A preparation method of titanium nitride and carbon double-coated lithium manganese iron phosphate composite material

A technology for coating ferromanganese phosphate and composite materials, which is applied in electrochemical generators, structural parts, electrical components, etc. Unsatisfactory effect and other problems, to achieve the effect of improving cycle stability, high tap density, and simple use of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

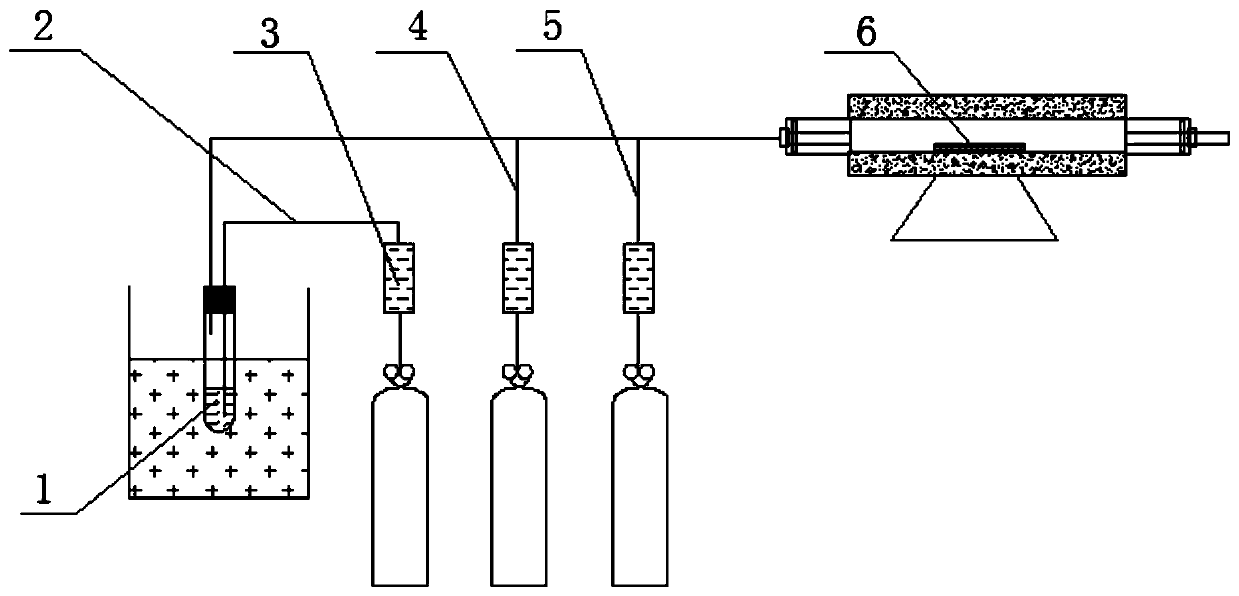

[0030] A preparation method of a titanium nitride and carbon double-coated lithium manganese iron phosphate composite material, specifically comprising the following steps:

[0031] 1) According to the molar ratio of Li:Mn:Fe:P=1.05:0.8:0.2:1, respectively weigh lithium carbonate, manganese acetate, ferrous oxalate and ammonium dihydrogen phosphate for material preparation, and LiMn synthesized according to theory 0.8 Fe 0.2 PO 4 5% of the mass of the material weighed sucrose, lithium carbonate, manganese acetate, ferrous oxalate, ammonium dihydrogen phosphate and sucrose were wet ball milled and dried, and then ball milled to obtain LiMn 0.8 Fe 0.2 PO 4 Precursor;

[0032] 2) Put the above precursors into the tube furnace, under protective N 2 Under the atmosphere, the temperature was raised to 750 °C at a rate of 5 °C / min and calcined for 10 h, and the NH 3 and TiCl preheated to 60°C 4 to N 2 As the carrier gas is passed into the tube furnace, the protective N is con...

Embodiment 2

[0035] A preparation method of a titanium nitride and carbon double-coated lithium manganese iron phosphate composite material, specifically comprising the following steps:

[0036] 1) According to the molar ratio of Li:Mn:Fe:P=1.0:0.5:0.5:1, respectively weigh lithium hydroxide, manganese acetate, ferric oxide and phosphoric acid for preparation, and LiMn synthesized according to theory 0.5 Fe 0.5 PO 4 Weigh glucose at 3% of the mass of the material, wet lithium hydroxide, manganese acetate, ferric oxide, phosphoric acid and glucose through ball milling and drying, and then ball mill to obtain LiMn 0.5 Fe 0.5 PO 4 Precursor;

[0037] 2) Put the above precursor into a tube furnace, raise the temperature to 600°C at a rate of 2°C / min in an argon atmosphere, and heat it for 15 hours, then add NH 3 , TiCl preheated to 60°C 4 to N 2 Pass the carrier gas into the tube furnace separately, control the argon, NH 3 and carrier N 2 The flow rates were 600mL / min, 100mL / min and 2...

Embodiment 3

[0039] A preparation method of a titanium nitride and carbon double-coated lithium manganese iron phosphate composite material, specifically comprising the following steps:

[0040] 1) According to the molar ratio of Li:Mn:Fe:P=1.1:0.6:0.4:1, weigh lithium lithium acetate, manganese oxalate, ferrous oxalate and ammonium dihydrogen phosphate for preparation, and LiMn synthesized according to theory 0.6 Fe 0.4 PO 4 8% of the mass of the material weighs the phenolic resin, and the lithium source, the manganese source, the iron source, the phosphorus source and the carbon source are subjected to wet ball milling and drying, and then ball milled to obtain LiMn 0.6 Fe 0.4 PO 4 Precursor;

[0041] 2) Put the above precursors into the tube furnace, under protective N 2 Under the atmosphere, the temperature was raised to 800 °C at a rate of 8 °C / min for 10 h, and the TiCl preheated to 60 °C was 4 to N 2 as carrier gas, and NH 3 Pass into the tube furnace respectively, control t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com