Non-wettability coating suitable for resisting high-temperature aluminum permeation and preparation method of non-wettability coating

A non-wetting, high temperature resistant technology, applied in coating, metal material coating process, vacuum evaporation coating, etc., can solve problems such as failure, failure of furnace and steel shell, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The present invention also provides a method for preparing a non-wetting coating suitable for high temperature aluminum penetration, the method specifically comprises the following steps:

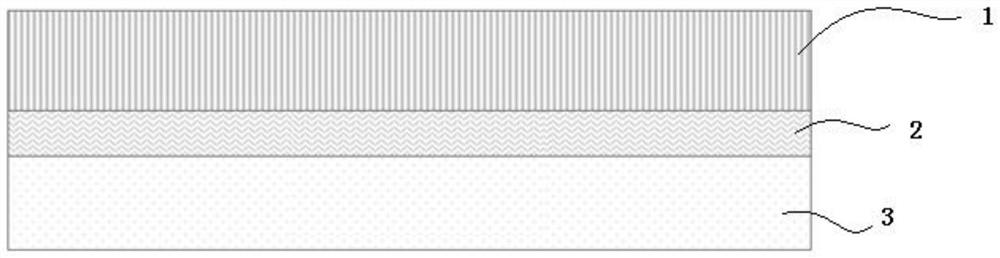

[0025] A dense 50-100 micron thick bonding layer alloy is prepared on the surface of the alloy substrate by atmospheric plasma spraying. Even if the prepared alloy coating has a certain porosity, due to the layered structure characteristics, the pores are not connected to each other. The layer has excellent anti-aluminum propagation effect;

[0026] Prevent the bonding layer from being in the air for a period of time, because it is rich in aluminum, a dense aluminum oxide film will be formed on the surface as an anti-oxidation layer, thereby further protecting the alloy matrix;

[0027] A dense, non-wetting surface ceramic layer with a columnar crystal structure with a thickness of 100-500 microns is prepared on the surface of the bonding layer by electron beam physical vapor deposit...

Embodiment

[0051] A dense 50-100 μm thick bonding layer was prepared on the surface of the alloy substrate by atmospheric plasma spraying. The atmospheric plasma spraying process parameters were as follows: the power of the spray gun was 35~40 kW, the distance of the spray gun was 120~200 mm, and the argon and hydrogen The gas flow rate was 5~8 slpm, 6~12 slpm, the feed rate was 35~60 g / min, the spray gun speed was 100~300 mm / s, and the spraying time was 1~3 min; After a period of time, due to its rich aluminum, a dense aluminum oxide film will be formed on the surface as an anti-oxidation layer to further protect the alloy matrix; the thickness of 100-500 microns is prepared on the surface of the bonding layer by electron beam physical vapor deposition. A dense, non-wetting ceramic layer with a columnar crystal structure that resists aluminum penetration. The parameters of electron beam physical meteorological deposition are: the vacuum degree of vacuum treatment is less than 5×10 -3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com