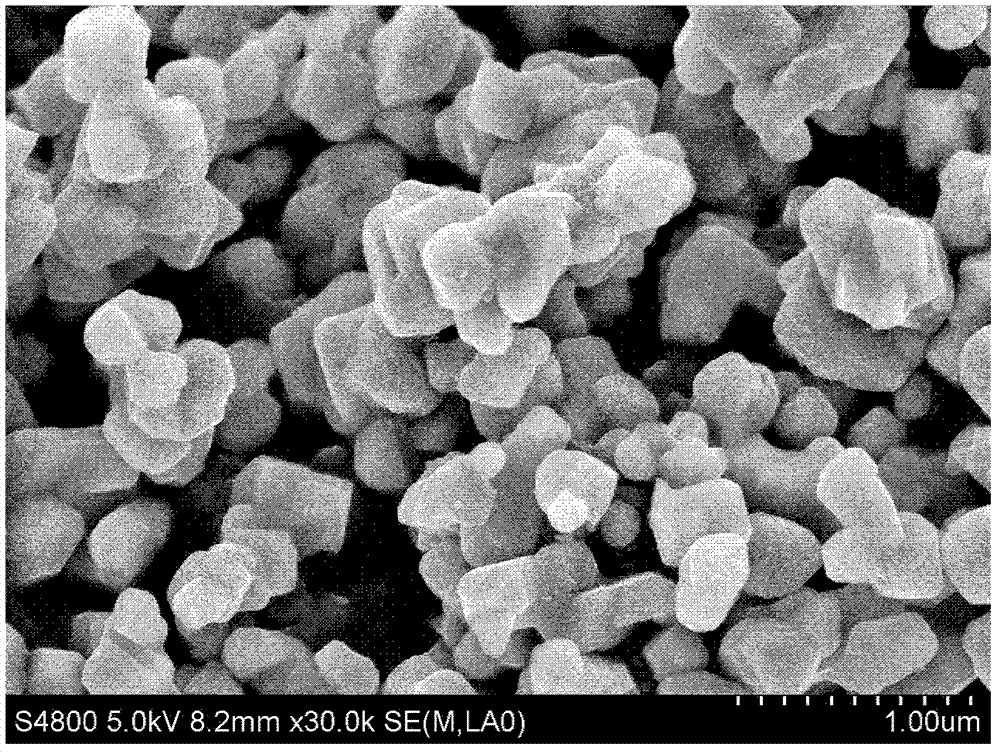

[0025] (1) Weigh the lithium salt and titanium dioxide according to the molar ratio of lithium and titanium elements being 0.8, perform ball milling dispersion treatment with alcohol for 6 hours, and dry the slurry in a drying oven at 80 degrees for 10 hours. Place the dried precursor in an air atmosphere in a muffle furnace and heat it up to 580°C for 2 hours at a rate of 2°C / min, then raise it to 800°C at the same rate for 10 hours, then cool it down to room temperature naturally That is, a pure-phase nano-lithium titanate material is obtained.

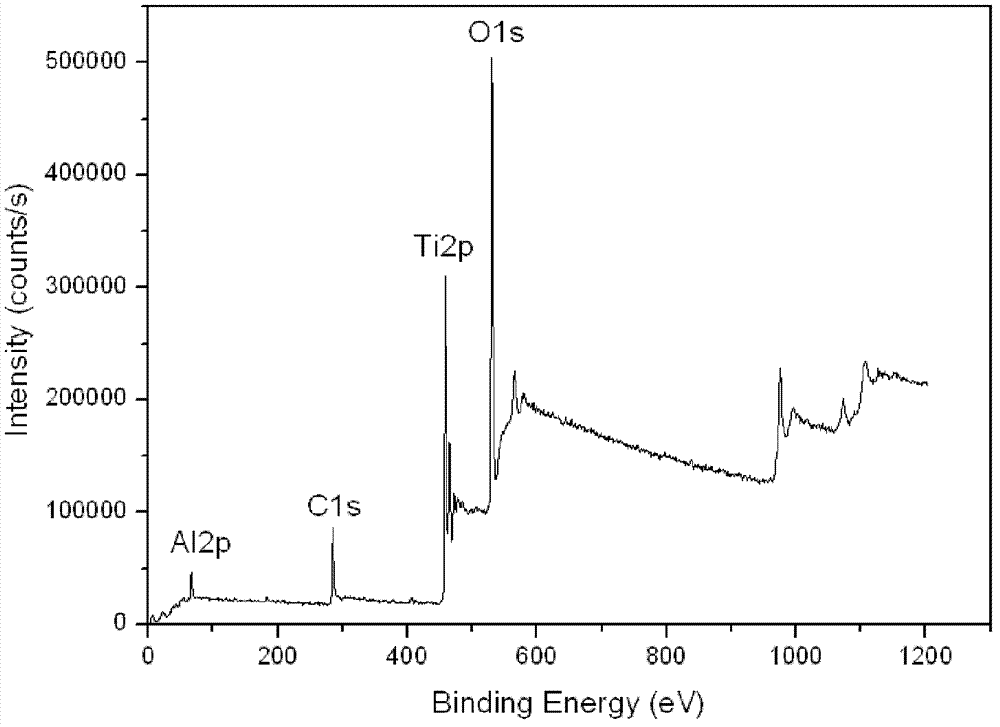

[0026] (2) Using deionized water as a solvent, add a certain amount of polyammonium methacrylate, and disperse the nano-lithium titanate powder. First use ultrasonic vibration for about 20 minutes, then stir and heat in a constant temperature water bath at 50°C for about 30 minutes to obtain a uniformly dispersed and stable suspension, in which the mass percentage of ammonium polymethacrylate is 0.5%.

[0027] (3) Add AlCl to the l...

Embodiment 2

[0030] (1) Weigh the lithium salt and titanium dioxide according to the molar ratio of lithium and titanium elements being 0.82, perform ball milling dispersion treatment with alcohol for 8 hours, and dry the slurry in a drying oven at 100 degrees for 10 hours. Place the dried precursor in an air atmosphere in a muffle furnace and heat it up to 600°C for 4 hours at a rate of 5°C / min, then raise it to 850°C at the same rate for 12 hours, then cool it down to room temperature naturally That is, a pure-phase nano-lithium titanate material is obtained.

[0031] (2) Using deionized water as a solvent, add a certain amount of polyammonium methacrylate, and disperse the nano-lithium titanate powder. First use ultrasonic vibration for about 20 minutes, then stir and heat in a constant temperature water bath at 60°C for about 30 minutes to obtain a uniformly dispersed and stable suspension, in which the mass percentage of ammonium polymethacrylate is 1.5%.

[0032] (3) Add AlCl to the...

Embodiment 3

[0035] (1) Weigh the lithium salt and titanium dioxide according to the molar ratio of lithium and titanium elements being 0.84, perform ball milling and dispersion treatment with alcohol for 10 hours, and dry the slurry in a drying oven at 120 degrees for 12 hours. Place the dried precursor in an air atmosphere in a muffle furnace and heat it up to 650°C for 6 hours at a rate of 10°C / min, then raise it to 900°C at the same rate for 14 hours, then cool it down to room temperature naturally That is, a pure-phase nano-lithium titanate material is obtained.

[0036] (2) Using deionized water as a solvent, add a certain amount of polyammonium methacrylate, and disperse the nano-lithium titanate powder. First use ultrasonic vibration for about 20 minutes, then stir and heat in a constant temperature water bath at 80°C for about 30 minutes to obtain a uniformly dispersed and stable suspension, in which the mass percentage of ammonium polymethacrylate is 2.5%.

[0037] (3) Add AlCl ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com